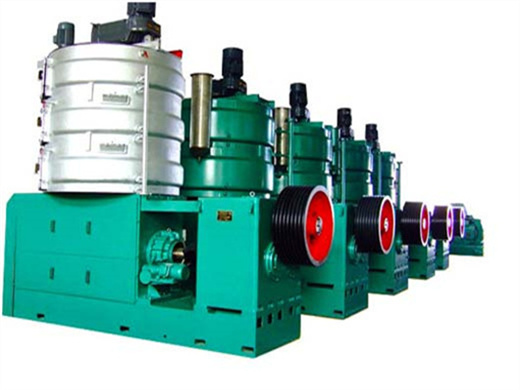

Cottonseed oil production line, Our Oil Machinery

- Usage: Cottonseed oil press for production line

- Type: Oil Pressing Machine

- Production Capacity: 50T~80TPD

- Power(W): 11KW

- Dimension(L*W*H): 2850*1850*3270mm

- Weight: 5000kg

- Production Business type: Manufacturer

- Accepted Delivery Terms: FOB, CFR, CIF

- Guarantee: 12 months

- After sale service: Yes

- Application: Cottonseedetc.

- Certificate: ISO, CE, BV

- Residual oil in cake: <8%

Cotton seed oil production line. Cottonseed oil making process includes: Cottonseed Oil pre-pressing Machine, Cottonseed Oil Extraction Machine and Cottonseed Oil Refining Machine. Cottonseeds can be once-pressed and then sent to the cottonseed oil refinery plant directly.

Cottonseed oil extraction production line solves crude oil extraction from cottonseed cake through processing flows of solvent extracting, mixture oil filtration, wet bran treatment of dephenolizaiton and mechanical desolvent, and low temperature drying, evaporation, gas stripper to obtain crude cottonseed oil. Cottonseed oil extraction plant

Oil Mill Plant Complete Edible Oil Production Lines ..

- Usage: Cottonseed Oil

- Type: Cold & Hot Pressing Machine, Crude Degummed Cottonseed Oil Mill Machinery

- Production Capacity: 10-5000T/D

- Voltage: 220V/380V/415V

- Power: 2.2KW

- Dimension(L*W*H): 1910*550*765 mm

- Weight: 420 KG

- Material: SS/CS

- Application: Cottonseed cake, Cottonseed,etc

- Function: Solvent Extraction Cottonseed Oil

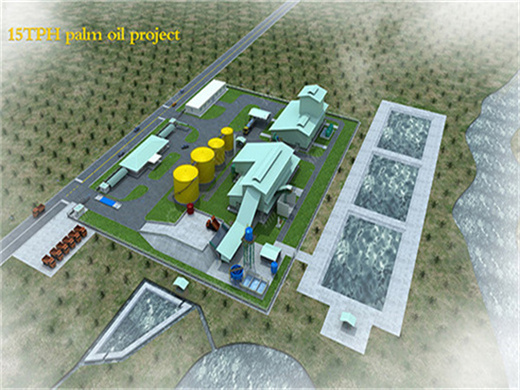

The whole cottonseed oil solvent extraction plant covers the complete production line of the extraction system, desolventizing and toasting system, evaporation system, and condensation system. The Cottonseed Oil Solvent Extraction project is working stably and efficiently.

Our Oil Machinery has developed projects including large-scale oilseed pretreatment and pressing, oil extraction, oil refining and oil fractionation production line project, conveyor equipment project, corn/maize flour, grits, germ milling machines, and corn processing lines, biodiesel technology, cottonseed, rice bran and soybean protein technology, and Palm Oil processing lines, etc. 56

Cottonseed Pre-pressing & Extraction Equipment Professional ..

