List Of Oil Refineries In India

- Usage: Cooking

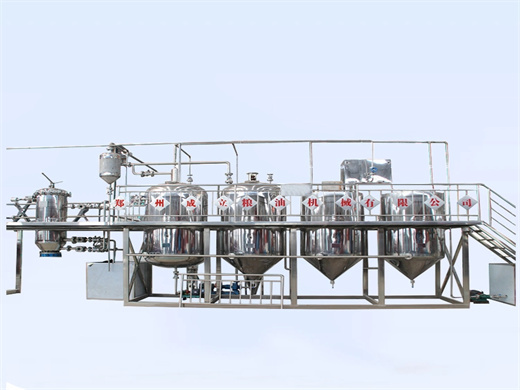

- Type: Cooking Oil Refinery Machine

- Production Capacity: 1-100TPD

- Voltage: 240-460V

- Power(W): 22kw

- Dimension(L*W*H): 40m*30m*16m

- Weight: 30tons

- After-sales Service Provided: Overseas third-party support available

- Machine type: crude Cooking oil refining plant

- Refining method: Physical or Chemical

- Oil standard: 1st to 4th class oil

- Processing capacity: 1-100tpd

- Heating method: steam heating

- Cooling method: circulated water

- Steam consumption: less than 300kg/ton

- Water consumption: 300kg per ton oil

- Electricity consumption: 22kw per ton oil

- Bleaching earth: 3-10kg per ton oil

After discovery of oil in the Assam state of India in late 1880s, the first oil refinery was set up at Digboi. Digboi Refinery was commissioned in 1901. [1] Following is a list of oil refineries in India, per the Petroleum Planning and Analysis Cell of the Ministry of Petroleum and Natural Gas, Government of India, [2] arranged in decreasing order of their capacity.

BPCL Kochi Oil Refinery is the largest public sector refinery in India, located at Ambalamugal near Kochi in Kerala. The crude oil refinery has a production capacity of 15.5 million tonnes per year and was acquired by the BPCL. Mangalore Refinery Oil and Natural Gas Corporation. Mangalore Refinery is part of ONGC to process crudes with

Oil Refineries In India Geography Notes Prepp

- Type: Cooking oil refinery equipment

- Use: Cooking oil refinery equipment

- Production Capacity: high

- Voltage: 220V, 380V, or other

- Power(W): depend on the capacity

- Steam consumption: 450kg/T oil

- Capacity: based on the requirement

- Deodorization loss consumption: ≤0.5%

- Bleaching earth consumption: 5~50Kg/Toil

- Electric consumption: 28kwh/T oil

- Phosphoric acid: 2~3kg/T oi

Indian Oil, the country's second-largest oil refinery, is ranked 19th in the world. In 2018-19, India produced 34.2 million tonnes of crude oil. This article will explain to you about Oil Refineries which will be helpful in preparing Geography for the UPSC Civil service exam.

Worldwide, Myande has supplied more than 500 oilseed crushing lines and more than 150 oil refinery lines, including 30 oil refinery production lines with capacity above 800t/d and 20 oil refinery production lines with capacity above 1,000t/d. The picture below shows location refinery plant equipment Myande has supplied.

A Closer Look At Soybean Oil Manufacturing Plant Cost

- Type: Processing Equipment

- color: silver

- description: continuous

- steam consumption: 450kg/T oil

- phosphoric acid: 2~3kg/T oil

- power consumption: 28kwh/T oil

- Bleaching earth consumption: 3~5Kg/T oil

- Waste bleaching earth oil content: <35%

- Deodorization loss consumption: ≤0.5%

Whether you invest in a soybean oil plant in India or elsewhere, you would do well to keep in mind these fundamentals about investing in soybean production. Request a callback Since 1939, Kumar has been delivering dependable process engineering solutions to the oils and fats industry.

