Cost Of Setting Up A Rice Bran Oil Refinery Plant

- Usage: Cooking Oil

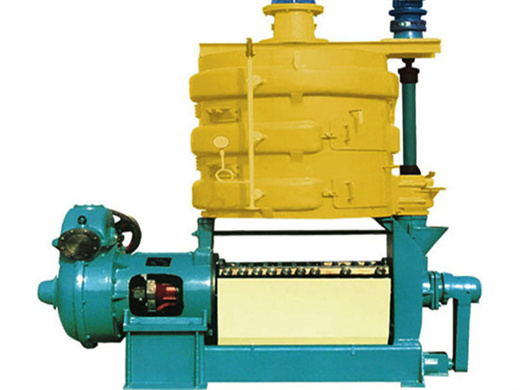

- Type: Cooking Oil Refinery Machine, mill machine

- Automatic Grade: Automatic, Full/semi Automatic

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 70-150kw

- Dimension(L*W*H): Depend on capacity

- Weight: Depend on capacity

- Dimension: standard

- Capacity: 10 ~2000T/D

- Main Material: Carbon Steel /stainless steel

- Color: As your demand

- Certificate: CE&ISO9001

- Quality Control: X-ray Detection

- Warranty Period: One Year

Henan Glory Company has been engaged in rice bran oil refinery for more than ten years and we have helped many India customers install the rice bran oil refinery plant . Besides that, the oil refined by our rice bran oil refinery machine has long storage time and can meet the high quality and high standard requirements of edible rice bran oil.

We are the leading players in managing end-to-end operations for leadin national and multi-national companies in India. Our customers can finally focus on their core areas, while fully entrusting us to manufacture, pack and ship the various SKU’s as per their requirements and quality standards.

Rice Bran Processing Plant Ferro Oiltek Pvt. Ltd

- Usage: Mini edible oil refinery

- Type: Cooking Oil Refinery Machine

- Production Capacity: 100% Mini edible oil refinery

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity

- Weight: Depand on your capacity

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Application: cooking oil refining

- Common capacity: 1-1000TPD

- Character: semi-continuous,fully continuous

- Certificate: CE/BV/ISO9001

- Advantage: high oil yield

- Material: stainless steel/carbon stell

Rice bran Oil is on hot sale in recent years and was recommended to be one of the best and healthier cooking oil and frying oil. It is praised for being versatile and having a neutral taste and stable when exposed to high temperatures.

After cleaning, the rice bran is conditioned to prepare it extraction. This involves adjusting the moisture content and temperature of the bran to achieve the ideal conditions release. Proper conditioning enhances the efficiency of the rice bran oil refinery process by ensuring the bran is at its optimum state for extraction. 3.

Rice Bran Oil Processing Plant

- Usage: Cooking oil refinery equipment

- Type: Cooking Oil Refinery Machine

- Production Capacity: 30T~100T/D

- Voltage: 220V/380V

- Power(W): 28KWh/T

- Dimension(L*W*H): according to capacity

- Brand: Qi'e

- Steam consumption: <280KG/T (0.8MPa)

- Business type: manufacturer

- Crude oil moisture and volatile matter: <0.3%

- Item: Cooking oil refinery equipment

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Operating pressure: normal/negative pressure

- Dimension: depend on capacity

rice bran oil processing plant includes rice bran pretreatment & extrusion workshop, oil solvent extraction plant and Oil Refinery Plant. Hua County Henan Province, China +8615937289608 [email protected]

However, the crude rice bran oil can’t eat and sell to the market. The crude rice bran oil must be processed with rice bran oil refinery plant. Rice bran Oil Refinery Plant can remove unhealthy impurities such as phosphatides, free fatty acids (FFA), pigments, off-flavor, etc. After refining, the flavor, color and smell of rice bran oil is

Rice Bran Solvent Extraction Plant At Best Price In India

- Type: crude oil refining machine

- Use: crude oil refining

- Product type: crude cooking oil refining machine

- Steam consumption: 450kg/T oil

- Phosphoric acid: 2~3kg/T oil

- Electric consumption: 28kwh/T oil

- Bleaching earth consumption: 5~50Kg/Toil

- Waste bleaching earth oil content: <35%

- Deodorization loss consumption: ≤0.5%

- Certificate: ISO9001, BV, CE

- Outstanding: low price,fast return

- Color: based on requirements for first class oil refinery equipment

Spectec solvent extraction plant, capacity: 50-200 tpd; Standard rice bran oil refinery equipment, >20, capacity: 50 Rice bran solvent extraction plant; Spectec ss,ms oil solvent extraction plant, capacity: 50-200 Rice bran oil manufacturing plant; Solvent extraction plant, capacity: 50 tons/day; Mild steel solvent extraction plants

Standard Rice Bran Oil Refinery Equipment, ≫20, Capacity: 50 ..

- Usage: Cooking

- Type: Cooking Oil Refinery Machine

- Production Capacity: 100%

- Voltage: 220v/380v or local voltage

- Power(W): Low energy, According to the different capacity

- Dimension(L*W*H): According to the different capacity

- Weight: According to the different capacity

- After-sales Service Provided: Overseas service center available

- Warranty: 3 Years

- Application range: Plant Seed,stem,foliage

- texture: SS or CS

- Color: According to the requirements of clients

DVC Process Technologists Offering Standard Rice Bran Oil Refinery Equipment, >20, Capacity: 50-1000 Tonnes Per Day at Rs 60000000 in Jejuri, Maharashtra. Also find Vegetable Oil Refinery Plant price list ID: 18985056688

- What is rice bran oil factory?

- Rice bran is the main by-product of rice processing mill. Per 100kg rice can produce about 5-8kg rice bran. It is also a common kind of oil-bearing material. With the development of rice processing industry and oil extraction technology, setup rice bran oil factory is becoming a HOT project with great commercial value to invest in.

- How much oil does Afghanistan have?

- Currently private sector refineries have the capacity to refine half of total oil supply of Afghanistan, with combined capacity of 32,500 barrels per day. Afghanistan has estimated reserves of 1,908 million barrels of crude oil + 59 trillion cm of natural gas + 667 million barrels of liquid gas.

- What is the capacity of rice bran oil pressing unit?

- This is a small rice bran oil pressing factory build in Thailand. The capacity of this small oil pressing unit is 5 Tones per Day (5TPD). Rice Bran Oil is a material that can be found in the outer layerlskin of a paddy seed, that can be obtained from screw pressing,milling or solvent extraction.

- How many oil & gas companies are there in Afghanistan?

- There are about 35 companies that dominate the importing and distribution of oil and gas In term of storage, both government and private sector have storage capacity of 415,752 MTs located throughout Afghanistan: This includes FLGE capacity of 238,023 MTs + MoD/MoI capacity of 23,888 MTs + private storage capacity of 153,841 MTs.

- What is the refining process in Afghanistan?

- The refining process takes place in two phases. The first processed crude is discarded as industrial waste. As Afghanistan’s economy continues its transition to a mature post-war phase, Kam International Oil is committed to the development of the nation’s energy sector.

- How can Afghanistan reduce its dependence on energy imports?

- Continue increasing refinement capacity to further the goal of reducing – and ultimately eliminating – Afghanistan’s dependence on Energy imports. After decades of conflict, Afghanistan needs to re-build its technical capacity to efficiently process oil.