Biomass Pellet Mill pellet-richi.com RICHI Machinery

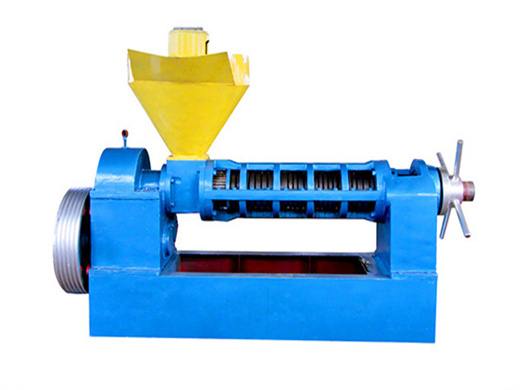

- Usage: Coconut Oil

- Production Capacity: 250-300KG/H

- Voltage: 380V

- Power(W): 3KW

- Dimension(L*W*H): 2000x1200x2500mm

- Weight: 2200kg

- Product name: hydraulic oil press machine

- Material: 316 Stainless Steel

- Barrel Dia: 40cm

- Cake oil rate: 3%

- Pressure: 35-50mpa

- Multi-purpose: yes

- Advantage: Energy Saving

- Color: Clients' requirements

- Raw material: Coconut, Copra

- Movable: Yes

The production of energy by means of biomass has shown a clear trend towards the use of pellets due to their homogeneous size, which facilitates handling and feeding while also reducing costs associated with storage and transportation. The pellet quality depends on the properties of the feedstock and on the operative variables of the densification process. Quality parameters can be modified by

Model Power Size (mm) Net weight (kg) Spindle Speed (r/min) Screen Capacity (kg/h) 420B-7.5: 7.5KW(electric motor) 1200×1000×1220: 285/310: 3200: 1.2-10: 300-600

China Biomass Pellet Mill Manufacturers and Factory

- Usage: Coconut and other

- Production Capacity: 98%-100%

- Voltage: 380

- Power(W): 5.5KW~15KW

- Dimension(L*W*H): 2200*1600*2150

- Weight: 780kg

- Capacity soyabean oil processing plant: 35kg-800kg/h

- Material: Stainless Steel SS304/316

- Residual oil rate: 5~7%

- Raw material: Coconut, Copra

- Advantage soyabean oil processing plant: 36 Years for oil press machine

- Warranty period: 12 months

- Application range: Oil Production Line

- Feature soyabean oil processing plant: High Oil Yield Efficiency

- Function soyabean oil processing plant: Produce High

- Character: Screw Oil Pressing Machines

The features of wood biomass pellet-making machine: 1. Gearbox: Continuing the gearbox advantages of our company's third-generation flat die pellet machine, it adopts high-precision gear transmission and is equipped with an automatic hydraulic circulating oil system to ensure the service life of the gearbox and the working stability of the pellet machine.

GEMCO homemade pellet mill manufacturing high quality biomass pellet mill. We can provide home use pellet mills, complete wood pellet line with competitive price for saw dust, wood shaving, wood chips, corn straw, peanut shells pellet making.

Pellet Mill and Hammer Mill in Biomas

- Type: Coconut oil extract machine

- Use: Coconut oil extract machine

- Product name: Coconut oil extract machine

- Production Capacity: 10-3000TPD

- Voltage: 220V/380V

- Power(W): According to your Capacity

- Dimension(L*W*H): depend on the mode

- Weight: depend on the mode

- Item: Coconut oil extract machine

- Water content in press cake: 40%

- Oil extract rate: 21-23%

In fact, flat die pellet mill also can be divided into 2 types: D-type pellet mill and R-type pellet mill. D-type pellet mill is generally used to process softwood species like pine, fir, cypress, larch, basswood, and also crop waste like straw, stalk, rice husk, peanut shell, grass, etc. It has a rotating flat die and a stationary roller, so

Drying. Before being sent into wood pellet machine, coconut shells should be dried first. Between airflow wood dryer and rotary drum dryer, the latter is chosen for 4t/h coconut shell pellet line because the largest capacity of the former is only 900kg/h which cannot meet the processing requirement.

Cocopeat Pellet Mill/Coir Pith Pellets

- Usage: Oil Extracting

- Type: Cold & Hot Oil Pressing Machine

- Production Capacity: 3 TPD

- Voltage: 380v/50hz

- Dimension(L*W*H): 1250*550*1140

- Weight: 285 KG

- Core Components: Motor, Gear

- Oil type: Coconut Oil

- Oil content of dry cakes: Lower than 8%

- Customizable: Provided

- Field maintenance and repair service: Provided

Ⅱ. Increasing the Added Value of Coco Peat Waste Into Solid Fuel -Bio pellet Globally, interest in using biomass for energy is increasing because of some benefits e.g. reduction of dependency on imported oil, employment creation where biomass fuels create up more employment than coal and oil, environmental benefits which relate to mitigation of greenhouse gas emissions, reduction of acid

Economic Analysis and Guidance of Coconut Shell Pelletizing

- Usage: oil seeds

- Type: coconut oil Processing Equipment

- Production Capacity: 100kg/h

- Voltage: 220v

- Dimension(L*W*H): 1200*400*900mm

- Weight: 695 KG

- Warranty of core components: 2Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Other

- Oil type: Coconut Oil

- Function: Press Oil Seeds

- Feature: with heating

- Machine Material: Carbon Steel/ stainless steel

- Raw material: Coconut/hemp/avocado/mustar

- Package: Steel cage export

- Delivery time: 50-700 Days

- Machine color: white/blue

- Quality: High Level

- After-sales Service Provided: Online support

The coconut pellet plant mainly includes: material crushing, drying, coconut shell pelletizing, pellets cooling, pellets packing. Besides the production output, the following aspects must be considered when you plan to build coconut pellet plant.

- What is coconut shell pellet making machine?

- Coconut shell pellet making machine is a kind ofbiomass pellet machine. At present, coconut shell pellets are mainly used as biomass energy. Our coconut shell pellet mill is also suitable for various agricultural and forestry wastes such as palm husk, rice husk, peanut husk, bamboo shavings, straw, grass and so on.

- What is a coconut shell pellet production line?

- A coconut shell pellet production line consists of several steps, where acoconut shell pellet press is the main machine. Coconut shell pellet making machine is a kind of biomass pellet machine. At present, coconut shell pellets are mainly used as biomass energy.

- What is Richi coco peat biomass pellet mill?

- RICHI coco peat biomass pellet mill s process coconut-based materials for use as fertilizer, mainly used as soil amendment, potting mix, and can also be used as bedding for animals such as rabbits because it has good water absorption. Nowadays, many people use coconut husk, coconut shell and coir pith to process fuel particles.

- How to process coconut shell pellets?

- Due to the quite hardness of the coconut shell, the coconut shell needs to be crushed from big chunk to small pieces by special coconut shell crusher. 2.Drying process in coconut shell pellet processing line For containing certain moisture, crushed coconut shell enters drying machine through conveyor and feeding machine.

- Can coconut husk be used as a fuel pellet machine?

- If you know the calorific value of coconut shell and calorific value of coconut husk , you will be happy to use coconut husk biomass as a raw material to process fuel pellets. In addition, coconut coir cat litter is also one of the important applications of coco peat pellet machine.

- What are coconut shell pellets used for?

- At present, coconut shell pellets are mainly used asbiomass energy. Our coconut shell pellet mill is also suitable for various agricultural and forestry wastes such as palm husk, rice husk, peanut husk, bamboo shavings, straw, grass and so on. Coconut husk and shells are an attractive biomass fuel and are also a good source of charcoal.