Qiyi Machinery Leading Palm Oil Refinery Manufacturer

- Usage: Edible oil refining equipment

- Type: Small size,tailored to small factory

- Production Capacity: 6 T/D

- Voltage: Adjustable

- Steel type: carbon steel or 304 steel

- Phosphoric acid: 2~3 kg/T oil

- Electric consumption: 28Kwh/T oil

- Alkali: acid valuex1-3kg/T oil

- Steam consumption: 900Kg/T oil

- Water: 150Kg/T oil

- Bleaching earth consumption: 3-5 Kg / T oil

- Circulating water cooling water yield: 150M3/H

- Refining rate: 1-refining consumption %

- Waste bleaching earth oil content: < 25-35%

The aim of palm oil refining is to convert the crude palm oil into qualified edible oil through removing its objectionable impurities to required levels. Palm oil refining process plays an important role in the production of palm oil. Choosing an ideal palm oil refinery manufacturer would be an essential step to start the palm oil refining.

The second stage: palm oil refinery plant installation and commissioning stage: 1, the salary cost of the engineer. When installation the palm oil refinery plant, palm oil refinery plant manufacturers usually arrange engineers to guide the installation. The installation period is usually about 2 months.

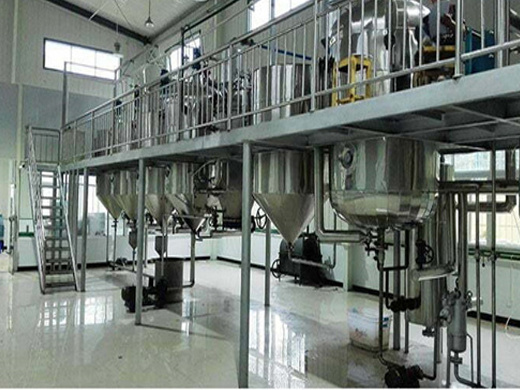

Palm Oil Refinery Plant

- Usage: Cooking oil

- Type:

- Production Capacity: Acorrding to your require

- Voltage: 380V/50Hz

- Power(W): 22kw

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- Supplier type: factory

- Soften water: 150Kg/T oi

- Refining rate: Refining consumption Less than 1%

- Texture: Mild steel and SS

- Steam consumption: 500Kg per ton

- Solvent consumption: Less than 250g per ton

- Electric consumption: Less than 10kwh per ton

- Bleaching earth consumption: 3-5Kg/Toil

- Processing: Oil press, extraction, refinery

- Item: oil processing equipment

We are leading manufacturers and suppliers of Palm Oil Refining Plants to process the crude Palm oil into refined Palm oil. We at Tinytech Udyog are determined to provide Palm Oil Refinery Plants to process the Crude Palm Oil into Refined Palm Oil. Palm Oil Refining can be done easily on our small scale refinery plants.

Professional palm oil processing manufacturer, help you build tailor-made palm oil refinery plant for processing vegetable oil or edible oil products! Low cost, premium performance! Palm oil deodorization is the final process of edible palm oil refinery plant. It is a result of heating-crushing and heating extraction development.

Cost On Palm Oil Refinery Plant

- Type: Oil refining

- Use: Make high quality oil

- color: silver

- capacity: 5-10T/D

- brand: LD'E

- outstanding: low price,fast return

- material: stainless steel

- oil material: Cooking,Cooking,Cooking,etc.

