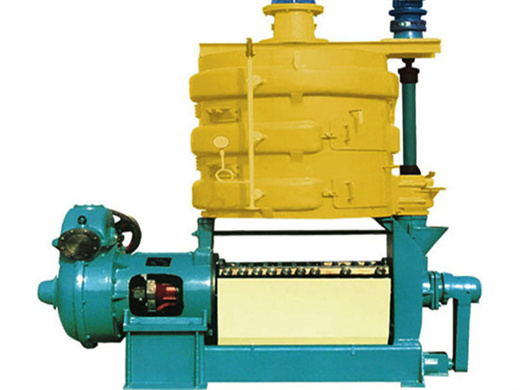

40Tpd Soybean Processing Plant Installed In Zambia Oil Expeller And Oil Refinery Machine

- Usage: edible oil refining machine

- Type: Cooking Oil Refinery Machine

- Production Capacity: 98%

- Voltage: 380V/50HZ

- Power(W): 2.1KW

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 20000KG

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Material: Stainless Steel SS304/316

- Advantage: Energy Saving

- Use for: edible oil refining machine

- Application range: Kinds Seeds

- Warranty: 12 Months

- Feature: Eco-Friendly

- Color: Blue

- Section: Oil Refinery Machine Section

- Quality: Super High

40 Ton Per Day Soybean Processing Line is installed on Turnkey Basis in Zambia. A complete soya bean processing plant includes various processes such as soybean cleaning, soybean destoning, soybean cracking, hulls separations, soybean extrusion, oil pressing, crude oil filtration, cake cooling and cake bagging section.

BEST solutions for soybean oil mill line, offered by Goyum Screw Press a leading manufacturer and exporter of oil production & oil refining plants and related oil equipment. Timely delivery, high quality, competitive price. Soybean Oil Processing Plant Project Running Video

Soybean Oilseeds, Oil &Amp; Meal: Processing, Uses &Amp; Specifications

- Usage: Oil Refining

- Type: Oil Refining

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 10-50kw

- Dimension(L*W*H): According to the capacity

- Weight: According to the capacity

- Item: Sophisticated Technology Cooking Oil Refinery Plant

- Voltatile substance in crude oil: ≤0.3%

- Clay consumption: depending on color of crude oil

- Solvent contain in crude oil: ≤200ppm

- Oil residue in waste clay: ≤25% of waste clay

- Performance: Excellent

- Steam pressure: ≥1.2MPa

- Steam consumption in refining: ≤280kg/ton

- Warranty: 12 Months, long term technical support

- Feature: High Output

Soybean (also known as soyabean), the legume or bean with the botanical name Glycine max, has attained global importance as a rich source of proteins and polyunsaturated oil after the World War II. It is also an important vegetarian source of omega-3 and omega-6 fatty acids. Direct food uses of soybeans include soya milk and tofu (made from soya milk). Fermented foods like soy sauce are also

Bleaching. This is one the important stage in total refining process. Where the oil is heated to 100°C to 105°C and mixed with Bleaching earth chemical ( Acid Activated Clay) and also activated carbon in a vessel under vacuum at 70 mmHg where the stirring continues for specific designated time and then filtered the oil to remove the clay and carbon.

Soybean Oil Refinery Process Pemac Projects Pvt Ltd

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 5-100TPD

- Voltage: 230V-380V-430V

- Power(W): 40kw/h

- Dimension(L*W*H): 20m*16m*15m

- Weight: 30tons

- After-sales Service Provided: Overseas third-party support available

- Machine type: Cooking Oil Refinery Process Flow

- Machine application: Cooking oil

- Operation time: 24hours

- Electrical control: PLC control

- Workers needed: 2-3persons

- Machine material: carbon steel or stainless steel

- Power consumption: 22KWH/T oil

- Steam consumption: less than 300kg/t oil

- Soft water consumption: about 160kg/h

- Warranty period: 1year

Soybean oil is a major vegetable oil that is used in a variety of food products, as well as in industrial applications. The soybean oil refinery process is used to remove impurities from crude soybean oil, making it safe for human consumption and suitable for industrial use. The soybean oil refinery process typically consists of the following

