Multifunction Process Machine Refined 10 Ton Per Day Processing Plant Palm Oil Refining Equipment in Nigeria

- Usage: Palm Oil

- Type: Other

- Production Capacity: 50-70kg/h

- Voltage: 220V/380V

- Dimension(L*W*H): 1305*1180*1460mm

- Weight: 350KG

- Core Components: Motor

- Oil type: Palm Oil

- Function: Oil Production

- Application: Oil Production Line

- Product name: Small Palm oil press machine for sale

- Color: Custom-made

- Capacity: 50-70kg/h

- Advantage: High Oilput

Single/double screw palm oil press machines. The above is palm oil press machine and production line, and these palm oil machines are popular in nigeria. Of course, our company also has palm oil refining machine and palm kernel processing machine.

5. press: the major function of screw palm oil press machine is to extract palm oil from palm fruit. As for different palm oil processing capacity, there two kinds of screw palm oil press machine for people to choose, one is screw palm oil press machine, the other is double screw palm oil press machine. Screw palm oil press machine. 6.

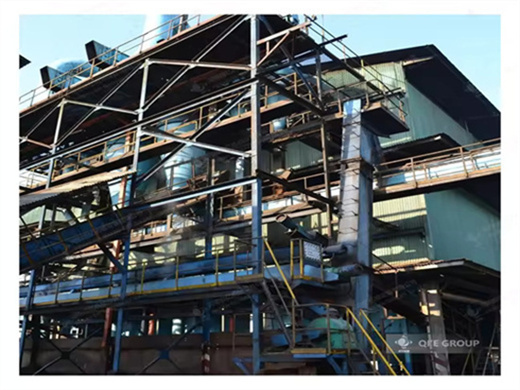

Palm Oil Processing Machinery Manufacturer

- Usage: Palm oil press

- Type: Palm oil press

- Production Capacity: 5-1000 TPD

- Voltage: 220V / 260V / 380V or local voltage, Depend on Palm oil press capacity

- Power(W): Depend on Palm oil press capacity, Depend on Palm oil press capacity

- Dimension(L*W*H): Depend on Palm oil press capacity, Depend on Palm oil press capacity

- Weight: Depend on Palm oil press capacity

- Product name: Palm oil press

- Steam consumption: Depend on Palm oil machine capacity

- Color: Depend on the customers' request

- Residual oil: 4~6%

- Delivery time: 25-45 Days

- Handling capacity: 150~600 kg/h

QIYI Machinery mainly engaged in edible oil raw material pretreatment, pressing, solvent extraction, refining, bleaching, dewaxing, deodorizaiton, palm oil and palm kernel oil pressing, CPO Refining and fractionation, etc.

Here is an introduction to palm oil processing and refining process respectively. Palm oil processing includes sterilization, threshing, digesting and pressing station, oil clarification, and vacuum-dried and stored in oil tanks.

Design and construction of a palm kernel cracker and shell

- Usage: Palm OIL

- Production Capacity: 40-55%

- Voltage: 220v/110v, 220V/110V

- Dimension(L*W*H): 37.5*17.5*30

- Weight: 11 KG

- Warranty: 1 Year, 1 Year

- Key Selling Points: Long Service Life

- Marketing Type: Other

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Raw material: Palm Kernel

- Power: 600W

- G.W: 11KG

- OEM/ODM: Support

- MOQ: 1 set

- After-sales Service Provided: Video technical support

- CBM: 0.02m³

With the ever-evolving palm oil processing industry in Africa, the need for efficient and reliable palm kernel oil processing equipment is also promoting. In order to solve the problem of low efficiency for palm kernel cracking and kernel shell separating, Henan Glory Company has been updating the design and construction of palm kernel cracker.

For the production line required in a small scale palm oil processing plant, we recommend a simple and highly automated palm oil processing production line, which consists of three sets of plants: palm fruit thresher, palm oil press and filter. This palm oil processing production line is very suitable for beginners who want to set up a small.

