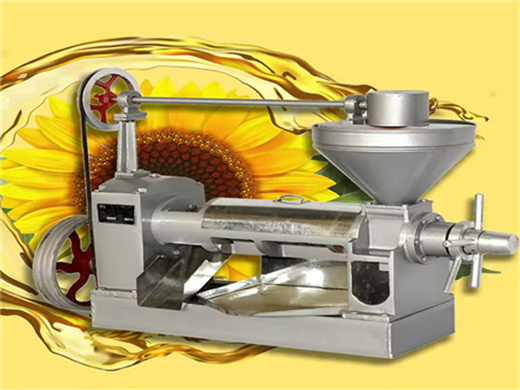

Cooking Oil Refinery Machine Cooking Oil Processing Plant

- Usage:

- Type: Cooking Oil Refinery Machine

- Production Capacity: 5T~880T/D

- Voltage: 380V

- Power(W): <25KWh/T

- Dimension(L*W*H): according to capacity

- Weight: depending on the capacity

- Material: stainless steel and carton steel

- Steam consumption: <280KG/T (0.8MPa)

- Business type: manufacturer

- Crude oil moisture and volatile matter: <0.3%

- Item: Cooking oil extraction machinery

- Raw material: various seeds

Consider both current and future needs to ensure that the refinery machine can handle your desired output. 2. Refining process: Understand the refining process employed by the machine. Different machines may use different methods such as chemical refining, physical refining, or a combination of both.

Cost of Setting up an Oil Mill in India. For starting a groundnut oil mill plant setup cost can vary greatly depending on several factors, including the size and scale of the operation, the location, the type of equipment and machinery used, and more.A small-scale groundnut oil production plant may cost anywhere between 7,00,000? and 25,00,0000?, while a large-scale operation can cost

Palm Oil Refinery At Best Price In India

- Condition: New, new oil refinery equipment

- Usage: Cooking...., BV, ISO9001, CE, etc. for alibaba oil refinery equipment

- Product name: Cooking oil refining machine

- Color: depend on requirements for oil refinery equipment

- Electric consumption: 28kwh/T oil

- Use: use oil refinery equipment to refine oil

- Capacity: based on requirements for oil refinery equipment

- Steam consumption: 450kg/T oil

- Deodorization loss consumption: ≤0.5%

- Bleaching earth consumption: 5~50Kg/Toil

Find here online price details of companies selling Palm Oil Refinery. Get info of suppliers, manufacturers, exporters, traders of Palm Oil Refinery for buying in India.

Brissun Technologies Pvt Ltd is a globally established engineering & manufacturing organization with expertise in Oil Refineries Plant, Edible oil mill refinery & extraction plants manufacturers, supplier & Exporter From India

Good Price Sunflower Oil Refinery Machine In Turkey

- Usage: oil refinery

- Type: Cooking oil refinery

- Production Capacity: 10-1000TPD, 10-700TPDcrude oil refinery machine

- Voltage: 380

- Power(W): according the capacity of refining

- Dimension(L*W*H): according the capacity of refining

- Weight: different

- Phosphoric acid: 2~3 kg/T oil

- Waste bleaching earth oil content: 5% to 15 %

- soften water: 150Kg/T oil

- Refining rate: refining consumption 1%

- Bleaching earth consumption: 3-5Kg/Toil

- Circulating water cooling water yield: 150M3/H

- Steam consumption: 450kg/T oil

- application: refinery crude oil

Sunflower Oil Mill Refinery Process Flow. Process Description : 1. Degumming of Sunflower oil refinery machine The purpose of degumming is to remove impurities such as phospholipids, gums and proteins etc. There are several methods as follows: water degumming, acid degumming, special degumming etc. 2. Neutralizing of sunflower oil refinery machine

Oils Fats Refining Equipment and Turnkey Plants. We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

