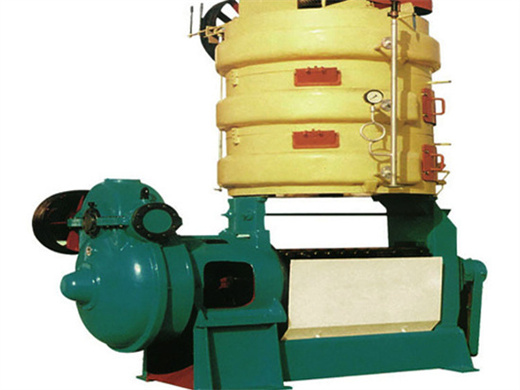

oil pressing machine in ndola edible oil machine supplier

- Usage: Cooking Oil

- Capacity: 100 kg/h~300 kg/h

- Voltage: 380 V

- Power (W): 18.5 KW

- Dimension (L*W*H): 2500*1600*2500

- Weight: 1800kg

- Certification: ISO9001

- Production item: pepper seed oil press

- Plant: 30~50 square meters

- Business type: Manufacturer

- Accepted delivery terms: FOB, CFR, CIF, EXW

- Packaging: Wooden package

- Suitable objects: cooking, etc. .

- Brand: Qi' ;mi

50t combined helix oil pressing machine in ndola. Brick Processing: Brick Production Line; Method: Vacuum Extruder; Automatic: Yes; Production Capacity (Pieces/8 hours): 12000 pcs/8hours, 25~30 million PSC a year

Hot pressing: Usually the castor seeds are heated by hot air at about 120°C to adjust them to a lower humidity, and then pressed in a hydraulic press or screw press to obtain castor oil. Hot pressing can increase the oil yield, generally reaching about 45%, but high temperature may affect some of the nutrients in castor oil.

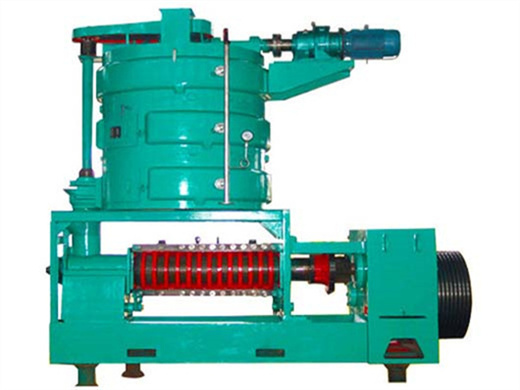

seed oil press machine in ndola edible oil machine supplier

- Usage: Edible Oil

- Model number: oil making mill

- Product voltage: 220/380 Or other

- Residual oil in flour: ≤ 1%

- Capacity: 20-2000TPD

- Steam consumption: ≤ 280 KG/T (0.8 MPa)

- Energy consumption: ≤ 15KWh/T

- Raw material: sunflower, peanuts, soybeans, etc.

- Material: Stainless steel and carbon steel

- Price: Negotiation

sesame oil pressing machine; castor oil pressing machine; flaxseed oil press extraction refining machine in ndola. Production Capacity:10T-3000T/D; Model Number:DT;

new style small hydraulic oil press machine in ndola. Production Capacity: 1000kg/h; Voltage: 220v; Dimension(L*W*H): 2600*1100*700 mm; Weight: 1800 KG; Key Selling Points: High Safety Level

Castor Oil Press Machine, Castor Oil Expeller

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Automatic grade: Semi-automatic

- Capacity: 100kg/h~500kg/h

- Voltage : 220V/380V

- Power (W): 25kw

- Dimension (L*W*H): 2050*1350*2000mm

- Weight: 2000kg

- Certification: ISO9001

- Raw material: Vegetable seed

- Model: screw press

- Operation: easy operation and energy saving

- Color: according to your requirements

- Clamp screw speed: 28~40r/m

- Installation: guided by engineers

- Relationship gearbox transmission size: 15/38x15/52=1

- Feature: residual is less than 7%

- Item: automatic oil pressed organic camellia oil making machine cold

6. Automatic castor oil machine is suitable for small and medium oil processing plant as well as a private oil mill. Structure and Working Principle of Automatic Castor Oil Machine. Automatic castor oil press machine mainly consists of an automatic control system, pressing part, adjusting part, transmission part, and vacuum filtering device. 1.

It is necessary to refine crude castor oil. QIYI Machinery offer customized oil refinery for different castor oil applications. If you are interested in how the castor is refined, please see more information at oil refinery plant. Below is the main picture about the packing details of castor oil pressing line we offer for a client in Columbia.

Beginner's Guide Of Cold Press Oil Extractor For Castor Oil

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 30-100 tons of oil per day

- Voltage: Adjustable

- Power ( W): Capacity

- Dimension (L*W*H): According to machine

- Weight: According to machine

- Oil grade: Grade 1

- Residual oil in flour: ≤ 1%

- Steel Moisture of finished dish: ≤ 10-13% (adjustable)

- Advantage: Energy Saving

- Raw Material: Oil Plant

- Material: 304 Stainless Steel

- Function: fruit oil refinery machine

By purchasing a cold press oil extractor machine, you can perform castor oil extraction for personal use or small-scale production. [email protected] +86 372 5965148 Home

castor oil extraction machine Oil Mill Machinery Oil Refining Machine

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Model number: JN-30

- Voltage: 380 V

- Power (W): 30 kw

- Weight: 800 kg

- Dimension (L*W*H): 10680*1410*1750mm

- Certification: CE

- Warranty: 1 Year

- name: bay leaf dryer-SS304

- input power: 42KVA

- output power: 30KW

- >temperature: 0~200C(adjustable)

- transmission speed: 0~10m/min(adjustable)

- material: 304# stainless steel

- conveyor belt: Teflon

- magnetron: Panasonic

- Dimension (L*W*H): 10680*840*1750mm (can be specially designed)

What's more, this castor oil extraction machine can be used to press various oil bearing materials. Depending on oil content of the particular crop you are pressing, the machine will extract 90-95% of it. So for canola and sunflowers, you will get about 300kgs per ton. Soybeans yield are about half and the remaining cake is worth more for

- How is castor oil processed?

- The processing of castor oil from castor oil plant seeds is done in a similar way to most of other oilseeds. The ripe castor seeds are allowed to dry before being split open to discharge the seeds. The seeds are cleaned, cooked and dried prior to extraction. Cooking is done to coagulate protein, and to press the oil efficiently.

- What is castor oil refining?

- Castor Oil Refining – Summary The filtered oil (called the crude or unrefined oil) is sent to the oil refinery. The steps to refine the crude oil include: Done to remove the aqueous phase from the lipids, and to remove phospholipids from the oil. The neutralization step is necessary to remove free fatty acids from the oil.

- How to refine crude oil?

- The steps to refine the crude oil include: Done to remove the aqueous phase from the lipids, and to remove phospholipids from the oil. The neutralization step is necessary to remove free fatty acids from the oil. Bleaching results in the removal of coloring materials, phospholipids and oxidation products.