Palm Oil Production Line, Palm Oil Processing Machine, Palm Oil Refinery Machine

- Usage: Palm Oil

- Type: Oil Extraction Machine

- Production Capacity: 7-2500 kg/h

- Voltage: 220V

- Dimension(L*W*H): 650*300*450 mm

- Weight: 2400 kg

- Core Components: Motor

- Oil type: Palm Oil

- Product name: Hemp extraction machine oil maker machine for home Palm oil press

- Application: Home use

- Feature: High Oil Yield Efficiency

- Keep working: 12h

- Packing size: 650*300*450 mm

- Spare parts: Oil cup, filter screen

- Operate: Automatic

- Raw materials suitable: Kinds of s

- Item: MINI Oil Extractor

Do you have agents in our country? Henan HongDe palm oil processing equipment sold in more than 30 provinces and cities in China and exported to the Nigeria, indonesia, ivory coast Ghana Zambia Namibia C?te d’Ivoire Congo congo Japan, Korea, Bolivia, Sudan, Kazakhstan, Tajikistan, Russia, Uzbekistan Ukraine, Malaysia, Indonesia, togo, Myanmar, Vietnam, Thailand, Rwanda, Peru nigeria.

High Quality Complete Automatic Industrial Palm Oil Processing Plant For Red Fruit Oil Milling Extraction Pressing Milling

- Usage: Palm oil

- Production Capacity: 80-150Kg/h

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1700*1300*1750mm

- Weight: 30ton, 30tons

- Warranty of core components: 2 years

- Core Components: Motor, Pressure vessel, Pump, PLC, Other, Gear, Bearing, Engine, Gearbox

- Oil type: Palm Oil

- Advantage: Energy Saving Low Residual

- Material: steel,carbon steel

- residual oil in meal: less than 1%

- Acid value: less than 1.0mg koh/g

- Function: crude oil refinery to edible oil

- Dimension(L*W*H): : 1700*1300*1750mm

- indine value: 44-46 gl/ 100g

- Raw material: crude vegetable oil

Sourcing Guide for Palm Oil Processing Machine: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: oil press machine, oil processing machine, palm kernel oil extraction machine.

- How to start a palm oil processing plant in Indonesia?

- Establishing a palm oil processing plant in Indonesia is a lucrative opportunity, and a careful understanding of the associated costs is key to success. Key steps include the cost of acquiring suitable land, infrastructure costs, processing machinery costs, and various management and operational costs. Plant Layout and Design:

- Why is equipment layout important for palm oil mills in Indonesia?

- In the construction of palm oil mills in Indonesia, a reasonable palm oil factory plant and equipment layout design is crucial for improving production efficiency and operational safety. Proper equipment layout not only affects the ease of maintenance and repair, but also has a profound impact on the construction investment and economic efficiency.

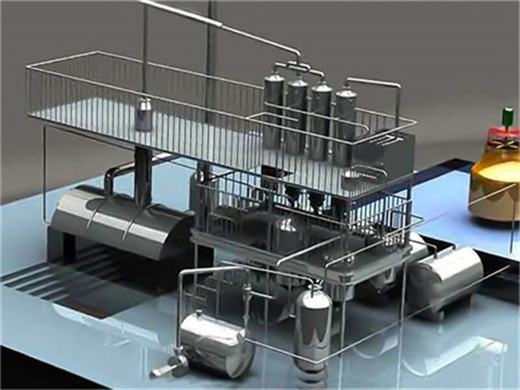

- What is palm oil refining equipment?

- Palm oil refining equipment includes oil-water separation equipment, deodorization equipment, bleaching equipment, etc. to improve the purity and quality of palm oil. 2. Consider Palm Oil Storage And Packaging Areas

- What is palm oil refinery palnt?

- Palm oil refinery palnt offer turnkey palm oil refinery plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing. The production capacity ranges from 1 ton/d up to 400 ton/day. Palm oil fractionation machine can greatly maximize the value of products.

- What is palm oil production process?

- The complete palm oil production process consists of three main parts: palm oil pressing, refining and fractionation. (Of course, you can contact ABC Machinery for customized unique process design for your palm oil mill business.) Oil palm fruit bunches → Sterilizing → Threshing → Digesting → Screw/Hydraulic pressing → Filtration → Crude palm oil

- How to design palm oil mill production equipment layout?

- Palm oil manufacturing equipment layout design should follow the order of the palm oil production process flow, the selected equipment should be reasonably arranged in the workshop to ensure smooth production. Below are some suggestions for general palm oil mill production equipment layout design: