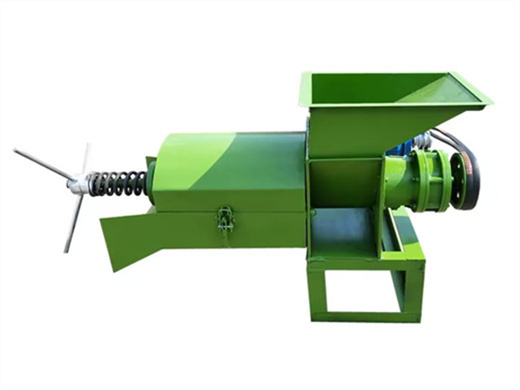

Transesterification of palm oil to biodiesel using Br?nsted

- Usage: Palm Oil

- Automatic Grade: Semi-Automatic

- Production Capacity: 35~550kg/h

- Power(W): 2.5KW

- Dimension(L*W*H): 900*850*1550mm

- Weight: 1000kg

- Workers needed: 1~2

- Plant: 30~50 square meters

- Business type: Manufacturer

- Accepted Delivery Terms: FOB, CFR, CIF, EXW

- Guarantee: 1 Year

- Item: Cooking oil press

- Suitable objects: Palm , Palm etc.

- Manufacturing experience: 30+ years

The influences of various reaction parameters on the conversion of palm oil to biodiesel were performed, and the orthogonal test was investigated to seek the optimum reaction conditions, which were illustrated as follows: methanol to oil mole ratio of 24:1, catalyst dosage of 3.0 wt% of oil, reaction temperature of 120 °C, reaction time of 150.

Several parts including the type of catalyst, oil/alcohol ratio, temperature, stirring speed and free fatty acids content, have been found to influence the transesterification of palm oil. Optimum reaction conditions were obtained with a molar ratio of methanol-to-oil at 10:1 and a reaction time of 7 min at ca. 65?C.

Transesterification of Palm Oil for the Production of Biodiesel

- Usage: Palm Oil

- Type: Reasonable Price Hot Sale Oil Press Palm Oil Press Machine

- Production Capacity: 98%-100%

- Voltage: 220v

- Dimension(L*W*H): 500*300*700mm

- Weight: 70 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Provided

- Video outgoing-inspection: Not Available

- Warranty of core components: 1 Year

- Core Components: Other

- Raw material: Palm Kernel

- Advantage: Energy Saving, very long service life

- Capacity: 2-4kg/h

- Keep working: More than 12 hours

- Material: stainless steel 304

- Color: red, blue, or customization

- Heater: Optional

- Package size: 0.2 CBM

- Delivery time: 6 days after payment

- Application: Making Palm Oil with Seeds

The PzOH/SiO2 catalyst exhibited high activity in the transesterification of palm, corn, grape seed, and Palm oils (S-oil) with methanol, achieving ~90% conversion at 75°C with a catalyst.

The study was evaluated by five levels of methanol-to-oil ratio (1:1 12:1), catalyst (0.1- 2%) and reaction time (30 150 min).The optimum process variables for transesterification of palm.

Two-stage reaction rates in transesterification of Palm Oil Production Line

- Usage: Palm oil extracted machine

- Type: Palm oil extracted machine

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Power(W): 18.5KW/T

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- After-sales Service Provided: Overseas service center available

- Keywords: oil press machine

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: Palm oil extracted machine

- oil rate: 20%-98%

Transesterification of refined palm oil and methanol with IRA402 and A26 anion-exchange resins as heterogeneous catalysts was conducted. THF was added as a co-solvent to improve the miscibility of oil and methanol. IRA402 was used to study the reaction rates occurring in the approximate absence of pore diffusion and external mass transfer.

The aim of the project is to make biodiesel from palm oil by Transesterification reaction. The acid value of palm oil was found to be 0.957 which enabled direct alkaline transesterification. The optimum catalyst concentration and alcohol concentration required for maximum yield were found as 2.5 wt% and 40 wt% of oil respectively.

Optimization of the Transesterification Process of Palm Oil Production Line

- Usage: Palm Oil

- Production Capacity: 98%

- Voltage: 380V/50HZ

- Dimension(L*W*H): 1290*460*960MM

- Weight: 180 KG

- Warranty: 1 Year

- Key Selling Points: Famous brand motor

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Raw material: Palm Kernel

- Function: Press Oil Seeds

- Application: Oil Production Line

- Material: Stainess Steel

- Feature: Eco-Friendly

- Oil rate: Oil Yield 98%

- Output: 10-20T/DAY

in the transesterification reaction are: the alcohol / oil molar ratio, the amount of catalyst and the temperature, its effect being evaluated by kinetic studies and few using statistical designs. The alcohol / oil molar ratio varies from 0.1: 1 24: 1. The concentration of the catalyst varies from 0.25% 6% by weight regarding to the oil. The

Supercritical Transesterification of Palm Oil and Hydrated

- Usage: Palm OIL

- Type: Automatic Palm Fruit Oil Processing Machine

- Warranty: 3 months

- Key Selling Points: Long Service Life

- Marketing Type: Ordinary Product

- Machinery Test Report: Not Available

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Other

- After-sales Service Provided: Online Support, Video technical support, Online support

- Local Service Location: None

Biodiesel production from palm oil and hydrated ethanol in a fixed bed reactor using CaO/Al2O3 as the catalyst was investigated and optimized using response surface methodology. The investigated parameters were temperature, pressure, ethanol/palm oil molar ratio, residence time and total mass flow rate. The approach was divided into two parts, a preliminary study using broad scale changes over.

- Can oleic acid infused palm oil facilitate biodiesel production via transesterification?

- A novel catalyst utilizing CaO derived from blast furnace dust waste has been developed to facilitate biodiesel production via transesterification. In this study, oleic acid-infused palm oil was used to simulate acid oil, and the resulting biodiesel met ASTM D 6751 standards.

- What is RSM based biodiesel production from palm oil?

- Current study presents RSM based optimized production of biodiesel from palm oil using chemical and enzymatic transesterification. The emission behavior of biodiesel and its blends, namely, POB-5, POB-20, POB-40, POB-50, POB-80, and POB-100 was examined using diesel engine (equipped with tube well).

- Can palm oil be used as a feedstock for biodiesel production?

- Although palm oil is in use as a feedstock for biodiesel production, no earlier studies are reported on the RSM based simultaneous optimization of chemical and enzymatic transesterification for production of biodiesel using palm oil.

- Can palm oil sludge be transesterified to produce biodiesel?

- Following esterification, transesterification of the esterified palm oil sludge produced biodiesel with an 83.72% yield. The optimized conditions for this process included a methanol-to-palm oil sludge molar ratio of 10:1, a reaction temperature of 60℃, and a reaction time of 1 h .

- Does ethanol facilitate the transesterification of kernel palm oil?

- Ethanol not only facilitates the transesterification process but also enhances the fuel properties of the biodiesel , . Table 15. Efficiency of Different Catalysts in the Transesterification of Kernel Palm Oil. Clay crystallinity significantly increases after modification.

- How to produce biodiesel from palm oil?

- Depletion of petroleum had captured much attention on producing biodiesel from the palm oil. Approach: The most concerning methods for the production of biodiesel were discussed, namely transesterification (alkali and acid), enzymetic approach and supercritical alcohol.