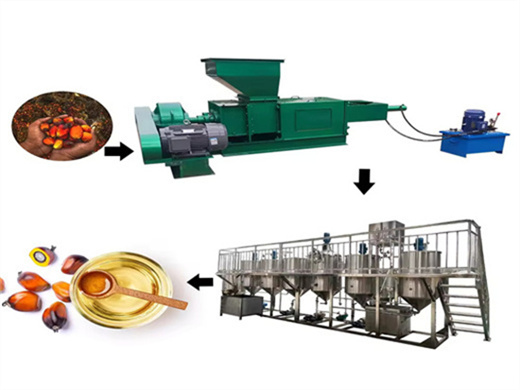

Palm Kernel Oil Manufacturing Process With Flowchart

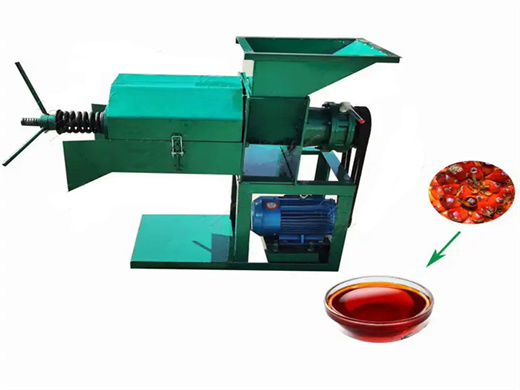

- Usage: Palm OIL, Cooking Oil Extraction Machine

- Production Capacity: 4-32kg/h

- Voltage: 380V, 220V/ 380V

- Dimension(L*W*H): 600*880*1150mm

- Weight: 550 KG

- Core Components: Motor, PLC, Hydraulic system

- Oil type: Palm Oil

- Pressing type: Hydraulic type

- Function: Cold or hot pressing

- Working pressure: 60Mpa

- Oil cake diameter: 185mm

What is the Cost of Setting up a Palm Kernel Oil Production Line? Setting up a palm kernel oil production plant, many aspects must be taken, including production capacity and requirements of customers, the quality of the final produced palm kernel oil, palm kernel oil processing technology, and more.

Find here online price details of companies selling Palm Oil Milling Machine. Get info of suppliers, manufacturers, exporters, traders of Palm Oil Milling Machine for buying in indonesia.

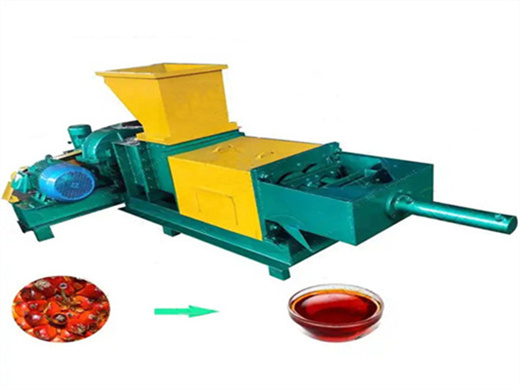

BEST Palm Kernel Crushing Machine Palm Kernel Processing Plant

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, Palm ffb oil process equipment

- Production Capacity: 80kg/h, 500kg/h, 100kg/h

- Voltage: 380V/440V

- Power(W): Capacity

- Dimension(L*W*H): Depend on the capacity

- Weight: Depend on the capacity

- Steam consumption: 450kg/T

- Waste bleaching earth oil content: Less than 35%

- Color: Based on Palm Oil Processing

- Materials of the equipment: stainless steel and carbon steel

- Residual oil in meal: Less than 1%

- Crude oil moisture and volatile matter: Less than 0.30%

- Indine value: 44-46gl/100g

- Acid value: less than 1.0mg koh/g

- Palm fruit reception system:

What’s palm kernel crushing machine? Palm kernel is an edible seed that is obtained from oil palm fruit. This kind of fruit can produce two different oils,one is palm oil that is extracted from the sarcocarp of palm fruit, the other is palm kernel oil that is extracted from the inner side (fruit core).

