Afghanistan Vegetable Oil Refinery Plant Oil Refinery Machine

- Usage: Cooking oil refining facility

- Type: Cooking oil refining facility

- Production Capacity: 5T~10T/D

- Voltage: 220V/380V

- Power(W): according to capacity

- Dimension(L*W*H): depend on capacity

- Weight: according to capacity

- Item: Cooking oil refining facility

- Application: various crude oil like Cooking oil, seLDe oil

- Operating ways: safe and simple

- Residual oil in cake: low

- Oil grade: high

- Cultivation Type: organic

- Processing Type: refined

- Refining technics: batch refining, semi-continuous refining

- Moisture and volatile: 0.08%

To secure Afghanistan’s long-term energy independence, Afghanistan needs to increase upstream oil production and build refining capacity Currently Afghanistan has refinery capacity of 32,500 barrels per day. However, the refineries produce very low quality oil and they are generally inefficient in their production. Therefore, Afghanistan

The proposed manual describes the basics of designing refineries and petrochemical plants. The manual has been compiled in accordance with the curriculum of the course “Designing of oil refining

Ghazanfar Oil Refinery Ghazanfar Group Refinery

- Type: Cooking oil refinery equipment

- Use: Cooking oil refinery equipment

- Product name: Cooking oil refinery equipment

- Production Capacity: 10-3000TPD

- Voltage: 220V/380V

- Power(W): According to your Capacity

- Dimension(L*W*H): depend on the mode

- Weight: depend on the mode

- Item: Cooking oil refinery equipment

- Water content in press cake: 40%

- Oil extract rate: 21-23%

We govern our group using the values and virtues passed down on us through the decades by our elders

The explanation begins with the history of crude petroleum oil and where it generated, how people first get crude petroleum oil traditionally, how it generally shifted into two major part : (1) Upstream Process and (2) Downstream Process and how it was developed through centuries to become a modern plant in many places around the world.

Oil &Amp; Gas Ghazanfar Group

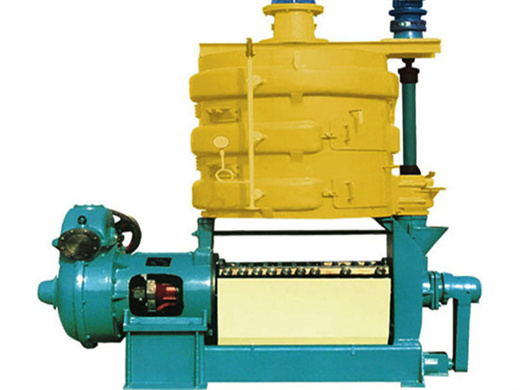

- Usage: Cooking Oil extraction machine with refinery

- Type: Cooking oil extraction machine with refinery

- Production Capacity: 10-300T/D

- Voltage: 220v,380v,or other

- Power(W): different

- Dimension(L*W*H): according to the capatiy

- Weight: according to the capatity

- Color: According to customer requirements

- oil content: 35%-48%

- pressing residual oil: less than 7%

- sovent residual oil: less than 2%

- oil purpose: cooking oil

- brand: zhengzhou qie

- oilringal: China

- sales: many country

We govern our group using the values and virtues passed down on us through the decades by our elders

Cracking oil refinery, heavier oil conversion; Full conversion or deep conversion, maximum conversion. Lube Oil Refinery; Petrochemical Oil Refinery; 1. Topping Oil Refinery. A topping refinery is the simplest refinery configuration that is designed to produce feedstock for petrochemical manufacturing plants or for the production of industrial

Oil Refinery Plant Worth $1.3 Billion To Be Built In Northern ..

- Usage: all kinds of vegetable oil

- Type: Cooking Oil Refinery Machine

- Automatic Grade: Semi-Automatic

- Production Capacity: depends on the capacity

- Voltage: 380 voltage

- Power(W): according to capacity

- Dimension(L*W*H): depends on the capacity

- Weight: according to the capacity

- color: white

- capacity: 1-100t

- power: 32kw

- size: according to the capacity

- function: refine kinds of vehetable oil

- oil quality: clear, transparent, odorless

- production time: 30 days

- service: arrange technicians to factory of user for instruction

- payment terms: negotianable

The construction of an oil refinery plant worth USD 1.3 billion will be built in northern Jawzjan province of Afghanistan. Ahmad Rateb Popal, chief of Watan Group told reporters on Wednesday that the oil refinery plant will be built in Sheberghan city of Jawzjan province.

Refinery Plant Design Vista Projects

- Usage: Camelia Oil Refining Equipment

- Type: Cooking Oil Refinery Machine, Camelia Oil Refining Equipment

- Production Capacity: 50TPD Camelia Oil Refining Equipment

- Voltage: 380V

- Cooking Oil Machinery Process: Pre-treatment,Solvent Extraction,Refining

- Material: Stainless and Carbonless Steel

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Pretreatment Process: Cleaning,Hulling,Breaking,Soften,Flaking,Puffing,Toasting

- Solvent Extraction Process: DTDC,Miscella Toasting and Stripping,Solvent Collecting,etc

- Refining Process: Degumming,Deacidification,Deordorization,Decoloration,etc

- Process Capacity: 50TPD

- Service: Engineer Abroad Erection

- Packing: Frame and Container

Vista Projects performed the detailed engineering design of an asphalt storage facility with transfer stations. The facility included: two 64,000 barrel asphalt storage tanks; four truck off-load and two truck load-out stations; associated pumps and piping systems; The design also included a hot oil heating system for tank heating and heat tracing.

- How many tons a day does Ghazanfar oil refinery produce?

- Ghazanfar Oil Refinery has an operating capacity of 500 metric tons per day or 150,000 metric tons per year. Using low sulfur crude, oil distillates and other oil derivatives, the refinery and processing units will produce petrol A-80, Kerosene, Diesel and Mazut.

- How much oil does Afghanistan import per day?

- Currently Afghanistan has refinery capacity of 32,500 barrels per day. However, the refineries produce very low quality oil and they are generally inefficient in their production. Therefore, Afghanistan crude oil imports all its oil as finished refined products

- Where is Ghazanfar oil refinery located?

- The Ghazanfar Oil Refinery is located in Hairaton City in Northern Afghanistan. Our refinery is situated by the Ghazanfar Dry Port and near the main rail with railway transportation networks into Central Asia and trucking networks reaching throughout Afghanistan.

- What types of petrol will be produced by the refinery & processing units?

- Using low sulfur crude, oil distillates and other oil derivatives, the refinery and processing units will produce petrol A-80, Kerosene, Diesel and Mazut. Through additional processes, we will be producing winterized diesel and high octane petrol.

- How many oil & gas companies are there in Afghanistan?

- There are about 35 companies that dominate the importing and distribution of oil and gas In term of storage, both government and private sector have storage capacity of 415,752 MTs located throughout Afghanistan: This includes FLGE capacity of 238,023 MTs + MoD/MoI capacity of 23,888 MTs + private storage capacity of 153,841 MTs.

- Is flgE a profitable business in Afghanistan?

- We therefore recommend the formation of the Afghan Petroleum and Gas Authority to oversee the industry Afghanistan’s national oil state-owned enterprise FLGE is currently a profitable business. The company generates $4.5 million (1393) in revenue. The company owns 238,023 MTs of oil and gas capacity and 94 trucks.