- certificate: ISO9001

- scale: intermittent

- Usage: vegitable oil refinery

The cost to start and operate a palm oil refinery plant covers a lots of aspects. QIYI Machinery, as a reliable and professional manufacturer and supplier for palm oil processing machinery and palm oil refining equipment, will tell you how to calculate the cost of running a palm oil refinery plant. Cost of Setting Up A Crude Palm Oil Reinery Plant

We are deling in the Palm Oil Refinery Plant and offers the products at the best prices to our clients. Gopal Expeller Company Shimlapuri, Ludhiana Plot No.4146/1, Guru Nanak, Guru Nanak Street No.7, Simla Puri, Shimlapuri, Ludhiana 141003, Dist. Ludhiana, Punjab

Palm Oil Refinery Plant Manufacturer &Amp; Exporter Goyum Indonesia

- Type: Cooking oil refining plant

- Use: Cooking oil refining plant

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Equipment material: Stainless steel,carbon steel

- Application: Refine crude oil

- Phosphoric acid: 2~3 kg/T oil

- Waste bleaching earth oil content: <35%

- Electric consumption: 28Kwh/T oil

- Bleaching earth consumption: 5~50Kg/T oil

- Steam consumption: 450KG/T oil

- Circulating water cooling water yield: 150m³/H

- Deodorization loss consumption: ≤0.5%

The pre treated oil taken into the bleacher under a vacuum of 650 700 mm hg and with a raise in temperature upto 110°C by mixing the bleaching earth 0.8% to 2% based on the quality of the crude palm oil with a retention time of 30 to 45 minutes and all unwanted compounds are coagulated and absorbed by the bleaching earth.

Best Palm Kernel Oil Refinery Machine Supplier Manufacturer

- Usage: for cooking edible oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 20-2000TPD

- Voltage: 380V

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Note: 2 years spare parts for free

- Color: can be customized

- Capacity: 1-1000TPD

- Material: carbon steel & stainless steel

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Advantage: easy use,energy saving,simple operation

- Function: get high quality cooking oil

- Feature: Full Automatic and Multifunction

- Package: Standard

The Small Oil Refinery increases your maximum fuel capacity. It takes 3x3 land regardless of level and requires roads. It is not possible to sell or warehouse this building

The setup you have, including both advanced refining and cracking, gets 97.5 petrol per 100 crude. Switching back to basic refining drops that to 45 petrol per 100 crude. I guess maybe if you were making it from scratch and had more crude oil than you knew what to do with, it might be quicker to stick to basic.

Oil refinery, commonly known as "oil refining", uses physical and chemical methods to remove the solid impurities contained in crude palm kernel oil, like free fatty acids, phospholipids, gum, wax, pigment, odor through a series of Palm Kernel Oil Refining Process collectively, which finally can improve the tasete, quality and shelf-life.

- What makes palmindo a good company?

- PALMINDO uses the best quality Crude Palm Oil and Crude Palm Kernel Oil to process with the latest and automation technology process, ensure only the highest quality products delivered to customer. All our products will go through Quality Control checking to ensure our customer get the best product consistently.

- What is palmindo's core business?

- PALMINDO’s primary core business is Refinery and Fractionating raw materials (Crude Palm Oil/CPO and Crude Palm Kernel Oil/CPKO). PALMINDO has 2 refinery plants with joint capacity of 1500 MTPD. Our modern and highly integrated production facilities are maintained by a team of highly skilled workforce.

- Does palm oil produce pericarp & kernel oil?

- The palm oil fruit can yield two distinct edible oil – the pericarp and the kernel parts of the palm fruit. The physical refining process is suitable for both crude palm oil and palm kernel oil. Our physical refining plants are built for large-scale production.

- What is cpko palm oil?

- CPKO (Crude Palm Kernel Oil) is obtained from the kernel of the oil palm fruit. Its composition and properties differ significantly from palm oil. CPKO is produced by mechanical extraction of the kernels which are pre-dried in palm oil mills through a partial vacuum process.

- What is the Physical refining process for palm oil?

- The physical refining process is suitable for both crude palm oil and palm kernel oil. Our physical refining plants are built for large-scale production. Our process technology is based on a fully continuous and automatic fractionation of palm oil.

- What is indopalm?

- Indopalm generate own Electricity using Palm kernel shell as renewable biomass fuel and one of the most Environmental friendly fuel never making any harm to the Environment . To be a leading company in the palm oil Indutries known for its Excellence.