Soybean Oil Refinery Plant Mectech

- Usage: Soybean Oil

- Production Capacity: 20~2000T/D

- Voltage: 380v/50Hz

- Power(W): up to specification

- Dimension(L*W*H): 1360*950*1170mm

- Weight: up to specification

- Function: processing of Soybean oil machine

- Capacity Model: 10T/H,30T/H,45T/H,60T/H,80T/H,100T/H

- Suitable material: Soybean and such oil material

- Patent product: Yes

- Patent No.: ZL2007 20092291.7;

- Fully automatic: Yes

- Technology support: life time

- Warrenty: one year

- After-sale service: Offering installation and debugging

Today, Mectech is a leading Soybean Oil Extraction Plant manufacturer or Soybean Oil Plant manufacturer in India and abroad with its latest techniques and energy efficient plants. Being one of the leading soya solvent extraction plant suppliers, we have supplied more than 350 plants in different parts of the world on turnkey basis.

This “Pre-feasibility Document” provides details for setting up a “Canola and Soybean Oil Refining and Packaging Unit”. The products produced by the proposed unit include refined canola oil and refined Soybean oils in pouch and bottle packaging. Health considerations make Canola and Soybean oils popular in the masses. An increasing

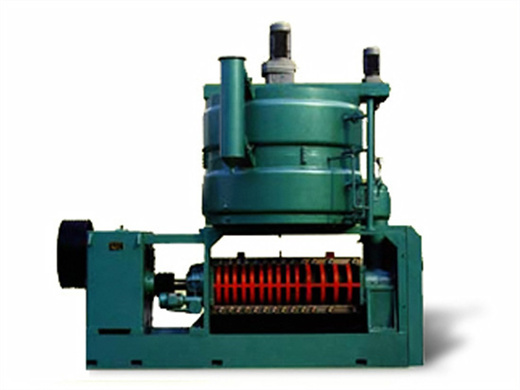

Soyabean Oil Refinery Plant

- Usage: for cooking edible oil

- Type: Oil Pressing Machine

- Production Capacity: 20-2000TPD

- Voltage: 380V

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Note: 2 years spare parts for free

- Color: can be customized

- Capacity: 1-1000TPD

- Material: carbon steel & stainless steel

- Raw material: Soybean

- Advantage: easy use,energy saving,simple operation

- Function: get high quality cooking oil

- Feature: Full Automatic and Multifunction

- Package: Standard

Soyabean Oil Refinery by Tinytech comes in various capacities ranging from entry level small scale plant of 5-TPD to medium and big scale plants upto 30-TPD. We are leading manufacturers and exporters of Soyabean Oil Refinery Plant systems for processing the crude soya oil into the refined soya oil.

The soybean oil refinery plant process is a complex process that requires careful attention to detail. By following these steps, manufacturers can produce high-quality soybean oil that is safe for human consumption and suitable for industrial use.

Soybean Oil Processing Plant IMARC Group

- Usage: Soybean Oil, All kinds of oil seeds

- Type: Oil Extraction Machine

- Production Capacity: 100TPD

- Voltage: 220/380

- Dimension(L*W*H): 1400*860*1260

- Weight: 280 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Other, Gear, Bearing, Engine, Gearbox

- Oil type: Soybean Oil

- Product name: Oli Press Machine

- Function: Making Edible Oil

- Application: Screw Oil Expeller

- Raw material: Soybean

- Advantage: Energy Saving

- Material: 304 Stainless Steel

- Color: Customer Required

- Capacity: 750kg/h

IMARC Group’s report titled “Soybean Oil Processing Plant Project Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a soybean oil processing plant. It covers a comprehensive market overview to micro-level information such as unit

We are manufacturer, exporter & supplier of Soybean Oil Refinery Plant. As per the today's market research it is being concluded that the market demands the refined edible oil with characteristics such as blend flavour and odour, clear appearance, light colour, long shelf life, suitable for frying since the crude oil obtain does contain many harmful factors like free fatty acid, sediments

VEGETABLE OIL EXTRACTION PLANTS Extech Process

- Type: Bath Bombs

- Product name: Bath Bomb Press Machine

- Function: press bath bombs

- Use: making bath ball

- Shape: customized

- Usage: Bath Cleaning Bombs

- Feature: Natural Salts Essential Oil

- Application: Home.Hotel.Bathroom.Shower Room

- Key words: Organic Bath Bomb Natural

Mantora Oil Mill, Kanpur: Solvent Plant: Soybean 600 TPD: Dhanuka Extractions, Neemuch: Solvent Plant Veg oil refinery : Soybean 400 TPD 200 TPD on soya: Years 2009-2012: K S Oils, Guna: Solvent Plant: Soybean 1,200 TPD: 3F Ghana Ltd. Oil Mill Solvent Plant: Shea nut 200 TPD Shea Cake 200 TPD: Gujarat Ambuja Exports Ltd. Solvent Plant: Soybean

Soybean Oil Processing Plant cooking oil refinery plant

- Usage: Soybean oil solvent extraction

- Type: Towline Extractor

- Production Capacity: 50-100 t/d as your requst

- Voltage: 380V

- Power(W): As Soybean oil solvent extraction capacity

- Dimension(L*W*H): As Soybean oil solvent extraction request

- Weight: As Soybean oil solvent extraction request

- Item: Soybean oil solvent extraction

- material: stainless steel

- residual oil in cake: less than 1%

- raw material range: Soybean Oil ,plam kernel ,Soybean ,

- application oil: oil extraction rate more than 25%

- Moisture in meal: 12~13%

- Residual solvent: 300ppm

- Solvent: NO.6 solvent oil

- Solvent consumption: 4kg/t

- Mechanical impurities: 0.2%

Advantages Of Jagdish Soybean Oil Refinery Plant. Today, Jagdish is leading the edible oil refining industry with its latest techniques and energy efficient plants. We have supplied more than 100 plants in different parts of the world on turnkey basis.

- Is soy bean a good crop in Ethiopia?

- Soybean is a multipurpose most nutritionally rich crop as its dry seed contains the highest protein and oil content among grain legumes with a good balance of the essential amino acids and oil. This study was conducted to analyze the trend of soy bean trade in Ethiopia.

- Is soybean farming in Ethiopia irrigated?

- Soybean is grown in high-rainfall areas in the western and north-western parts of Ethiopia. There is no significant irrigation in soybean farming. Value chain analysis of pulses and oilseeds from Ethiopia (October 2018) Page | 84. Pesticides and herbicides are used in soybean farming.

- Where is phibela oil refinery located?

- It is a huge edible oil refinery not only in Ethiopia but also in Africa. The industrial complex is situated at Bure town, in West Gojjam Zone, Amhara National Regional State, and 441 km north of Addis Ababa. Phibela Industrial Complex has been set up with an outlay of 4.5 Billion Birr.