How Much Does A Medium Cooking Oil Refinery Plant Cost

- Usage: Cooking Oil refining line, Cooking oil refining line

- Type: Cooking oil refining machine, Cooking oil refining line

- Production Capacity: 100%

- Voltage: 400/380/220V

- Power(W): 82 KW

- Dimension(L*W*H): 18*10*10 meter

- Weight: 5600kg

- Power: Electricity/water/steam

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Certifate: ISO 9001&BV&CE

- Operating: Easy operate

- Brand: LD

- Made in: China

- Color: According to customers

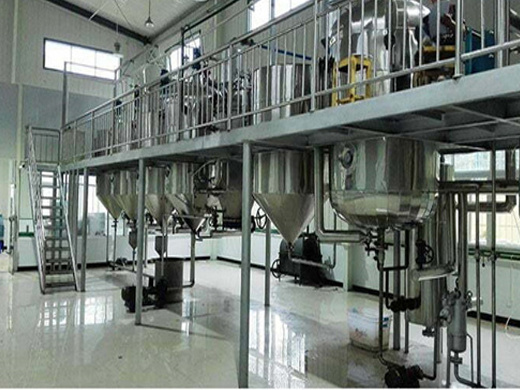

Equipments include in medium cooking oil refinery plant 1. Decoloring tank: bleach pigments from oil. 2. Deodorizing tank: remove the un-favored smell from decolorized oil. 3. Oil furnace: provide enough heat for the cooking oil refining plant which need high temperature of 280℃. 4.

Henan Glory's product range includes a wide range of edible oil refineries, which can be divided 1-20tpd batch type edible oil refining machine, 10-50tpd semi-continuous edible oil refinery plant and 30-1000tpd full-continuous edible oil refinery plant by type.

Cooking Oil Refining Plant

- Usage: crude Cooking oil refinery equipment

- Type: Cooking Oil Refinery Machine

- Production Capacity: 30T~100T/D

- Voltage: 220V/380V

- Power(W): 28KWh/T

- Dimension(L*W*H): according to capacity

- Brand: Qi'e

- Steam consumption: <280KG/T (0.8MPa)

- Business type: manufacturer

- Crude oil moisture and volatile matter: <0.3%

- Item: crude Cooking oil refinery equipment

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Operating pressure: normal/negative pressure

- Dimension: depend on capacity

We provide 2TPD 5,000 TPD capacity cooking oil refinery plants and professional turnkey oil refining solutions for various crude oils, from factory consultation, cost budgeting, project design, equipment manufacturing, and installation to technical support.

The costs of setting up a small scale edible oil refinery plant is influenced by the investment cost for plant land, small scale edible oil refinery machine, crude oil raw materials. Total investment cost may range from $10,000 to $150,000.

How Much Does A Sunflower Oil Refinery Plant Cost

- Usage: Automatic Cooking oil mills manufatur

- Type: Automatic Cooking oil mills manufatur

- Production Capacity: 50TPD~100TPD

- Voltage: 220V/380V

- Power(W): according to capacity

- Dimension(L*W*H): depend on capacity

- Weight: according to capacity

- Item: Automatic Cooking oil mills manufatur

- Business type: manufacturer

- Application: various oil plants

- Brand: Qi'e

- Material: Stainless steel, Carbon steel

- Quality: high

- After-sale service: yes

- Origin: China

Batch type sunflower oil refining machine, heating methods can mainly be divided into electric heating refining and heat transfer oil refining.The electric heating method for refining mainly relies on electricity to provide heat source for the equipment. Our electric heating refining equipment has a processing capacity of 0.5TPD, 1TPD, and 2TPD

An oil extraction machine, also called an oil press or expeller, uses high pressure and heat to “squeeze” the oils out of a plant product. Those products — including seeds, nuts, vegetables, fruits and leafy plants — release their oils through this mechanical process, which is often done without adding any chemicals.

Complete Sunflower Oil Production Line. Sunflower Oil Mill ..

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine, Cooking oil processing equipment/refinery plant

- Production Capacity: 10-5000T/D

- Voltage: 220V/380V/415V

- Power(W): Based On Cooking oil processing equipment/refinery plant Capacity

- Dimension(L*W*H): Based On Cooking oil processing equipment/refinery plant Capacity

- Weight: Based On Cooking oil processing equipment/refinery plant Capacity

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Warranty: 12 Months

- Function: Vegetable Oil

- refined Cooking cooking oil machine: Cooking,etc

Batch type oil refining plant: Capacity is 1~30 TPD. It featured less investment, convenient operation, and a small footprint. Semi-continuous Oil Refining Plant: Capacity is 30~50 tons TPD. It has the advantages of low power consumption and a better refining rate than batch-type. Full continuous oil refining plant: Capacity is 50 TPD 5,000

Cooking Oil Refinery Machine From China Myande

- Usage: edible oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 98%

- Voltage: 220V/380V/440V

- Power(W): 11KW

- Dimension(L*W*H): 1.5*2.6*3.6M

- Weight: 0.5-10T

- Product name: edible oil refinery plant

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Application: all kinds of oil seeds

- Function: get grade 1 cooking oil

- Warranty: 365 days

- Feature: Multifunction High Efficient

- Model: LD88

- Quality: 15 years service time

- Advantage: 35 years experience

- Color: Nippon

Worldwide, Myande has supplied more than 500 oilseed crushing lines and more than 150 oil refinery lines, including 30 oil refinery production lines with capacity above 800t/d and 20 oil refinery production lines with capacity above 1,000t/d. The picture below shows location refinery plant equipment Myande has supplied.

- How much does it cost to build an oil refinery?

- Estimated Total Cost Taking all these factors into account, the cost of building an oil refinery can range from 10 thousand dollars for smaller operations to over $300 thousand dollars for large-scale, complex refineries with high throughput and advanced technology.

- Why do petrochemical refineries need a heat exchanger?

- Heat exchangers are crucial in petrochemical refineries for transferring heat between fluids, which is vital for energy conservation and process efficiency. They preheat crude oil before it enters distillation columns and cool down processed products, making the refining process more efficient and cost-effective. Types of Heat Exchangers:

- How do I determine the cost of major plant equipment?

- major plant equipment must be known. The most accurate est imate of the purchased cost of a piece of major equipment is provided by a current price quote from a suitable vendor. a. Six-Tenths Factor available. This rule states that if the new piece of equ ipment is similar to one of another capacity for which cost data are available.

- What is a petrochemical refinery?

- Petrochemical refineries are sophisticated complexes where raw materials such as crude oil and natural gas are converted into a wide array of valuable products, including fuels, plastics, and chemicals. The efficiency, safety, and profitability of these operations hinge on the use of specialized equipment.

- How can refinery equipment performance be optimized?

- Optimizing equipment performance is crucial for maximizing refinery efficiency. This involves a combination of factors, including: Regular Maintenance and Inspection: Proactive maintenance schedules and thorough inspections help prevent equipment failures, reduce downtime, and extend the lifespan of machinery.

- How does equipment performance affect refinery efficiency?

- The equipment’s condition, capacity, and technological advancement directly impact the refinery’s overall productivity, energy consumption, and environmental footprint. Optimizing equipment performance is crucial for maximizing refinery efficiency. This involves a combination of factors, including: