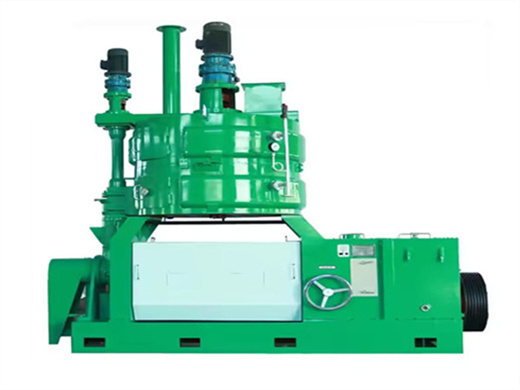

best sale soybean oil extractor machine soybean oil plant

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Voltage: 380 V, 220 V

- Power (W): 22 kW

- Dimension (L*W*H)): depends on mode

- Weight: depends on the mode

- Certification: ISO9001

- Item: cooking oil extraction equipment

- Production process: cooling, crystallizing, filtering

- Production process: cooling, crystallizing, filtering

- Oil quality: natural and green

- Oil yield: high oil yield

- By-product: edible wax

- Steel quality: stainless

- Raw material: Vegetable seed

- Shipping: by sea

soybean oil extraction machine oil pressing in zambia Best. high quality soybean oil processing machine for sale. soybean oil press machine in soybean oil processing plant. soybean oil solvent extraction plant: solvent extraction is to use n-hexane to extract the oil from the processed oil seeds or cakes. the whole solvent extraction plant is anti-explosion considering of production safety

The first type of oil sample, extracted by dissolving crushed canola seeds in hexane in the laboratory will be called chemical method, the second type by pressing canola seeds through the device shown in Fig 1 will be called cold pressed, and the third type taken from commercial canola oil brands will be referred as commercial brands in the

Mustard / Canola / Rapeseed Solvent Extraction Plant

- Usage: Cooking Oil

- Capacity: 50-1000 t/d depends on your request

- Voltage: 380 V

- Power (W): As sales capacity of oil mill

- Dimension (L*W*H): As sales request of oil mill

- Weight: As sales output of oil mill

- material: stainless steel

- residual oil in the cake: less than 1%

- range of raw materials: sesame, soybean, rice bran, peanut , Cooking kernel, rapeseed,

- Extractor system: roasting system

- Moisture in food: 12~13%

- Residual solvent: 300 ppm

- Solvent: solvent oil No. 6

- Solvent consumption: 4kg/t

- Mechanical impurities: 0.2%

The Solvent Extraction plant can’t be processed with flakes due to its high oil content. The Oil content are to handled with expander with squeezo matic arrangement. Where 20 % of the oil will be drained and collets containing 25% 28% oil will be transferred for extraction. The collets is with 35% more porosity than the flakes.

Machine Type: vegetable seed oil mill plant, Production Capacity: ≥750kg/h, Dimension(L*W*H): 41*28*29cm, Motor Power: 200W, Certification: CE, ISO Palm, After warranty service: online support or on set oversea, Raw Material: vegetable seed, Market: lesotho

hot sale cooking oil extraction machinery/soybean oil in lesotho

- Usage: Cooking Oil

- Voltage: 220 V/380 V/440 V

- Power (W): 5.5-22 KW

- Dimension (L*W*H): 48m *12M*15M(30TPD)

- Weight: 30 tons

- Certification: ISO9001

- Raw material: Vegetable seeds

- Function: Press of oilseeds

- Advantage: Energy saving

- Material: Q235 carbon steel

- Application range: Types of oilseeds

- Character : Screw Oil Pressing Machines

- Color: Facility Use

- Feature: High Efficiency Multifunction

Factory direct supply cooking oil processing machine and edible oil refinery machine for processing soybean oil, groundnut oil, sunflower oil, cottonseed oil, canola oil, rice bran oil with best price, low cost, high quality40TPD soybean oil extraction plant project in Zimbabwe.Hot-sale cooking oil processing plant.

edible oil refinery plant made hit in lesotho. September 23, 2024. oil expeller peanut oil making machine in lesotho. canola oil extraction machine;

Variability of quality traits in canola seed, oil and meal ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 10--1000TPD

- Voltage: 220V, 380V

- Power (W): 11 KW

- Dimension (L*W*H): According to its capacity

- Weight: 1000kg

- Origin: Henan, China

- Texture: Stainless steel or carbon steel

- Oil rate: High oil rate

- Product level: Turnkey project

- Raw Material: Canola seeds, Rice bran, Corn germ, Soybeans, Cotton seeds

- Consumption: Low consumption

- Operation: Fully automatic

- Type Desolventizer: DTDC

press and expeller plants are used due to lower capital costs than solvent extraction plants. However, because the oil is extracted by mechanical separation, the resulting meal is somewhat different to solvent extracted canola meal.

Extraction, nutrition, functionality and commercial ..

- Usage: Edible Oil

- Capacity: over 98%

- Voltage: 220V/110V

- Dimension (L*W*H): 545*200*320mm

- Weight: 12 KG

- Main components: motor, motor

- Oil type: cooking oil

- Product name: press screw oil

- Machine size: mini oil press machine

- Control mode: Automatic oil extraction machine

- Squeezing type: screw oil presser machine

- Function: Oil pressing

- Production: 6-800kg/H

- used for: sunflower, beans, cooking, etc .

- Material: 304 SS materials body, 316 stainless steel screw and chamber

- Machine color: silver

- continues working: 24 hours

Oilseeds are the most popular plant protein sources, owing to their widespread cultivation production. Canola/Rapeseed is the second most cultivated oilseed worldwide, after soybean, with an annual production of 19.4 million metric tons in Canada, the world's largest producer, in 2020/2021 (Canola Council of Canada, 2021).

- How is canola oil extracted?

- Canola oil is extracted using two main methods: Mechanical Press and Solvent Extraction. In the Mechanical Press method, Canola oilseeds are pressed in a series of Screw Presses / Expellers. This process does not use chemicals and leaves approximately 5-7% oil in the residual Cake/Meal.

- Which countries produce canola oil seeds?

- The major producers of canola oil seeds are the European Union, Canada, China, and India. The European Union and Canada are among the leading producers, and the Canola (and Rapeseed) oil is the 3rd leading source of vegetable oil, after soybean and palm oil.

- What is the process for canola seed processing?

- To process canola seeds, we need basic equipment including a Seed Cleaner, Seed Cooker/Kettle, Oil Press, Filter Press, Steam Boiler, Screw Conveyors, and Bucket Elevators. The process begins with seed cleaning, where canola seeds are separated and cleaned to remove impurities such as dust, metal, and plant stalks.

- What is the process of refining canola oil?

- Canola oil refining is the process to remove undesirable substances like phospholipids, free fatty acids, sterols, waxes, oxidation products, water, aromatic compounds, and pigments from crude canola oil, which adversely affect the quality and durability of the oil.

- What is canola oil and rapeseed oil?

- Canola (and rapeseed) oil is the third leading source of vegetable oil, after soybean and palm oil. Canola and rapeseed oil are the same thing, with canola being a variety of rapeseed that has lower erucic acid content and lower glucosinolates. The global production volume of Rapeseed oil has risen steadily over the last several years, and there are still investors who want to enter the Canola Oil Manufacturing industry.

- How is canola oil filtered?

- Canola oil is filtered through a two-step process. First, the extracted oil is transferred to a Vibro Separator or Screening Tank for preliminary separation of suspended solids, known as 'foots'. Then, the pre-cleaned oil undergoes final filtration in a filter press or vertical pressure leaf filter to obtain filtered canola oil.