Professional Palm Kernel Oil Processing Equipment ..

- Usage: Cooking Oil

- Product type:Fruit oil

- Processing type:Refined

- Refined type:Hydrogenated oil

- Cultivation type:Organic

- Use: Season

- Packaging: Bulk, can (canned), drum, glass bottle, glass jar, plastic bottle

- Purity (%) :100

- Volume (L):1234

- Grade: Food Grade

- Product Name:Refined Oil 100% cooking oil

- Flavor:Rich oil flavor

- Quality:100% natural high

- Certified refined oil:Certified raw oil

- SHELF LIFE: 24 months

- Packaging: Customers' demand

- SAMPLE: Available

- MOQ: 27 Mt

- Type of payment: Union - Bank - TT - MoneyGram - LL

More information about palm kernel oil processing process and palm kernel oil processing plant solution, welcome to contact Henan Glory Company. We can design palm kernel oil processing equipment according to your daily capacity and provide corresponding machine. Contact information: My Whatsapp/Wechat: +86 13526627860

Nut & Kernel Separation Station. HongDe is leading & professional palm kernel oil machine manufacturer and supplier in China. We provide complete machine of palm kernel oil processing line at factory price, and undertake turnkey projects for customers. Welcome to consult us for Detailed Quotation. Email: [email protected]

REVIEW OF PALM KERNEL OIL PROCESSING AND STORAGE ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 1-3000TPD cooking seed oil extraction machine

- Voltage: 380/220V

- Power (W): cooking seed oil extract machine

- Dimension (L*W*H): cooking seed oil extract machine

- Weight : cooking seed oil extract machine

- Certification: ISO & CE and BV

- certification: ISO-9001

- warranty: 1 year

- delivery: 30 days after deposit

- color: according to client' requirement

- Function: cooking oil extraction machine

- material: sunflower

- product: raw edible oil and flour

- waste oil : less than 1%

Also, 45% of the processors use machines while 30%, 15%, and 10% of the processors use manual, traditional and solvent methods respectively in extracting oil from the palm kernel in Imo state [38

Nut processing is a complex process that involves several steps and technologies. Proper processing of tree nuts is important to ensure the desired product qualities and nutrient content. Hulling, drying, roasting, and peeling are some of the main techniques involved in nut processing.

How to extract palm kernel oil manually or by automated machine

- Usage: Cooking Oil

- Model number: JN-30

- Voltage: 380V

- Power (W): 30KW

- Dimension (L*W*H ): 10680*840*1750mm

- material: 304# stainless steel

- magnetron: Panasonic

- temperature: 0~200C (adjustable)

- belt: Teflon, mesh belt, link plate

- function: drying, sterilizing, heating, cooking and roasting

- dimension (L*W*H): 10680 *840*1750mm (can be specially designed)

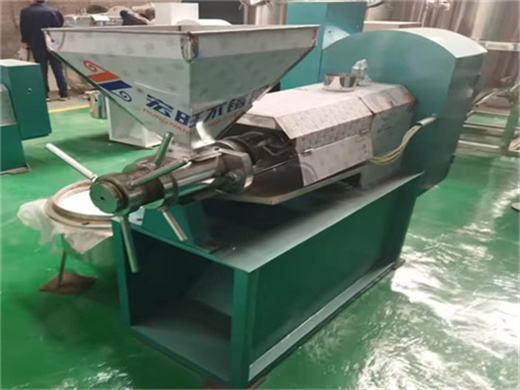

Palm kernel oil expeller. Step 6: Filter the crude palm kernel oil to get the clearer one. The pressed palm kernel oil should be filtered by plate filter, so that a clearer palm kernel oil can be obtained, and the quality of palm kernel oil also be better. The following is the operation video of palm kernel oil production line:

Double screw palm oil pressing machine. The above is palm oil pressing machine and production line, and these palm oil mill machines are popular in Nigeria. Of course, our company also has palm oil refining machines and palm kernel processing machines.

IMPROVING DESIGN MANAGEMENT IN PALM KERNEL NUT CRACKING

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 1-100T/D

- Voltage: 380V/440v

- Power (W) : 20-50KW

- Dimension (L*W*H): 1900*1200*1600mm

- Weight: 500KG

- Main export countries: Asia, Africa , Latin America, Malaysia...

- Packaging: Glass container, Plastic container

- Grade: first grade

- refined oil: 1st grade edible oil

- oil content: 35%-48%

- fat: 40~60.7

- protein: 20~37.2

- phospholipid: 1.25~1.75

- saccharides: 5~15

- Refining type: sunflower seed oil refining plant

improving design management in palm kernel nut cracking and seperating machine analysis March 2021 Journal of Engineering Design and Technology wjert, 2021, Vol. 7,(Issue 2, 36-77.):42

Development and Assessment of Cracking and Sorting ..

- Usage: Cooking Oil

- Capacity: 100-500 tpd oil expeller

- Voltage: 220V/380V/ 440 V

- Power (W): depends on capacity

- Dimension (L*W*H): 5432*2636*2345

- Weight: 850 KG

- Certification: ISO9001

- After-sales service provided: Overseas service center available

- Keywords: cooking oil expeller

- Name : oil ejector

- Material: stainless steel

- Request for engineers: 1-2 engineers

- Oil grade: 1st, 2nd, 3rd

- Environmentally friendly: yes

- Business type: manufacturer

- Methods: cooking oil

- oil rate: 20%-98%

The modified palm nut-fibre separator machine comprises of a feed hopper, a separating chamber with an upper shaft carrying beaters which act as both conveyor and cake breaker and a lower shaft

- How much palm oil is in a palm kernel oil mill?

- Email: [email protected] The palm oil content is very high: common fresh fruit: 46~50%, palm kernel: 50~55%. As professional manufacturer of palm kernel oil mill machine, we can supply complete set of Palm Oil Mill Plant, complete set of palm kernel oil milling plant and complete set palm kernel oil refinery and CPKO fractionation plant.

- How to extract Palm kernel oil?

- For the palm kernel oil plant, there are steps such as nut/fiber separation, nut conditioning and cracking, cracked mixture separation, and kernel drying and storage. To often sell the dried kernels to palm kernel crushers for extraction of crude palm kernel oil.

- Do kernel crushing facilities exist side by side?

- In some integrated plants, kernel crushing facilities exist side by side in the same complex.