This integrated Oil Palm project will include a cutting-edge oil palm factory (Palm Oil Processing and Refinery), a zero-discharge effluent plant, a palm waste-based power plant, and additional structures and go-downs for support purposes. This factory marks the first Oil Palm factory in Arunachal Pradesh and India's first Oil Palm Factory under NMEO-OP.

Nrl Md Shares Insights On How Major Expansion, Green Energy ..

- Usage: Oil

- Type: Cooking Oil Refinery Machine, Cooking oil processing machine

- Automatic Grade: Semi-Automatic

- Production Capacity: 2t-2000t per day

- Voltage: as requirement, 380V

- Power(W): according to capacity

- Dimension(L*W*H): according to capacity

- Weight: according to capacity

- Press: Cold and Hot Press

- Extraction: solvent extraction

- Refining: physical Refining or Chemical Refining

- Refining Method: batch refining or continuous refining

- Who We are: The leading manufacture

NRL MD: The company faces challenges in terms of transportation and production costs. To address these, they have partnered with Oil India Limited to construct a nearly 600-kilometre pipeline from Numaligarh to Siliguri, with plans to expand its capacity to handle increased production after the upcoming expansion.

Vedanta Announces Demerger Of Diversified Businesses ..

- Usage: Cooking oil making

- Type: Cooking Oil Refinery Machine, Cooking oil refinery machine

- Production Capacity: 5TPH-80TPH

- Voltage: 380V/50Hz

- Power(W): 22kw

- Dimension(L*W*H): 1.5*2.6*3.6M

- Weight: 2 TONS

- Materials: Carbon steel Q235 and SS304

- Performance: Hight and stable

- Princple: Physical squeeze

- Who we are: Manufacture

- Impurity content of crude oil: ≤0.2%

- Motor: SIEMENS

- Finished product: Grade 1 cooking oil

Significant production growth is anticipated as Gamsberg Phase 2 ramps. Vedanta’s copper business is capable of producing more than a third of India’s copper, Vedanta Copper’s assets in India consist of custom smelter, a refinery, a phosphoric acid plant, a sulphuric acid plant and a copper rod plant.

- How Indian oil refineries are achieving a sustainable future?

- IndianOil refineries have an ambitious growth plan for capacity augmentation, de-bottlenecking, bottom upgradation and quality upgradation. On the environmental front, all IndianOil refineries fully comply with the statutory requirements. Several Clean Development Mechanism projects have also been initiated.

- Which company has the largest refining capacity in India?

- As a group, Indian Oil Corporation has the largest refining capacity, with nine refineries located across western, northern and north-eastern regions of India. The Jamnagar Refinery by Reliance Industries Limited is the largest refinery in the world and has the largest Nelson Complexity Index in India of 21.1.

- How IndianOil refineries are growing?

- Procedures for the commissioning and start-up of individual units and the refinery have been well laid out and enshrined in various customised operating manuals, which are continually updated. IndianOil refineries have an ambitious growth plan for capacity augmentation, de-bottlenecking, bottom upgradation and quality upgradation.

- Which is the largest refinery in India?

- The Jamnagar Refinery by Reliance Industries Limited is the largest refinery in the world and has the largest Nelson Complexity Index in India of 21.1. Various refineries are undergoing capacity expansions, and the Barmer Refinery was expected to be commissioned in January 2024. Expected to commission in January 2024.

- What are the major refinery expansion projects in India?

- Refinery Expansion Projects India is scaling up its refining capacity with major projects underway: Cauvery Basin Refinery (CBR), Nagapattinam: Capacity to increase from 1 MMTPA to 9 MMTPA. Numaligarh Refinery: Expansion from 3 MMTPA to 9 MMTPA. HPCL Rajasthan Refinery Ltd.:

- Is India the second-largest refiner in Asia?

- India, the world's fourth-largest refiner, reported a refining capacity of 256.8 million metric tons per annum (MMTPA) as of April 2024, as per the Petroleum Planning and Analysis Cell (PPAC). With 22 operational refineries, private firms hold a significant 34.3% share, positioning India as the second-largest refiner in Asia.