Shreeji Expeller Industries Offering Palm Kernel Oil Processing Machines, Capacity: 15-18 TPD at Rs 2200000 in Ludhiana, Punjab. Also find Oil Mills price list ID: 27378779633

Palm Kernel Oil Expeller Manufacturers and Exporters in indonesia

- Usage: Palm oil

- Type: Oil Pressing Machine

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 7.5kw

- Dimension(L*W*H): 1910*550*765 mm

- Weight: 1200kg

- Product name: small Palm oil manufacturing plant

- Application: Oil Production Line

- Advantage: Energy Saving

- Warranty period: 12 months

- Material: Carbon Steel Q235

- Item: Vertical Oil Press

- Feature: Multifunction

- Section: Pre Pressing Section

- Raw material: Palm

- Function: Oil Press + One Drum Filter

Palm Kernel Oil % in Cake. 12-14% Oil Present in Cake after 1st Pressing. Less than 7% oil present in Cake after 2nd Pressing; Are you looking for the most suitable and cost effective palm kernel oil expeller machine or complete palm kernel oil production line to start your own oil manufacturing business, then you are in the right place.

Shreeji Expeller Industries is the top most indonesian manufacturer and supplier of oil extraction machinery and components to oil extraction plants, oil mills, oil refinery plants and bio-diesel plant production houses. The company incorporated in the year 1992 was established by Sh. Naresh Kumar Goyal.

Palm Oil Pressing Machine Palm Oil Production Line Palm Oil Refinery Machine

- Usage: Palm Oil

- Type: Automatic Palm Fruit Oil Processing Machine

- Production Capacity: 800KG/H

- Voltage: 380/220V

- Dimension(L*W*H): 1450*870*1180

- Weight: 320 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, PLC, Other, Gear

- Product name: Palm oil press machine

- Keyword 2: oil press and refinery machine

- Keyword 1: mini automatic oil press machine

Separate palm fruit and kernel, and palm oil press machine can obtain CPO (crude palm oil) and palm kernel oil. Main Station Description: 1. Sterilizer As the first step in palm fruit crushing, sterilization is crucial to the quality of palm oil. 2. Threshing The main function of threshing is to separate the palm fruits from the fruit bunches.

Palm Kernel Shell Cracker & Nut Separator Machine

- Usage: Palm Oil Presser

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Power(W): According to the capacity

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Item: Palm Oil Specification

- Material: Stainless Steel 304

- Function: Oil press

- Advantage: Energy Saving

- Feature: High output

- Performance: Excellent

- Color: as your requirement

- Application: Palm,etc.

- Turnkey Project: Yes

Palm kernel cracker, also called palm shell and nut separator machine, is used to crush the hard shell of palm kernel and get the palm kernel nut. Compared to traditional manual separating method, this new type palm kernel cracker machine improve the shell separating efficiency and truly liberate the workers and the work force.

- What is palm kernel expeller press machine?

- Palm kernel expeller press machine is designed using the most advanced technology by experienced professionals. These palm kernel expeller press machine make it easy to extract palm kernel oil. We Henan Doing Company have different types palm kernel expeller press machine for people to choose. Palm kernel oil processing machine

- What is palm kernel oil pressing process?

- Palm kernel oil pressing. Palm kernel oil pressing processing line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing.

- What is palm kernel cleaning & crushing?

- Palm kernel Cleaning : It is used for removing the iron impurities, stone, fiber and pthers. These impurities are bad for machines, especial for the palm kernel oil expeller. ◆ Palm kernel crushing: because the palm kernel is hard and big size, it is required to crash to smaller and even pieces.

- Why is palm kernel oil expeller bad?

- These impurities are bad for machines, especial for the palm kernel oil expeller. ◆ Palm kernel crushing: because the palm kernel is hard and big size, it is required to crash to smaller and even pieces. If once crashing can not reach the requirements, the second crashing is required.

- Which method is used in palm kernel separation?

- Wet separation is mostly used in palm kernel separation, on basis of difference of relative density of palm kernel and shell. ◆ Palm kernel drying. Fresh kernel contains 20% moisture. Palm kernel has no mildew during transportation and storage while moisture drops below 7%.

- How do you crush a palm kernel?

- Crush palm kernels after softening and drying. The centrifugal crusher breaks nuts and separate palm kernel out completely. ◆ Palm kernel and nuts shell separation.