Steps of Cottonseed Oil Processing Process Oil Mill Machinery Oil Refining Machine

- Usage: Cottonseed Oil

- Type: Cottonseed oil extractor, high-tech equipment for Cottonseed oil

- Production Capacity: 150TPD, high

- Voltage: according to capacity

- Power(W): depend on the capacity

- Dimension(L*W*H): 120*100*16m

- Weight: according to capacity

- Finished meal moisture: <13% (adjustable

- Power consumption: ≤ 23KWh/T

- Residual oil in meal: <1%

- Crude oil moisture and volatile matter: <0.3%

- Refining Consumption: 1%

- Phosphoric Acid: 2~3 kg/T Oil

- Waste Bleaching Earth Oil Content: 25% to 35 %

In this section we use Magnetic Separator, Vibrating Sieve, de-stoner, decorticator (Cotton seeds used hammering decorticator). Through cleaning the impurity, you can reduce the lost of oil & improve the oil yield and the environment of production plant. The material has been produced after pretreatment contains the impurities ≤ 0.1%.

To improve the oil yield, oil, and cake quality, we use screening and air separation methods to remove impurities in cottonseed. The cotton seeds are first screened to absorb some dust and short lint. Then they are air separated, which can not only remove various impurities in the cotton seeds but also reduce the lint content of the cotton seeds.

IFC invests Sh32 billion in Kenya’s biofuel project

- Usage: crude Cottonseed oil refining equipment

- Type: crude Cottonseed oil refining equipment

- Production Capacity: 1-2000TPH

- Voltage: 220V/380V

- Power(W): 18.5KW

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- Equipment name: crude Cottonseed oil refining equipment

- warranty: 1 year

- material available: crude Cottonseed oil refining equipment

- texture: stainless steel, carbon steel, alloy steel

- projects done: 1-2000TPD complete oil lines

- markets: America, Europe, Africa, Asia, Australia

- delivery: within 1 month after the payment

- services: engineering, producing ,installation, construction

- Advantage: Energy saving, environment friendly

Eni Kenya is producing the oil in its Makueni pressing plant that was opened in July to process castor, croton, and cotton seeds. Read: IFC to guide Kenya's bank loan pricing reforms

The report provides a complete roadmap for setting up an cotton seed oil processing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. Read

Ginneries and Cotton Distribution in Kenya ICAC

- Usage: automatic Cottonseed oil machine

- Production Capacity: 10-100T/D

- Voltage: 440V

- Power(W): 30-50KW

- Dimension(L*W*H): depend on the capacity

- Weight: depend on the capacity

- Smell: no objection odor

- RI: 1.466~1.470

- Iodine value: 124~39

- cetificates: bv/ce

- original: china

- price: resonable

- acid value: <=4.0

- residual oil: 1%

- mositure: 2%

- Product name: automatic Cottonseed oil machine

by ginning. After this operation, cotton seed is packed in 50Kg. bags each and cotton lint is sold locally to Kenyan textile mills for making yarn while cotton seed is sold to Kenyan oil mills for the processing of edible oils, cattle cakes, soap, chicken feed etc. Ginneries also prepare, among other things cotton seed for

The project's asking price is $27.534 million. Operationally, the edible oil crop farm company is forecast to be cash-positive by Year 3. The output Based on the agroclimatic conditions, Homabay County offers an excellent opportunity to produce edible oil farm crops, including palm oil, sunflower, peanut, sesame, soybean, and cotton seed.

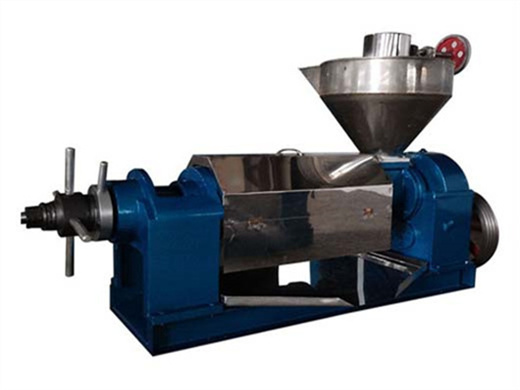

Cotton Seed Processing, Oil Extraction & Refining Plant

- Usage: Cottonseed Oil, Oil Pressers Equipment

- Type: Oil Extraction Machine

- Production Capacity: 30-40kg/h

- Voltage: 220v

- Dimension(L*W*H): 1200*470*1170 mm

- Weight: 200 KG

- Core Components: Motor, Engine

- Oil type: Cottonseed Oil

- Material: Stainless Steel

- Suitable For Raw Material Oil Pressers: Cottonseed,Rapseed,Cottonseed Oil ect.

- Function: Oil Pressing Production Line

- Feature: Multi-functional

- Advantage: High Efficient

- Package: Standard Wooden Case

- Shipping: By sea,by air,by express

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Cottonseed Oil Extraction Plant

- Usage: Cooking Oil

- Type: Oil Extraction Machine

- Production Capacity: 3.5-50kg/h

- Voltage: 220V

- Dimension(L*W*H): 360*155*310mm

- Weight: 7 KG

- Core Components: Motor

- Oil type: Cottonseed Oil

- Raw material: mini oil press machine

- Product name: Cottonseed machine oil extraction

- Press type: screw type

- Function: press oil

- Color: Sliver

- Model: X8S

- Use for: home use

- Delivery: fast delivery

- Material: Stainess Steel

The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor. 2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration. 3.

- Is cotton farming suitable in Kenya?

- Kenya is a good place for cotton farming, with potential for both rain-fed and irrigated production in the Rift valley, Nyanza, Central, Coast, and Western Kenya regions. Under the Government’s Big 4 agenda, cotton and textiles have been identified as key drivers towards expansion of the manufacturing sector.

- What is cotton farming in Kenya?

- Cotton farming in Kenya is primarily concentrated in specific regions that offer suitable agroclimatic conditions for its cultivation. These regions have historically been the best for cotton farming in Kenya.

- How much cotton is produced in Kenya on average?

- On average, Kenya produces around 38000 metric tons of cotton, despite having a production potential of 260,000 tons. Smallholder farmers account for 85 percent of cotton farming activities in the nation.

- What is the best soil for cotton farming in Kenya?

- Cotton farming in Kenya requires well-drained soil for healthy plant growth and fiber production. The soil should prevent waterlogging, as poorly drained soils can lead to root diseases.

- Can ratoon cotton be grown in Kenya?

- Cutting and burning of old cotton stalks is carried out in order to reduce the incidence of pests such as pink bollworm, spiny bollworm, seed bugs, cotton stainers and diseases from one season to the next. However, growing of ratoon cotton is a common practice in eastern and coastal areas of Kenya.

- Where are the key cotton growing regions in Kenya?

- The Eastern region of Kenya, particularly parts of Kitui, Makueni, and Meru counties, is one of the key cotton growing regions in Kenya. This region, with its warm climate and relatively low rainfall, is suitable for cotton cultivation.