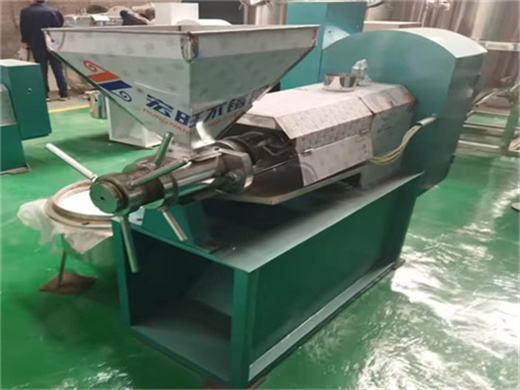

Cost Of Small Scale Cooking Oil Making Machines

- Type: Cooking oil refinies

- Use: Cooking oil refinies

- Solvent: hexane

- Material: stainless steel

- Product name: Cooking oil refinies

- Price: Negotiation

- Packaging: wooden cases

- Trade term: EXW,FOB,CFR.CIF

- Oil residue ratio: 0.5-1%

- Power consumption: ≤ 15KWh/T

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Solvent consumption: ≤ 2Kg/T (No.6 solvent oil)

QIYI Machinery sets of small scale cooking oil unit equipment won the national patent (patent number: ZL 99 252888.7), is currently developing the third generation of our edible oil making machine.Our small scale oil refinery plant are great choice for small capacity oil refinery machine.The small scale oil refinery production plant can

Setup Small Oil Mill Plant, How To Do Cost Estimation

- Usage: 5 ton Cooking oil refinery

- Type: 5 ton Cooking oil refinery

- Production Capacity: 10T-3000T/D

- Voltage: 220v / 380v or local voltage

- Power(W): Depend on 5 ton Cooking oil refinery capacity

- Dimension(L*W*H): Depend on 5 ton Cooking oil refinery capacity

- Weight: Depend on 5 ton Cooking oil refinery capacity

- Product name: 5 ton Cooking oil refinery

- Electric Consumption: Depend on 5 ton Cooking oil refinery capacity

- Handling capacity: Depend on 5 ton Cooking oil refinery capacity

- Advantage: High efficiency

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Export markets: All over the world

- Delivery time: 25-45 Days

- Machine color: Depend on customers' request

- Supplier Type: Manufacturer

- Suitable for: Cooking and other plants seed

20TPD Palm Kernel Oil Refinery & Fractionation Machine Setup in Nigeria 15TPD Sunflower Oil Manufacturing Plant Setup in Uzbekistan 50TPD Corn Oil Extraction Plant and 15TPD Oil Refinery Line in Iran Small Soybean Oil Production Machine & Plant Installed in Nigeria >20TPD Oil Refinery Plant Project

- What is sunflower oil refinery plant?

- Sunflower Oil Refinery Plant is a machinery setup manufactured and developed to refine the crude sunflower oil with the key step of elimination of impurities from that crude oil. We at Tinytech Udyog offer small scale to medium scale Sunflower Oil Refinery Plants on Turnkey basis.

- What is a batch type sunflower oil refinery plant?

- Our Batch Type Sunflower Oil Refinery Plant will give High-Quality Refined Sunflower Oil as Output. Neutralization Reactor: For acid refining, alkali refining and water washing. Decolorization Reactor: To Bleach the Oil and remove pigment from oil. Deodorization Reactor: Removes odor from oil.

- How sunflower oil refining is successful?

- Sunflower Oil Refining becomes successful with the help of series of treatment processing being made through equipments in controlled conditions. Every refinery equipment leads to betterment in the oil quality. Clients can convert crude sunflower oil into refined sunflower oil on Tinytech Sunflower Oil Refinery Plant full of technology.

- Why should you refine sunflower oil on tinytech refinery machine?

- Refining the crude sunflower oil on our Tinytech refinery machine will eventually produce an additive free product having good oxidative, flavor and cold-test stabilities. Idea about our Sunflower Oil Refinery can be obtained by going through the below pictures.

- How does sunflower oil remove turbidity?

- Sunflower Oil presents an un-pleasant turbidity at low temperature. This can be removed by eliminating components like waxes which solidify at low temperature through the process known as Dewaxing. The process of dewaxing is carried out especially for Sunflower Oil to remove those waxes.

- How to make sunflower oil edible?

- The extracted sunflower oil should be processed further to make it an edible product. Edible oils are refined to improve their flavor, odor, color and stability. The refining process will remove contaminants such as phosphatides, free fatty acids and pro-oxidants. Apart from the normal refining steps, some oils and fats need further processing.