sunflower oil refinery plant high capacity in afghanistan Machine Type: sunflower oil refinery plant; Production Capacity: 2500Kg/day; Dimension(L*W*H): 2020*1315*1570; Power: 5.5-22kw; Palm Oil Machinery with Good After-Sale Service; Speed of Squeezing Worms(R/Min): 60; Raw Material: sunflower; Market: afghanistan

Soybean Oil Refining Process Unveiled Expert Guide

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine, Cooking Oil Refining Machine

- Production Capacity: 150TPD Cooking Oil Refining Machine

- Voltage: 380V

- Power(W): Based on Cooking Oil Refining Machine capacity

- Dimension(L*W*H): Based on Cooking Oil Refining Machine capacity

- Weight: Based on Cooking Oil Refining Machine capacity

- Processing capacity: 150TPD Cooking Oil Refining Machine

- Material: Stainless,carbonless steel

- Raw Material: Cooking,Cooking,Cooking,etc

Complete Soybean Oil Production Plant Layout. The refining of soybean oil, a process that removes impurities and enhances its stability, is a crucial step in ensuring the oil's superior quality. With its demand steadily increasing across industries, the market for soybean oil and its refined products is poised for further growth.

10Tpd Cottonseed Oil Refinery Production Line In Afghanistan

- Usage: Tallow oil

- Type: Refinery production line

- Automatic Grade: Semi-Automatic

- Production Capacity: 30-60TPD

- Voltage: 380V/3 phase

- Power(W): According to your capacity

- Dimension(L*W*H): According to your capacity

- Weight: According to your capacity

- Supplier type: Manufacturer

- Manufacturing experience: 19 years

- Texture: Mild steel and SS

- Capacity: 30-60 TPD

- Function: Deacidification and deodorization

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Production cycle: 65 days

- Installation period: 60 days

Through continuous communication and confirmation, he was pleased with the production plan we suggested. In the end, he purchased a 10TPD cotton seed oil refinery and fractionation line and packing and filling machine to equip his cottonseed oil pressing plant into a complete cottonseed oil production plant which includes cottonseed oil pressing, cottonseed oil refining and cottonseed oil

- How to set up a soybean oil mill plant?

- Here we have listed some of the basic machinery required to set up Soybean Oil Mill Plant Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration.

- How much does a soybean oil refinery cost?

- The comparable operating expenses for a soybean oil refinery will average about $39.70 U. S. per metric ton of refined product ($35.30 to $48.50 range) with an incremental $22.00 U.S per metric ton for hydrogenated products ($17.60 to $38.50 range).

- How much does a greenfield soybean oil refinery cost?

- Likewise, for a greenfield soybean oil refinery, the capital requirements will average about $45,900 U.S. per metric ton of daily refining capacity. The capital range would be from $33,000 to $55,000 per metric ton of daily capacity for a consolidated refining/bleaching/hydrogenation/deodorization facility.

- Which countries produce soybean oil in the world?

- The major Soybean producing countries in the world are USA, Brazil, Argentina, China, India, Uruguay, Ukraine, Bolivia, Nigeria, South Africa Complete Turnkey 60 TPD Soybean Oil Mill Installed in Ethiopia Feel free to inquire for detailed information about soya bean oil extraction plant and soybean oil mill machinery.

- What are the advantages of soybean extruder technology?

- Advantages of Extruder Technology: Soybean obtained after the preparatory process can be used as a raw material for Soybean Oil Extraction. The soybean contains 18 – 20 % oil content. After a single stage pressing, about 5 – 5.50% residual oil in the soybean meal which will be used in animal & poultry feed.

- What is the process of soybean oil extraction plant?

- Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.