How Much Does a Sunflower Oil Refinery Plant Cost

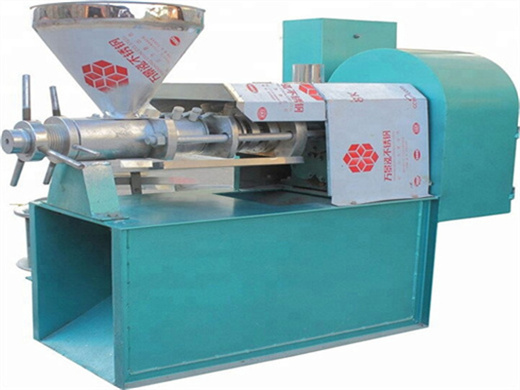

- Usage: Edible Oil

- Capacity: 15 TONS/DAY

- Voltage: 40 hp

- Dimension (L*W*H): 2921MM* 1400MM*2743MM

- Weight: 5500 KG

- Main components: motor, bearing, gearbox

- Oil type: cooking oil

- Oilseed extraction: cooking, cotton, sunflower, cooking, cooking, Sunflower

- ENGINE: 40 HP

- CAPACITY: 15 Tons/Day

- Post Warranty Service: Spare Parts

BEST Mini Sunflower Oil Refinery for Sale Low Cost Edible Oil Refinery Plant for Sale. Reference price for small oil refinery unit: $22,800 Edible oil refinery plant cost as low as $55,769. To ensure you make an informed investment decision, we recommend you share your specific needs such as production scale, equipment requirements and budget.

We specialize in designing and manufacturing complete oil mill plant, oil extraction plant projects for various oilseeds. We provide quality oil mill machinery for our customers. With rich experience in manufacturing and exporting oil mill machinery for different processing purposes, we are your trusted Chinese manufacturer of oil mill machines.

Fully Automatic Mustard Oil Mill Manufacturers & Exporters ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 150-300kg/h

- Voltage: 220v/380v/Customer request

- Dimension (L*W*H): 1900*1400 *1700mm

- Weight: 1100 KG

- Main components: motor

- Oil type: cooking oil

- Name: ejector price of oil in India

- Raw material: sunflower for cooking

- Function: oil pressing

- Operation: Automatic operation

- Advantage: Energy saving Low waste

- Oil rate: Food residual: 1%

- Capacity: Large

- Material: Stainless steel

- Types of processing: Screw pressing

- Continue working: 24 hours

Complete Turnkey Fully Automatic Mustard Oil Mill Installed in India. If you are interested in setting up a fully automatic cold press mustard seed oil mill plant, please let us know your requirement, we will send you a quotation with the list of most suitable extraction machines and equipment.

50TPD Corn Oil Extraction Plant and 15TPD Oil Refinery Line in Iran Small Soybean Oil Production Machine & Plant Installed in Nigeria >20TPD Oil Refinery Plant Project Coconut Oil Refining Process Expert Tips for smart investment High-Effect Rice Bran Oil Refining Process Low-Cost Solutions Proven Sunflower Oil Refining Process to Better

Physical and Chemical Process in Palm Oil Refining Plant

- Usage: Cooking Oil

- Capacity: 40 tons/hour

- Voltage: 380V/440V

- Power (W ): 30KW

- Dimension (L*W*H): 1200* 2800*1200 mm

- Weight: 500 tons

- Solvent consumption: 1.5 kg/ton of materials

- Oil color: Yellow

- project model: turnkey

- Raw material: Cooking fruit oil processing

- Manufacturing processing: automatic

- Welding: automatic welding

- Capacity: 10-100 tons/hour

According to the degree of automation, the refinery process can also be divided into Batch Refinery Plant, Semi-continuous Refinery Plant and Continuous Refinery Plant. Batch type is the ideal choice for mini and small sized production (1-20TPD), while the latter two are normally designed for middle-large size production line (10-50TPD).

The setup cost of this sunflower oil mill plant is around $500,000, which includes the equipment of 100ton/h oil production line, 4 ton/h steam boiler system, and installation and commissioning fee. Actually, each project is customized depends on the clients' specific situation and needs, which meas the cost depends on many differen factors.

Full automatic large capacity cooking oil refining machine ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Voltage: 380V

- Dimension (L*W*H): 2400mmx900mmx2000mm

- Main components: Motor

- Oil name: Oil press screw oil

- Color: stainless steel color or customizable color

- >Material: steel cardboard

- Service: OEM and ODM

- Size Packaging: 2000 mm x 1500 mm x 1450 mm

- Weight: 1300 kg

High Capacity and Efficiency: This full automatic large capacity cooking oil refining machine has a production capacity of 98-100% and can process various types of seeds and nuts to produce high-quality edible oil.

Botswana crude palm kernel oil refinery processing machine

- Usage: Cooking Oil

- Capacity: 500-2500 kg/h

- Voltage: 220 V/380 V

- Dimension (L*W*H): depends on the model

- Weight: 140 KG

- Key Selling Points: High Productivity

- Inspection Video outgoing: provided

- Main components warranty: 1 year

- Main components: engine oil

- Maximum capacity: 500 kg/ h

- Product name: small oil refinery machine

- Raw material: crude edible oil

- Capacity: 500-2500 kg/h

- Material: steel stainless

- Model: JLJ

- Advantage1: High efficiency

- Advantage2: Simple operation

- Price: factory direct price

- Application: Edible oil production

Usage: oil refinery plant; Type: vegetable crude oil refinery equipment, Refinery plant; Automatic Grade: Automatic; Production Capacity: 1-1000tpd vegetable crude oil refinery equipment; Model Number: vegetable crude oil refinery equipment; Voltage: 380v or according to the local voltage; Power(W): According to the capacity of vegetable crude

- What happened to Malaysia's oil refining capacity in 2021?

- Malaysia's oil refining capacity has remained mostly flat, but expanded to 955,000 barrels per day in 2021. This was due to the startup of oil refining facilities as part of RAPID, which remained at the same level in 2022 (Figure 1). Refining throughput declined year-on-year in 2020 during the Corona disaster, but has since picked up.

- What is Kertih petrochemical industry?

- petrochemicals production and crude oil refining in nearby Paka. As an industry specific development, Kertih’s transformation from a quiet and sleepy fishing village to a top-notch petrochemical hub was finally completed with the set-up of the PETRONAS Petroleum Industry Complex (P

- Which petrochemical companies should invest in Malay?

- UPC Group, Recron, Synthomer, Dairen, Mitsui and Reliance Group.Potential investors can expect to reap returns from existing integrated petrochemical complexes offering centralised utilities, eficient storage services, and a comprehensive transportation network that collectively help reduce capital and operational costs, thus positioning Malay

- Does Petronas operate petrochemical complexes in Melaka?

- Petronas also operates petrochemical complexes in Melaka, Kerteh and Gebeng. The RAPID project is expected to spur economic growth in the region, as well as attract domestic and foreign direct investments into the country.

- Is Malaysia a viable petrochemical hub in the ASEAN region?

- an u) a) a) a) ga ga (P mical Products in MalaysiaThe availability of feedstock at competitive price has made Malaysia a viable petrochemical hub in the ASEAN region, attracting almost RM33 billion of investments in 2018 from leading p sity Polyethylene (HDPE)Pengerang Petrochemical Company Sdn Bhd (to be ful

- Where are Cals products produced in Malaysia?

- cals products in Malaysia. RAPID has been progressing as scheduled and to be fu Q1 2020.Bintulu, SarawakHome to several gas-based petrochemical plants, Bintulu is also the largest producer of liquefied nat