Palm oil mill process flow diagram introduction

- Usage: Palm Oil

- Type: Palm oil refinery plant process

- Production Capacity: 80kg/h, 500kg/h, 100kg/h

- Voltage: 380V/440V

- Power(W): Depend on the Palm oil refinery plant capacity

- Dimension(L*W*H): Depend on the Palm oil refinery plant capacity

- Weight: Depend on the Palm oil refinery plant capacity

- product name: 300TPD Palm oil refinery plant/Palm oil refining process

- Key word: Palm oil refinery plant

- Color: As your requirement

- Materials of the equipment: stainless steel and carbon steel

- Distillation range: 68-75℃

- Solvent residual after desolventizer: <300ppm

- Deodorization loss consumption: ≤0.5%

- Refining method: phisical or chemical as your requirement

- Warrenty: 12months

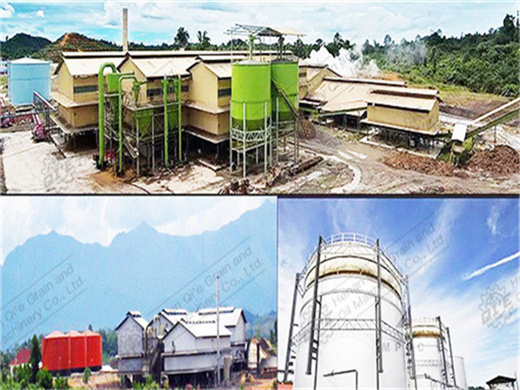

The entire palm oil mill process involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export. Palm oil mill process flow diagram (click here.

Complete palm oil production process in a large-scale palm oil factory. Fresh fruit bunches (FFB) of oil palm after the fruit is harvested, it is processed in a palm oil mill, where the FFB is sterilized, digested, and pressed to extract palm oil. The extracted oil is then clarified and sent to a crude palm oil refinery plant, or fractionation.

Palm Oil Mill Palm Oil Production Line Palm Oil Refinery Machine

- Usage: Palm Oil

- Production Capacity: 5-6Ton/Day

- Voltage: 380v/50hz/3p

- Dimension(L*W*H): 4250x1400x2000mm

- Weight: 10500 KG

- Warranty: 1 Year

- Key Selling Points: High productivity

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pump, Gear, Gearbox

- Raw material: Palm Kernel

- Working pressure: 60Mpa

- Product oil: cold oil

- Advantage: High productivity

- Color: Clients' Requirements

- Used for: Palm Oil Making

- Machinery type: Single Oil Making Machine

- warranty period: 5 years

Palm Oil Mill process is quite different from other vegetable oil seeds processing. Palm fruits consists a lot of fatty acid enzyme, which would hydrolyze palm oil. That’s the reason why palm fruit must be sent into processing in 24 hours. At the Palm oil mill, the main products that are produced from FFB to Crude Palm Oil (CPO) and Palm Kernels.

The following is 15-120tph large scale palm oil mill process flow diagram. Palm oil mill process flow diagram. Process flow diagram for palm oil production. The entire palm oil mill process involves the reception of fresh fruit bunches from the plantations. Then the palm fruit bunches will be sent to palm fruit sterilization station.

Crude Palm Oil Processing Sanpya Engineering Alliance Co., Ltd

- Usage: PALM Oil

- Production Capacity: 15 tpd

- Voltage: 50 HP

- Dimension(L*W*H): 2640MM*1396MM*3403MM

- Weight: 7000 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 5 years

- Core Components: Motor, Gear, Bearing, Gearbox

- After-sales Service Provided: Engineers available to service machinery overseas

- Extraction of Oilseeds: PALM KERNEL

- MOTOR: 50 HP

- CAPACITY: 15 Tons/Day

The oil is obtained from the fruit of the oil palm, which finds optimum growing conditions in tropical countries with a constant climate. The oil is processed throughout the year in non-stop operations. The machines and process lines must be correspondingly resistant and robust. GEA supports all procedures and processes for recovering palm oil.

Palm oil mill process includes 6 parts: Palm fruits receiving, sterilizing, threshing, digesting and pressing, crude oil clarifying and palm kernel recovery. SterilizationThe main purpose of sterilization is to destroy the lipase in the pulp, so as to prevent the free fatty acid content in the oil from increasing. We offer both horizontal and vertical […]

Palm Oil Processing Production Line Palm Kernel Oil Press Machine

- Usage: Palm Oil

- Production Capacity: 40-50%

- Voltage: 220V

- Dimension(L*W*H): 45*18*30cm

- Weight: 42.5 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Product name: Tanzania Palm oil making machine extraction Palm oil machine

- Product Product function: extraction oil from Palm

- Power: 1.6kw

- Processing: 13 (kg/h)

- Squeezer diameter: 27 (mm)

- Squeezer speed: 80 (r/min)

- spiral: 30 to 60 (%)

- The power supply voltage: 110/220 (V)

- Dry cake residual oil percentage: 5 (%)

For small-scale palm processing farmers, HongDe Machine has designed single-screw and double-screw palm fruit oil press, which can process 1ton, 5 tons, 10 tons and 15 tons of palm fruit per hour. Reliable palm oil press machine with simple operation, gaining a good reputation in Africa and South America.

Palm Oil Production Process: A Step-by-Step Guide

- Usage: Palm oil extracting machine

- Production Capacity: 100kg/h, 500kg/h, 1tph, 5tph, 10tph

- Voltage: 220V/380V/400V

- Power(W): according to the different models

- Dimension(L*W*H): according to the different models

- Weight: according to the different models

- specifications: Palm oil extracting machine

- capacity: 0-3000TPD

- certificate: ISO&BV&CE

- remark: turnkey project

Digesting Process-Palm Oil Digester Machine & Palm Fruit Digester Machine Complete Palm Oil Production Process Design-Each Process Palm oil production is a complex process that involves a variety of stages, each of which is critical to the success of the overall operation.