How is Corn Oil Extracted? Trucent

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Model number: SFE-50

- Application: Liquid

- Key selling points: High precision

- Weight (KG): 1000

- Outgoing inspection video: Provided

- Machinery test report: Provided

- Main components marketing warranty: 2 years

- Main components: PLC

- Power (kW): 36

- Dimension (L*W*H): 5500*5000* 4500 mm

- Power Supply: Three Phase Four Lines 380V/50Hz 36Kw

- CO2: Food Grade ≥99.5%

- Material: SUS304/SUS316L

- Function: Oil Extract

- Extraction Type: Super critical CO2 fluid extraction

In order to understand the corn oil extraction process and how corn oil is extracted during ethanol production, it helps to first understand how corn is processed. Broadly speaking, corn processing is broken up into wet milling and dry milling. Processing Corn by Wet Milling Wet milling is primarily used to make food ingredients: sweeteners, … Continued

Glycerol can significantly impact efficiency of oil separation equipment as it leads to glycerol-in-oil emulsions and causes fouling in equipment. Also, any non-hydrolyzed starch present in the stillage and ultimately in the syrup, will serve as an oil-in-water emulsion stabilizer that will negatively impact oil separation (Kasprzak et al., 2018).

Ethanol Corn Oil Extraction Solutions Trucent

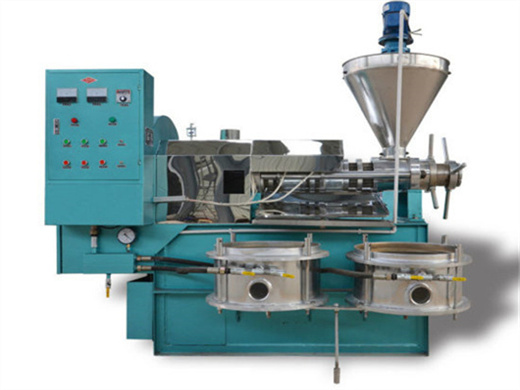

- Usage: Cooking Oil

- Capacity: 5TPD-100TPD

- Voltage: 220V/380V

- Dimension (L x W x H): 1050*800*1400mm

- Weight: 330 KG

- Main components: Motor, Bearing, gearbox

- Oil capacity: 40-500 kg/h

- Material: stainless steel and carbon steel

- Use range: sunflower oil, Cooking oil, Cooking oil, peanut oil, sesame oil, soybean oil,

- Rate Oil content: less than 8%

- Wearing parts: loops\spirals\bars

- HS CODE: 8479200000

Corn Oil Extraction: Technology, Chemistry, and Expertise. Over the past several years, Trucent has built a proprietary corn oil extraction and recovery platform. Working in more than 40 ethanol plants, we’ve processed thousands of samples, looking at 250 factors, and then isolating the 50+ key factors that help us determine how to adjust

Corn Oil Extraction The oil is typically extracted from the germ by a combination of mechanical expression and hexane extraction. During starch extraction process the germ is seperated from kernel after cleaning and steeping. The oil is seperated from germ through steps given in Figure 5. Refining involves several steps: (i)

20TPD Copra Oil Mill Plant in Philippines

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 15-25 kg/h

- Voltage: 220 V, 50 HZ

- Power: 3.15 KW-5.5 kw

- Dimension (L*W*H): 600*600*1260\700* 830*1260

- Weight: 95\140kg

- advantage: Simple operation

- Application: Oil pressing

- Material: 304 stainless steel

- Features: cold pressing \hot pressing

- Production of oil: 15 kg/h

- Applicable raw materials: unlimited type

- Press mode: screw press, raw and cooked can be

- Filtration: filtration empty

This is one of our project in Philippine a medium scale copra oil mill, including 20TPD oil extraction line and 10TPD oil refinery line. The daily capacity is processing 20 tons of copra (desiccated coconut) and get 10 tons of refined coconut oil.

The corn oil can be further refined from a crude product to an edible product. Oil Refining and Processing. Extracted and desolventized corn oil must be further processed to make an edible product. Edible oils are refined to improve the flavor, odor, color and stability using processes that degum, neutralize, bleach and deodorize the oil. These

Corn Oil Extraction Plant. Complete Corn Germ oil production line

- Usage: Cooking Oil

- Voltage: 380 V

- Dimension (L*W*H): 2300*820*1420 mm

- Weight: 1100 KG

- Main components: Motor, Others, Gear, Bearing, Motor

- Oil type: Cooking oil

- Residual cake oil(%): ≤8.0

- Advantage: High oil yield

- Power of the main electric motor (kw): 22

- Raw material: Sunflower, soybean, Sunflower

- Processing capacity (t/24): 11

- Rotation speed of spiral shafts (rpm): 28~38

The corn oil extraction plant extracts oil from the corn germ by mechanical pressing or prepressing combined solvent extraction. We supply 1-1,200 TPD complete corn germ oil production lines. A corn oil production line, whether small or large-scale, is tailored to optimize the oil yield, quality, and cost-efficiency of corn oil.

Advanced Corn Oil Extraction Technology Oil Mill Plant

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 5TPD-100TPD

- Voltage: 220V/50HZ three-phase

- Dimension (L*W*H): 1055*805*345mm

- Weight: 27.1 KG

- Main components: Motor, motor

- Oil name: Cooking oil cold press machine

- Advantage: high oil yield

- Character: easy to move

- Function: oil pressing

- Color: customer required

- Quality: High level

- Operation: Easy

- Keyword: Soybean oil solvent extraction equipment

- Model: TS-BXG-128

We design complete corn oil extraction plant, we provide professional corn oil extraction technology, we offer quality oil processing machines especially for corn oil extraction. We have a good reputation acros s the globe. Detailed Corn Oil Extraction Process. In the process of corn oil extraction, the crude oil is heated to vaporize the