- Usage: Cooking Oil

- Type: Cottonseed Oil Press Machine

- Voltage: 380V/50HZ

- Dimension(L*W*H): common-use sizes

- Weight: 1 KG, 1kg

- Core Components: Other

- Oil type: Cottonseed Oil, Cottonseed Oil, Cottonseed Beans, Cottonseed

- Product name: Pressure Bar

- Used for: oil press part

- Application: oil press

- Material: 20#

- Delivery time: 7days

The whole oil making machine includes: oil pretreatment machine, oil extraction plant, oil refining line. Pretreatment and prepressing section is a very important section before extraction.It will directly affect extraction effect. Cottonseed oil pre-pressing&extraction craft flow: cottoneseed → clean→seperate → seed ↓ cottonseed hull

the cottonseed oil production process is advanced, with full consideration of low cost, energy saving, environmental protection, and thermal energy recovery and reuse.the process can achieve fully automated control.high-performance, high-quality equipment coupled with Overseas door-to-door installation service ensures long-term stable operation of the equipment.

Cottonseed Oil Production Line

- Usage: all seeds and nuts

- Type: Oil Extraction Machine

- Production Capacity: 5-5.5kg per hour

- Voltage: 110V/220V

- Dimension(L*W*H): 44*23*36cm

- Weight: 12.5 KG

- Oil type: Cottonseed Oil

- Raw material: Oil Seeds

- Application: Screw Oil Expeller

- Material: Stainless Steel 304

- Function: Screw Pressing Oil Seeds

- Advantage: High Oil Yield

- Capacity: Cottonseeds oil mill

- Applied for: Cottonseed ,seasame ,Cottonseed

- Product name: Hemp Oil Extraction Machine

- Item: MINI Oil Extractor

At last, cottonseed oil refining has a special process cottonseed oil fractionation process. It is to seperate the solids and liquids in cottonseed at a specific temperature. Similar with palm oil fractionation process, through cooling, crystallization and filtration, you can get two parts: cottonseed oil olein and cottonseed oil stearine.

Cottonseed Oil Production Line Zhengzhou Siwei Grain & Oil Processing Machine

- Usage: Carrot Juice

- Type: cold screw press

- Production Capacity: 200kg/h-2000kg/h-100%

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 2140*540*1785mm

- Weight: 600 KG

- Core Components: Motor, Bearing, Engine

- Oil type: Cottonseed Oil

- Application: Carrot Juice

- Raw material: SUS304

- Working Capacity per hour: 300-10,000kg

- Product name: Screw Press machine

- Function: Cold Press

- Working Style: Continuous Working

- Lead Time: 15 Working Days

- Advantage: Simple Operation, low cost

Brief Overview of Cottonseed Oil Production Line. 1. The cottonseed oil production process is advanced, with full consideration of low cost, energy saving, environmental protection, and thermal energy recovery and reuse. 2. The process can achieve fully automated control. 3.

- Does a cottonseed oil mill plant need a solvent extraction workshop?

- A cottonseed oil mill plant that has a commercial grade is likely to be compatible with solvent extraction, which requires cottonseed cake solvent extraction workshop, crude cottonseed oil refinery workshop, and cotton seeds pretreatment and pre-pressing workshop.

- What is the oil rate of cotton seed?

- The 18%-22% oil rate is the cottonseed with shell, for your capacity, to get more oil you should dehull the cottonseed before pressing. The oil rate of the cottonseed kernel is 34%-38%. I have send you our cotton seed pictures through email, please advise on cotton seed oil mill factory.

- How to make cottonseed oil?

- Cottonseed oil production plant can be done in 3 ways: Mechanical screw oil pressing, pre-pressing and solvent extraction and direct solvent extraction. Here, let's talk about the cottonseed oil manufacturing process and related equipment. Cottonseeds that have lint will have to go through the delinting machine to remove the lint.

- What are the top features of cotton seed oil expeller machine?

- The top features of cotton seed oil expeller machine are based on the traditional product but include a variety of enhancements, implemented after-in-depth research on cotton seed oil mill plants and also on the characteristics of cottonseed while processing.

- What products can be derived from a cotton oil mill project?

- The following products can be derived from a cotton oil mill project: cottonseed soap stock, cottonseed oil, cottonseed hull, and cottonseed oil. The following features are highlighted in our cottonseed oil manufacturing plant Project: A high percentage of automated tasks for saving labor.

- How to build a top quality cottonseed oil mill plant?

- If you want to build a top quality Cottonseed Oil Mill Plant with or without refning plant, the very first step is to buy high quality oil extraction and refinery machinery - Lesser power consumption, minimum noise during operation and continuous production for better productivity.