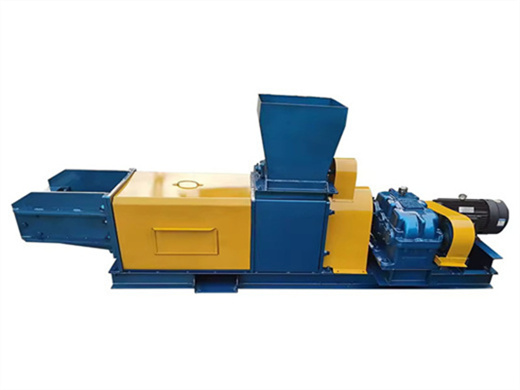

Palm Oil Processing Plant Report 2025: Setup and Cost

- Usage: Palm

- Type: Palm Fruit/kernel Oil Pressing And Refining Machinery Production Line

- Production Capacity: 2000-3000kg/day

- Voltage: 220v/380v

- Dimension(L*W*H): 1510*440*700 mm

- Weight: 350 KG

- Warranty: 1 Year

- Key Selling Points: Long Service Life

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- After-sales Service Provided: Online support

- application: Palm

- Screw diameter: 80mm

- Heater power: 5.5KW

- Capacity: 80-150kg/h

- Feature: High Oil Yield Efficiency

IMARC Group’s report titled “Palm Oil Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a palm oil processing plant. It covers a comprehensive market overview to micro-level information such as unit operations.

Process: The palm fruits are sent to a digester where they are heated to 85°C?90°C and mashed through stirring and squeezing, to destroy the palm skin, separate the palm pulp and nuts, and pound the palm pulp, helping to release the oil in the palm oil pressing process. In small palm oil mill plants, the palm fruit digestion process is.

Small Scale Palm Oil Mill Plant, Equipment for 1-20t/d Production Line

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, extractor de rotocel

- Production Capacity: 30TPD-1000TPD

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Color: Silver

- Production Material: Carbon steel, stainless steel

- Raw material: Palm

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical operating

- Warranty period: One year

- Factory visiting: Yes

One is mini palm oil mill plant for 1~10 ton/day factory, and the other one is 10~20 ton/day palm oil milling plant for small and medium-sized factory. Main Processing Equipments for Crude Palm Oil Mill Plant. The main equipment for small palm oil mill is palm fruits cooking and sterilizing tank, FFB Stripper and screw palm oil press machine.

Palm oil mill process includes 6 parts: Palm fruits receiving, sterilizing, threshing, digesting and pressing, crude oil clarifying and palm kernel recovery. SterilizationThe main purpose of sterilization is to destroy the lipase in the pulp, so as to prevent the free fatty acid content in the oil from increasing. We offer both horizontal and vertical […]

Palm Oil Mill Palm Oil Production Line Palm Oil Refinery Machine

- Usage: Palm Oil

- Production Capacity: 200KG/H

- Voltage: 380V

- Dimension(L*W*H): 2160*525*780mm

- Weight: 500kg

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Palm Oil

- Applicatio: oil s production line

- Capacity: 200KG/H oil press

- Main power: 7.5kw

- Low oil residue in cake: less than 7%

- Matching machines: roaster,filter machine,conveyor etc

- working manual: we can supply

- Advantage: Energy Saving

- Company type: factory and manufacture

Palm Oil Mill process is quite different from other vegetable oil seeds processing. Palm fruits consists a lot of fatty acid enzyme, which would hydrolyze palm oil. That’s the reason why palm fruit must be sent into processing in 24 hours. At the Palm oil mill, the main products that are produced from FFB to Crude Palm Oil (CPO) and Palm Kernels.

After clarification, the purified palm oil can be directly sold or deeply refining. Palm Kernel recovery: After pressing, the palm kernel and fiber mixture can be processed by further separation. After drying, the palm kernels are stored for deep processing, and the separated fiber and shells are used as the boiler fuel for providing steam.

