Tian Siang Oil Mill (Perak) Sdn Bhd Tian Siang Group

- Usage: Palm Oil

- Production Capacity: 100TPD

- Voltage: 230-380-430

- Power(W): 40kw/h

- Dimension(L*W*H): 20m*16m*15m

- Weight: 30tons

- After-sales Service Provided: Overseas third-party support available

- Machinery type: Palm oil pressing&extraction plant

- Capacity: 30-1000tons

- Residue in cake: less than 1%

- Extractor type: rotary

- Vacuum degree: high vacuum

- Function: extract oil from

- Solvent type: hexane

- Working mode: circulation usage of solvent and steam

- Solvent in crude oil: 350ppm

- Color: light yellow

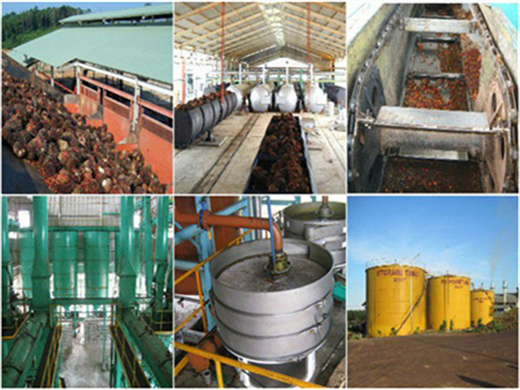

Tian Siang Oil Mill (Perak) Sdn Bhd. Oil palm milling and Biomass Products. Locates in District of Larut Matang Perak, the mill was commissioned in 1997 with FFB processing capacity of 60 tons/hr expandable to 120 tons/hr. Besides the conventional palm oil milling activities, this mill also features the following downstream biomass activities: 1.

Investment in oil palm planting commenced in the 80′s. Tian Siang Plantation Sdn Bhd was incorporated to spearhead the pioneer business venture in 1984 with 1000 acres oil palm planting in the District of Kinabatangan, Sabah and has not looked back since then. In the early 1990s, the group strategized her investment plan and focused.

Overview Tian Siang Group

- Usage: Palm Oil

- Voltage: 380V/220V or as required

- Dimension(L*W*H): 2700*820*1400mm

- Weight: 1800 KG

- Warranty: 1 Year

- Key Selling Points: Energy saving

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: More than 5 years

- Core Components: Motor

- Function: Press Oil Seeds

- Application: Mini Palm Oil Mill Plant

- Advantage: Energy Saving Low Residual

- Capacity: 20t/d

- Material: Carbon Steel Stainless Steel

- Raw material: Palm Kernel

- Processing Types: Screw Pressing

- Used for: various dried oil seeds

- Quality: China Profesional Oil Press Machine

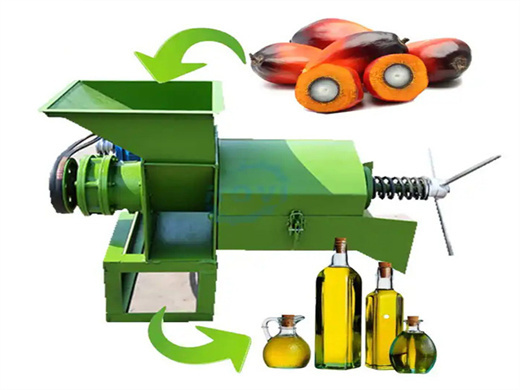

- Product name: household factory direct oil press/Palm Oil Extractor Machine

1. Tian Siang Oil Mill (Perak) Sdn Bhd 340708 K is fully built with a Biogas-Power plant and Long Palm Fibre processing plant. 2. Tian Siang Fibre Industries Sdn Bhd 288345 H and was formed to venture into production of Compost . 3. Tian Siang Biogas Power (Air Kuning) Sdn Bhd 386479 P is formed to venture into Biogas Power plant.

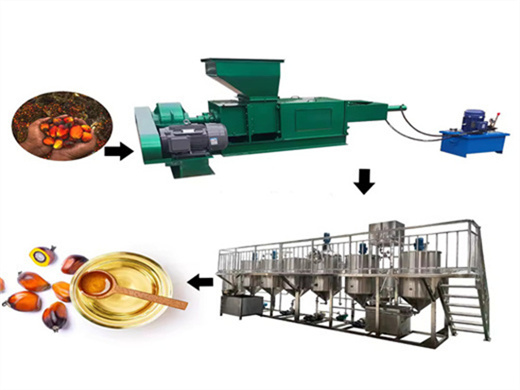

1. Palm kernel oil pressing machine: Next, in the palm kernel oil extraction unit, the roasted palm kernels are transported to the palm kernel oil press machines, where the palm kernels are continuously squeezed by the pressing screw to squeeze out the oil. After pressing, we can get crude palm kernel oil and pressed cake.

Palm Oil Mill Palm Oil Production Line Palm Oil Refinery Machine

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, Manufacturer:

- Production Capacity: 600~700(kg/h)

- Voltage: 380V

- Dimension(L*W*H): 2020X700X1480(mm)

- Weight: 960 KG

- Warranty: 1 Year

- Key Selling Points: Energy saving

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Pump

- Name:: Oil Pressing Machine

- Shaft Speed:: 30~40(r/min)

- Oil Remaining:: 6~8(%)

At the Palm oil mill, the main products that are produced from FFB to Crude Palm Oil (CPO) and Palm Kernels. By products are generated at the palm oil mill, in which crude palm oil (CPO) and kernels are produced from the Fresh Fruit Bunches (FFB). Fresh palm fruit is shipped from the field in bunches or loose fruit.

For example, if your palm fruit processing capacity is about 1-5 tons/hour, you can choose the standard configuration of palm oil production line equipment, mainly by the fermentation tank, fruit extractor, mashing tank, palm oil press, rotary sieve and plate and frame filter and other equipment, the investment is generally from hundreds of thousands to millions, mostly suitable for medium.

Palm kernel oil extraction machine, Palm Oil Production Line

- Usage: Palm Oil

- Production Capacity: 200kg-600kg/h

- Voltage: 380V

- Power(W): 5.5~11kw

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 1200kg

- Advantage: Energy Saving

- Warranty: 1year

- Raw material: Palm

- Delivery time: 20 Days

- Keywords: Oil Press Equipment

- Port: Qingdao/Tianjin/Dalian

- Function: Cold/Hot Press

- Quality: Efficient

Basic Unit Operations of Palm Kernel Oil Extraction Processing: · Palm Kernel Pre-treatment; · Oil Extraction; · Solvent Recovery From Oil and Meal; The following is the main advantages of palm kernel oil extraction machine and plant: 1. Fit for mass production of Palm Kernel Oil Extraction Machine; 2.

Tian Siang Holdings Sdn Bhd Roundtable on Sustainable Palm Oil

- Usage: Palm Oil

- Type: Oil Pressing Machine, Palm oil processing companies in nigeria

- Production Capacity: 1tpd-30tpd

- Voltage: Design according to customer demand

- Power(W): 11 KW

- Dimension(L*W*H): 4935*1523*2664

- Weight: Standard

- Color: Design according to requirement

- Production Material: Stainless steel or carbon steel

- Raw material: Palm

- Work principle: Mechanical extruding

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

? Tian Siang Oil Mill ( Perak) S/B Tian Siang Oil Mill (Air Kuning) S/B Tian Siang Oil Mill (Pahang) S/B Pujaan Makmur Oil Mill S/B (7) The Fresh Fruit Bunches or FFB supply base is 100% from outside sources, consisting mainly from smallholders.

- What is Tian Siang oil mill (Air Kuning) – 288342 a?

- 4. Tian Siang Oil Mill (Air Kuning) Sd Bhd – 288342 A is fully built with Long Palm Fibre processing plant. The integration of the downstream plants synergizes resource utilization and contributes positively in the preservation of a greener environment.

- What is Tian Siang oil mill (Perak) – 340708 K?

- 1. Tian Siang Oil Mill (Perak) Sdn Bhd – 340708 K is fully built with a Biogas-Power plant and Long Palm Fibre processing plant. 2. Tian Siang Fibre Industries Sdn Bhd - 288345 H and was formed to venture into production of Compost . 3.

- How many palm oil mills are there?

- The Group built and commissioned 5 palm oil mills, namely, during 1995 to 2005: The milling operations are further integrated with downstream biomass processing plants which are either fully or partially completed or in the pipeline for implementation in near future. 1.

- Who is Tian Siang fibre Industries Sdn Bhd - 288345 H?

- Tian Siang Fibre Industries Sdn Bhd - 288345 H and was formed to venture into production of Compost . 3. Tian Siang Biogas Power (Air Kuning) Sdn Bhd - 386479 P is formed to venture into Biogas – Power plant utilizing the POME from Tian Siang Oil Mill (Air Kuning) Sdn Bhd - 386479 P.

- How does bio-compost work in oil palm plantations?

- In the presence of special cultured microbes and under controlled aerobic conditions, the mixture is converted into nutrients rich Bio-compost. Applied in complement to the chemical fertilizer, bio-compost serves as soil conditioner and enhancer helping to restore soil fertility in the oil palm plantations.