Virgin Coconut Oil Machinery Gemtech Projects

- Usage: Edible Oil

- Video outgoing inspection: Provided, Provided

- Main components: engine, gearbox, pressure vessel

- Power source: electric or steam

- Process: Distillation

- Voltage: 380V

- Power: Customer Requirement

- Dimension (L*W*H): Demands

- Weight: 200 KG

- Material: Stainless steel

- After-sales service: Online support

- Packaging: Wooden box

- Capacity: 100-10000L/h

- Sealing: Machinery seal

- Raw material: Grass, flower, roots, seeds, resin, etc

- Control of temperature (): PID Auto Control

- Type of Marketing: Ordinary Product

Virgin Coconut Oil Production Machinery by Gem helps in production of VCO to meet prescribed standards and to be suitable for human consumption. Gem is supplying machines to Phillipines, Srilanka, Indonesia and Fiji for production of Virgin Coconut Oil. Gem manufactures small scale to large scale virgin coconut oil machinery. A Leading

Highly efficient technology for massive production of desiccated coconut. Gem manufactures band dryer of capacity upto 1600 kgs / hr. Also suitable for desiccated coconut chips, threads, copra, virgin coconut oil production. Apron tray with air circulating fan technology to dry desiccated up to 1500 kgs / hr. Easy operate & control.

Turnkey Virgin Coconut Oil Processing Plant installed in India

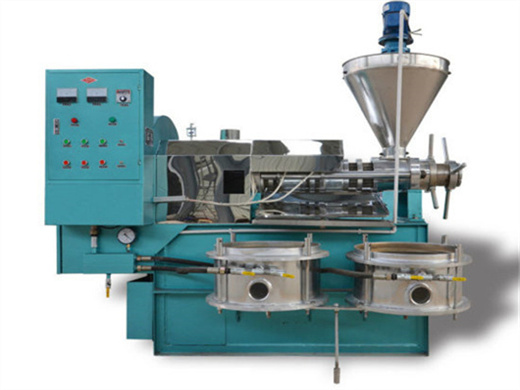

- Usage: Edible Oil

- Capacity: 5-2000T/D

- Voltage: 380V/220V

- Power ( W): Up to specification

- Dimension (L*W*H)): 1360*950*1170mm

- Weight: Up to specification

- Certification: ISO, SGS, BV

- color: green or red

- material: carbon steel or stainless steel

- package: naked or according to customer's require

- delivery location date: within 35 days of customer confirmation of the order

In order to remove these impurities, the oil is sent to an oil filter press machine. Virgin Coconut Oil is water clear in colour, has a mild sweet aroma. VCO is chemical and additive-free and is the purest form of coconut oil. Virgin Coconut Oil is currently a hot topic due to its benefits to human consumption and the researchers challenge the

Refined coconut oil is the processed coconut oil that does not contain any impurities. It is more precisely called RBD coconut oil. RBD stands for refined, bleached, and deodorized. Therefore, refined coconut oil has a neutral scent and flavor. The smoke point of refined coconut oil is higher than that of unrefined coconut oil.

Coconut Processing Line IBC MACHINE

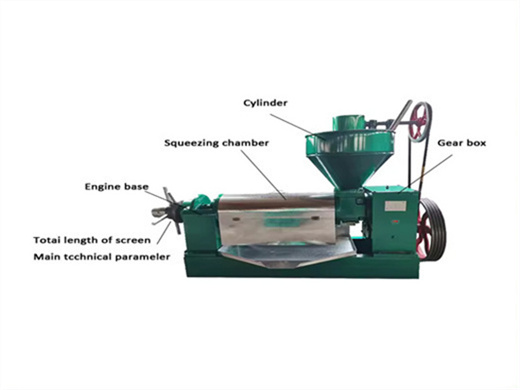

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 20-2000TPD

- Voltage:380V

- Power (W):Standard

- Dimension (L*W*H):standard

- Weight:standard

- Certification:CE,ISO

- Application: machinery prices of oil mill

- Name: oil, sesame oil cold press oil extraction machine

- Note: 2 years free spare parts

- Oil pretreatment 1:cleaning section

- Oil pretreatment 2:Breaking section

- Oil pretreatment 3:Embryo pressing section

- Embryo pretreatment oil 4:Softening section

- Pressing part:Oil pressing section

- Extraction part: oil extractor

- Refining part: Complete line for refining of oil

Home / Complete Line / Fruit&Vegetable Processing Line / Coconut Water/Milk Processing Line Previous Next Coconut Water/Milk Processing Line admin 2024-09-25T08:47:28+00:00