Highly Efficient Palm Oil Milling Process for Palm Oil Mill

- Usage: Palm OIL, Cooking Oil

- Production Capacity: 5TPD

- Voltage: 220V/380V/440V/Customer require

- Dimension(L*W*H): According to capacity

- Weight: 1000 KG

- Core Components: Other

- Oil type: Palm Oil

- Raw material: Palm Oil oil cake

- Function: Solvent extractor oil cake

- Application: Oil production line

- Capacity: 10-500T/D

- Main equipment: Rotocel extractor

- Feature: To extract oil from oil cake

- Color: As required

- Power(W): As capacity

A palm oil milling process plant produces crude palm oil and kernels, as primary products and biomass as secondary product. The capacity of mills varies between 60- 100 tons FFB/h. A typical mill has many operation units as shown in the picture below.

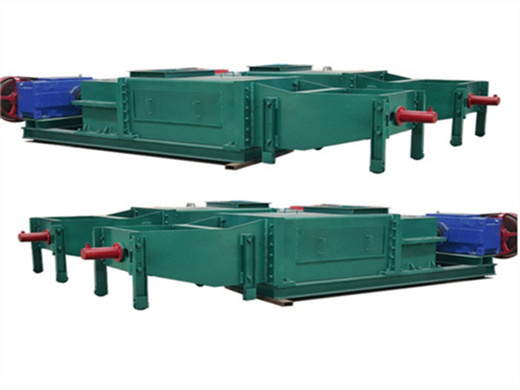

Palm Oil Mill Plant Production Line

- Usage: Palm oil production line

- Production Capacity: 80-150Kg/h

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1700*1300*1750mm

- Weight: 1200kg, 30tons

- Warranty: 1 Year

- Advantage: Energy Saving Low Residual

- Material: steel,carbon steel

- residual oil in meal: less than 1%

- Acid value: less than 1.0mg koh/g

- Function: crude oil refinery to Palm oil

- Dimension(L*W*H):: 1700*1300*1750mm

- indine value: 44-46 gl/ 100g

- Raw material: Palm Kernel

- Keywords: Palm oil production line

- After-sales Service Provided: Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

Nigeria palm oil processing line for sale. Our palm oil mill plant is designed for African conditions, feature a combination of imported special purpose machinery from Malaysia, together with local inputs such as buildings, steelworks, structures, tanks, vessels, etc. 2021-01-28

- Is palm fibre available in Nigeria?

- Palm fibre is readily available in most parts of Nigeria as Nigeria is one of the largest producers of palm oil in the world, with an estimated production of 1.4 million metric tons in the year 2022 . ... ... In palm oil refinery, palm oil mill sludge (POMS) is the solid residue of palm oil mill effluent.

- Is palm oil production a problem in Nigeria?

- Furthermore, the survey of an area in Nigeria was also carried out to ascertain factors affecting the production of palm oil and individual view on the impact of processing. Due to the yield in oil palm enterprise, if the sector is judiciously managed, it will be a source of solution to problems that Nigeria is experiencing.

- How NLNG is helping Nigerians in the oil palm market?

- ill deepen our footprint in the oil palm market.SPONS RSHIPThis proposed oil palm production i n Bonny Island. NLNG is helping Nigerians in appreciat ngthe value of home-made products and aw materials and discouraging the importation of foreigncash crops like palm oil fr

- What is the plant layout of palm oil processing?

- This paper gives an overview of the plant layout of palm oil processing and the scheduling operation, which includes bunch reception, fruit removal, bunches sterilization, digestion of the fruit, extracting of palm oil, clarification of oil, oil storage, and recovery of the kernel.

- Why is palm oil important in Nigeria?

- Palm oil, which is extracted from the fleshy mesocarp of the palm fruit, has been a vital resource in the majority of Nigerians diet. The global need for palm oil is fast increasing because it serves as a source of income. After been refined, the oil is filtered to get a liquid fraction, which is being utilized as cooking oil.

- How is palm oil transported?

- uipment and a 1tph milling machine. There is also a group ofex erienced palm oil experts t achine and other implements. Specialists in the field ofagricultural systems li e irrigation, pl efficient r nning of the entire farm. The transport ofthe produce will be through sea becau e that is the only main means of transporting goods out ofthe