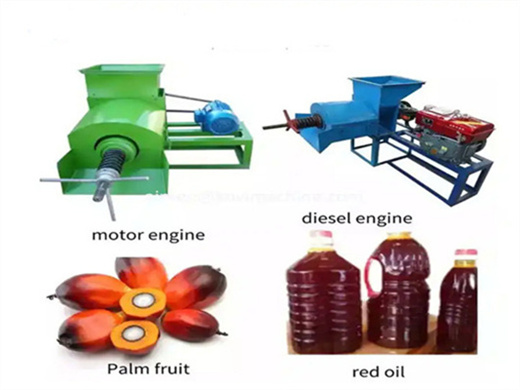

Palm and Palm Kernel Oil Production and Processing Machine

- Usage: Palm oil

- Type: Cooking Oil Press Machine

- Production Capacity: 100-500kg/h

- Voltage: 380V/50HZ

- Dimension(L*W*H): 1700*1300*1600

- Weight: 780kg

- price: low, cheap, best, factory price

- quality: high quality, efficient, performance

- application range: Palm

- capacity: 10t/d, 20t/d, 30t/d, 40t/d, 50t/d, 60t/d, 70t/d, 80t/d, 100t/d

- section: pretreatment, extraction, refining

- scale: mini, small, large scale

- material: carbon steel & stainless steel

- character: screw oil press, combined oil press

- item: Palm oil filter machine

The oil will dissolve in the solvent before being separated in the evaporator to separate the oil from the solvent. The simplified palm kernel oil mechanical extraction process is shown in Fig. 8.4. The basic quality parameters for palm kernel oil and palm kernel cake for export from Malaysia (MEOMA specifications) are shown in Table 8-G.

traditional palm kernel oil processing in ghana process and product characteristics by kwaku fano-debrah a thesis submitted to the department of

REVIEW OF PALM KERNEL OIL PROCESSING AND STORAGE TECHNIQUES

- Usage: Palm Oil

- Type: Palm oil refineries machine

- Automatic Grade: Semi-Automatic

- Production Capacity: high

- Voltage: 220V, 380V, or other

- Power(W): depend on the capacity

- Dimension(L*W*H): depend on the capacity

- Weight: depend on the capacity

- Color: Palm oil refineries machine

- Capacity: 1tpd-200tpd

- Use: oil refinery

- Steam consumption: 450kg/T oil

- Phosphoric acid: 2~3kg/T oil

- Electric consumption: 28kwh/T oil

- Bleaching earth consumption: 5~50Kg/Toil

- Waste bleaching earth oil content: <35%

The ANOVA of the palm kernel oil extraction technique in SouthEast Nigeria showed significant difference in both the study area and oil extraction techniques at 5% level of probability.

POME isn’t the only useful by-product of the palm oil production process. After all, palm oil and palm kernel oil are only a small proportion, about 10%, of all the components of the oil palm tree. POME and empty fruit bunches (EFB) can make up as much as 80% of total mill residues.

Efficient Palm Kernel Oil Extraction Machine

- Usage: Palm Oil

- Type: Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: According to capacity

- Dimension(L*W*H): According to capacity

- Weight: 1000 KG

- Warranty: 1 Year, 12 Months

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Palm Oil

- Raw material: Palm and Palm fruit

- Function: Palm oil or Palm oil

- Application: Oil Production Line

- Advantage: Easy Operation

- Material: Stainess Steel or carbon steel

- Residual oil: less than 1%

- Color: As customized

time required to process palm kernel oil (mins) 300 250 200 150 100 50 0 0 2 4 6 8 number of test PALM KERNEL OIL EXTRACTION MACHINE (MECHANICAL METHOD) TRADITIONAL METHOD Fig. 4 Graph of Time Required to Process Palm Kernel Fruit 10 Oyejide et al. (2018). Design and Construction of a Palm Kernel Oil Extraction Machine.

The use of mechanized extraction of palm kernel oil results in faster oil production, higher daily processing capacity, and more palm kernels can be processed in a shorter period of time. Through the comparison of the above mechanized and the traditional palm kernel extration method, we can clearly find the advantages of mechanized production.

[Beginners Guide] How To Process Palm Oil

- Usage: Palm Oil

- Production Capacity: 300-1000kg per day

- Voltage: 380v,440v,customized

- Dimension(L*W*H): depends on the capacity

- Weight: 100 KG

- Warranty: 1 Year, 1year

- Key Selling Points: Energy saving

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 6 Months

- Core Components: Motor, Pump

- Raw material: Palm Kernel

- Function: Palm

- Advantage: Environmentally friendly

- Feature: easy operating

- Color: as you wish

- workers: 1worker when operating

- Material: stainless steel

- Processing Types: automatic

To process palm oil, begin by harvesting fresh palm fruit bunches and separating the fruit from the bunches. Then, sterilize the fruit, extract the oil by pressing or using a mechanical extraction method, and finally, refine the oil through processes such as clarification and purification to obtain high-quality palm oil.

Palm kernel oil extraction machine, Palm Oil Production Line

- Usage: Palm Oil

- Production Capacity: 30kg per hour

- Voltage: 220v, 220v

- Dimension(L*W*H): 950*800*1000mm

- Weight: 120 KG, 120kg

- Warranty: 1 Year

- Key Selling Points: Energy saving

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- After-sales Service Provided: Free spare parts

- Brand: Gashili

- Power: 1500w

- Dimension: 950*800*1000mm

- Capacity: 30kg/h

If your palm fruit processing capacity is about 1-5 tons/hour, you can choose the standard configuration of palm oil production line equipment, mainly by the fermentation tank, fruit extractor, mashing tank, palm oil press, rotary sieve and plate and frame filter and other equipment, the investment is generally from hundreds of thousands to millions, mostly suitable for medium-sized palm oil.

- How to extract oil from palm kernel paste?

- There are two main methods for extracting oil from palm kernel paste: mechanical extraction and solvent extraction. Mechanical extraction is the traditional method and involves pressing the paste to extract the oil. You can use a manual or motorized press to do this. Read Also: How To Preserve Green Beans For Long Time Storage

- How is palm oil extracted?

- Periodically, the shells are scooped out of the bath and discarded. The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil.

- How are palm kernels extracted?

- The floating kernels are scooped in baskets, washed with clean water and dried. Periodically, the shells are scooped out of the bath and discarded. The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder.

- What are the basic steps in palm oil extraction?

- The basic steps are : Palm Nut is one of the byproduct of Palm Oil Extraction Plants. These Nuts comprise of about 50% Palm Kernel. Proper Separation Technique is necessary to recover the kernels from these nuts. Ripple Mills are used to crack the Palm nuts.

- What is palm oil processing?

- The kernel processors have to go around the palm oil processors during the peak season, when prices are lowest, to purchase the nuts for drying. The nut processing and oil extraction is undertaken in the dry season when the pressure to obtain raw materials has subsided. The traditional palm oil processing starts with the shelling of the palm nuts.

- How is palm kernel oil processed?

- The processing of palm kernel oil involves several stages, including pre-processing, oil extraction, refining, and packaging. Each stage requires specific equipment, skills, and knowledge to ensure the production of high-quality oil that meets market standards.