Coconut oil production line Description. Coconut oil, also known as copra oil, is an edible oil extracted from the kernel or meat of mature coconuts harvested from the coconut palm, Coconut oil is called the healthiest edible oil in the world. Filipinos call coconut oil “the drugstore in a bottle.”

Snack Food Production Line Production Line & Turnkey ..

- Usage: Cooking Oil

- Capacity: 30-300T/D

- Voltage: 380V, 50HZ

- Power: depends on capacity

- Dimension (L*W*H): according to capacity

- Weight: according to capacity a

- color: blue, yellow or red

- capacity: 30-300T/D

- function: extract oil from seed cake

- application: all kinds of oilseed cake

- size: depends on capacity

- weight: depends on capacity

- certificate: CE, ISO

- containers: 3-20 pieces of 40HQ

- production time: 30 days

- installation time: 30 days

- Certification: CE, ISO

Tsung Hsing is a food machinery manufacturer. It has been sold all over the world since 1965. We serve as a food machine expert and turnkey project planning consultant. Provide comprehensive food solutions for frying production lines. Located in Taiwan, TSHS is a Snack Food Production Line food processing machinery manufacturer since 1965. CE certified food processing machinery including

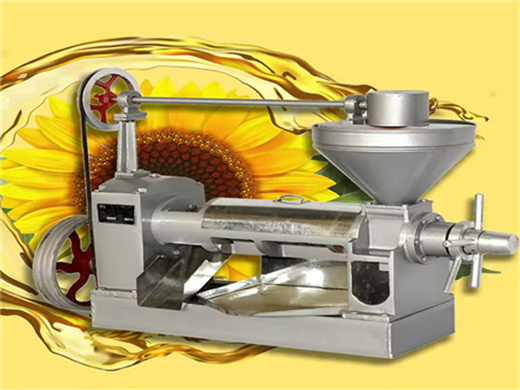

Coconut Oil Pressing Machine for Sale|Low Cost & Premium Quality

- Usage: Edible Oil

- Voltage: According to customer demand

- Power (W): According to project

- Dimension (L*W*H): According to project

- Weight: According to customer demand

- Certification: ISO9001-2008, CE, BV

- Color: According to customer demand

- Production material: Carbon steel, steel stainless

- Raw material: Cooking

- Working principle: Mechanical principle

- Warranty period: One year

- English manual: Yes

- Factory visit: Yes

QIYI Machinery is a popular equipment manufacturer and supplier among vegetable oil production sector, well known for quality and services, distributing coconut oil pressing machine including screw oil pressing machine, integrated oil expeller with filter and refining machine at competitive price.

- What are the steps of copra oil mill plant?

- At the copra oil mill plant, the copra undergoes the following steps: Copra Drying, Copra Cutting, Cooking / Conditioning, Pressing, Filtration, Oil storage and Filling. The Copra dryer is used to dry fresh coconut kernel from 35 – 40% moisture content to 5 – 7% using hot air.

- What is copra oil expeller?

- Copra Oil Expeller is perfect for medium or large oil mill plants. We are well-known manufacturer of oil extraction machine and our screw press are working successfully in more then 51 countries of the world.

- How is oil expelled from a copra?

- The oil is expelled from the copra by the pressure exerted by a continuous rotating warm shaft in the barrel or cage of the press. The barrel is built with openings to allow the escape of oil. Crude Expelled oil generally contains 5 – 10% suspended solid (foots). A filter press is used to separate these solids from crude oil.

- What is the oil content of copra?

- The copra contains 60 – 65% oil content. After a double stage pressing, about 8 – 9 % residual oil is left in the copra meal which is an excellent source of protein supplement for grass fed animals. The Disintegrated Copra is conditioned using Steam in a Vertical Cooking Kettle.