Castor Oil Press Machine, Castor Oil Expeller

- Usage: Cooking Oil

- Capacity: 400-500 kg/h

- Voltage: 380 V

- Dimension (L*W*H): 2200*1460*1750

- Weight: 1800 KG

- Main components: Motor

- Oil name: Sunflower cooking oil pressing machine

- Keyword: machine oil presser

- Keyword: hot and cold oil press machine

- Overall dimensions (mm): 2200*1460*1750

- >Squeezing speed worms (r/min): 36

- Main machine configuration power (kw): 22

- Weight (kg): 1800

The castor oil produced is used for industrial applications and the residual oil rate is 6-8%. Castor oil machine features convenient operation, easy maintenance, and stable performance. Adopt helical gear design, castor oil expeller has high transmission efficiency, saving energy.

Read more: 4 Factors To Consider With Cold Pressed Oil Processing. In summation. An expeller press can become a hot press or a cold press, depending on the steps you take upstream before extraction. Equating an expeller with hot pressing isn’t quite accurate because the screw press has nothing to do with the processing temperature.

Screw oil press machine oil mill machine manufacturer

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Oil purity: pure

- Function: vegetable oil, sunflower oil, soybean oil filter

- Oil quality: high stage, food stage

- Price: factory price, lowest price

- Advantage1: Easy operation

- Advantage2: Energy saving

- Working time: 24 hours

- Section: Filtering

- Processing types: Various oil machines

- Packaging details: Plywood

- Transportation package: Wood plywood

- Specification: depends on capacity

- Capacity: 600 sets/month

Outstanding features of screw oil expeller. Screw oil press machine has high oil yield and production efficiency, ranging from 30-600kg/h. Thus, screw press oil extractor is labor-saving and suitable for industrial use. Besides, the screw press extraction has the special advantages of automatic temperature control and one-time pressing.

Screw Oil Expeller Application Screw oil presses are more suitable for medium-sized and small-sized grain and cooking oil processing factories or specialized households. They can press particle oil materials and powder oil materials, such as rapeseeds, cotton seeds, soybeans peanuts and sesame etc.

Oil Expeller Screw Oil Press Manufacturer, Supplier & Exporter

- Usage: Cooking Oil

- Capacity: 5TPD-100TPD

- Voltage: AC220V 50HZ

- Dimension (L*W*H): 600*306*775mm

- Weight: 50 kg

- Main components: Motor

- Oil type: Cooking oil

- Raw material: Oilseeds

- Name: small oil extraction machine

- Function: Making Edible Oil

- Product name: small oil pressing machine

- Advantage: energy saving, operation simple

- Price: factory price

- Material: stainless steel

- Color: silver

- Capacity: 20 kg/h

- Certification: ISO,CE

Below are the details of Models, Capacity, and Power of our Oil Expeller Machines: Various models of our Screw Oil Presses provide a wide range of oil mill solutions for your requirements on the extraction process : small capacity (starting from 1 ton/day) for pressing of edible oilseeds to medium scale processing capacity (starting from 15 tons/day) to large scale processing capacity

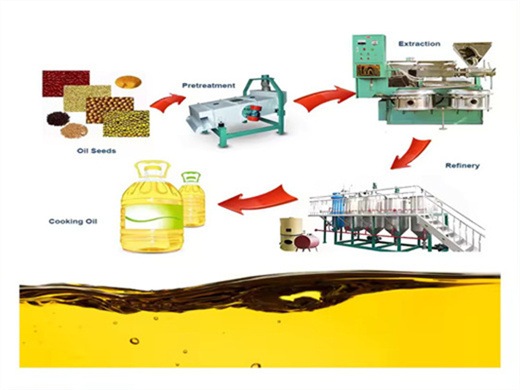

Use screw oil mill machine (expeller) for pre-pressing to get initial oil. Then pre-pressed oil cakes will go through solvent extraction process. Hot Pressing: It means the oil plant includes cooking process. Hot oil pressing utilizes heat and mechanical pressure to extract oil from seeds and nuts. It is featured of high yield of oil recovery.

Castor Oil Manufacturing Process Flowchart How to Start a ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 95%

- Voltage: 220V/380V

- Power (W): According to capacity

- Dimension (L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Function: Refining

- Description: Fully continuous

- Application: Oil production line

- Range of application: Sunflower seed, Cotton seed, etc.

- Color: Silver

- Steam consumption: 450kg/T Oil

- Electric consumption: 28kwh/T Oil

Here are the basic steps to extract the castor oil. Step 1: Castor Seed Dehulling. Step 2: Castor Seed Cleaning. Step 3: Castor Seed Cooking. Step 4: Castor Seed Pressing. Step 5: Castor Oil Clarification. Step 1: Castor Seed Dehulling. Castor seed contains about 30%?35% oil. The extraction process begins with the removal of the hull from the

Screw Oil Press Oil Expeller Taizy Machinery Co., Ltd

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 30 kg per hour

- Voltage: Customer demand

- Dimension (L*W*H): 1150*850*1250

- Weight: 268 KG

- Key selling points: Automatic

- Marketing type: Ordinary product

- Machinery test report: Provided

- Video outgoing inspection: Provided

- Core components warranty: 1 year

- Main components: motor

- After-sales service provided: engineers available to repair machinery abroad

- color: customized

- Certification: ISO9001

The design model of the screw oil press can be small, medium, and large, which can meet all the needs of small oil mills, large oil mills, and edible oil processing enterprises. The production principle of this oil expeller is very simple, mainly by using the mutual squeeze friction between the machines to break the raw material crops and

- What is castor oil press machine?

- Castor oil press machine is used for pressing castor bean for oil. There are semi-automatic castor oil press and automatic castor oil press. The castor oil produced is used for industrial applications and the residual oil rate is 6-8%. Castor oil machine features convenient operation, easy maintenance, and stable performance.

- What is castor oil extraction machine used for?

- Having wide applications, castor oil extraction machine can also process peanut, rapeseed, soybean, sunflower seed, camellia seed, cottonseed, copra, palm kernel, corn germ, sesame, walnut, etc. Castor bean shelling machine is available for shelling the castor seeds.

- What is castor oil used for?

- The castor oil produced is used for industrial applications and the residual oil rate is 6-8%. Castor oil machine features convenient operation, easy maintenance, and stable performance. Adopt helical gear design, castor oil expeller has high transmission efficiency, saving energy.

- How oil expeller Machine Works?

- The working principle of the oil expeller machine is to forcefully push the oilseeds and nuts through the barrel by the action of the revolving worm. Due to increased pressure of worms, the oil squeezed out from the seeds and turns out through holes. After pressing, the crude oil and oil cake are obtained.

- Which country exports castor oil?

- India is also the largest exporter of castor oil and China is the largest importer. Netherlands, France, Germany, and the USA are other major castor oil exporters and importers. Share It With Friends!

- What are the advantages of semi-automatic castor oil machine?

- Semi-automatic castor oil machine is suitable for specialized households, small and medium oil processing plant as well as pre-pressing in solvent extraction plant. 2. Simple structure, strong applicability, easy operation, suitable for continuous operation. 3.