Refineries United Plantations Berhad

- Usage: Cooking Oil

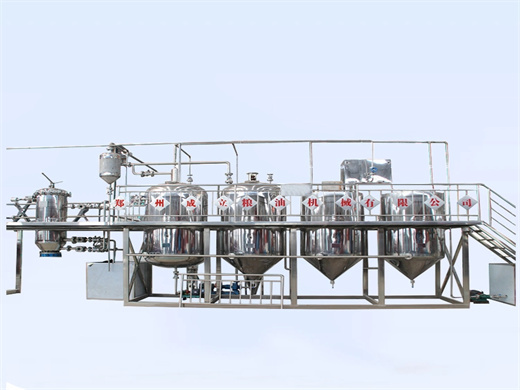

- Type: Cooking Oil Refinery Machine

- Production Capacity: High

- Voltage: 230V 380v 440v or others

- Power(W): 30KW

- Dimension(L*W*H): according to capacity

- Weight: according to the capacity

- Product name: Small vegetable oil production line Cooking oil refined Cooking oil

- Residue in cake: less than 1%

- Extractor type: rotary

- Vacuum degree: high vacuum

- Function: extract oil from seed

- Working mode: circulation usage of solvent and steam

- Solvent in crude oil: 350ppm

- Steam consumption: less than 450KG/T oil

- Oil getting method: pressing/extraction

- Advantage: save energy

INTEGRATED MILLING AND REFINERY COMPLEX. The UniFuji project was launched in 2016, and began operations in 2018. The common objective is to produce value-added palm fractions made from RSPO certified and traceable palm oil without the use of fossil fuels as well as complying with the highest possible food safety and quality standards in the world.

tain the minimum oil loss and most stable refined oil retaining more desirable nutrients, minimal refining has been developed as an al- ternative to conventional refining (Ghazani etal., 2013

Oils Fats Refining Equipment And Turnkey Plants

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine, small Cooking oil refinery plant

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Power(W): 30KW

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 1200 Tons

- Oil getting method: pressing/extraction

- Heating way: steam

- Oil Color: Yellow

- Steam consumption: 900KG/T oil

- Water(soften water): 150Kg/T oil

- Alkali: Acid valuex1-3kg/T oil

- Circulating water cooling water yield: 150M3/H

- Waste bleaching earth oil content: <25~35%

- Refining rate: 1-refining consumption %

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

The list of feedstocks to extract unconventional seed oils is vast, with a wide range of fatty acids profile and with potential applications. This chapter compiles about the methods of seed oil extraction and presents a brief description of the chemical and physical refining routes, which are the most widely used.

Optimization Of Neutralization Parameters In Chemical ..

- Usage: Cooking Oil refinery

- Type: Cooking oil refinery

- Production Capacity: 1T~10T/D

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): depend on capacity

- Weight: according to capacity

- Item: Cooking oil refinery

- Application: various crude oil like Cooking oil

- Operating ways: safe and simple

- Residual oil in cake: low

- Oil grade: high

- Brand: Qi'e

- Refining technics: batch refining and semi-continuous

- Moisture and volatile: 0.08%

The refining process was conducted according to the chemical refining process using optimized parameters in each stage of the refining process specifically for kenaf seed oil that reported in the

reserves of hydrocarbons in the form of crude oil and gas [4]. Most of Malaysia‘s oil reserves are located at the Malay basin and is the third highest in the Asia-Pacific region. The total oil production in Malaysia was 716,000 barrels per day (bbl/d) in 2010 [3]. Over the years, demand for chemical products in Malaysia has been

Samsung E&Amp;A Wins $955 Million Contract For A Biorefinery

- Usage: JOJOBA OIL REFINERY

- Type: Cooking Oil Refinery Machine

- Production Capacity: 10TPD-1000TPD

- Voltage: 220V/380V/420V

- Power(W): 20kwh/h

- Dimension(L*W*H): 20000mm*40000mm*16000mm

- Weight: 20tons to 1000tons

- Machinery type: jojoba seed oil refining plant

- Manufacturer: Factory

- Manufacturing experience: 35years

- Refining type: Physical refining or Chemical refining

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Refining rate: 95%

- Solvent in the oil: cannot be tested

- Water supply system: ciculated water use

- Steam generate: Steam Boiler(coal, wood, gas as fuel)

- Electrical apparatus element: Simens brand, Alfalafa brand

Samung E&A E&A announced that it had received a Letter of Award (LoA) for the EPCC (Engineering, Procurement, Construction and Commissioning) work of Bio-Refinery Project in Malaysia from Enilive S.p.A (Enilive), on behalf of a joint venture consisting of Petronas Mobility Lestari Sdn. Bhd. (PMLSB), a subsidiary of Petronas; Enilive, and

Refining Of Palm Kernel Oil Afe Babalola University

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 10-1000TPD

- Voltage: 220V/380V

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Brand: BEST

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Advantage: Energy Saving;Simple Operation

- Feature: High Output

- Function: Refining/press Cooking Oil

- Color: as requirement

This work studied the refining of crude palm kernel oil derived from the kernels within the nut of a palm fruit. This research project was aimed at reducing the non-glycerides present in oil in their crude form using an alkali method of refining. The crude palm kernel oil was first washed with distilled water by

- Will Malaysia invest $27 billion in a petrochemical project?

- Petroliam Nasional Bhd., Malaysia’s state oil and gas company, will proceed with a plan to invest in a $27 billion refining and petrochemicals project in the southern Johor state bordering Singapore.

- Is Petronas a petrochemical hub in Southeast Asia?

- The country aims to become a petroleum refining and petrochemical hub in Southeast Asia, and state-owned Petronas is leading the way in promoting the petroleum refining and petrochemical complex project (RAPID) to develop an integrated production system from petroleum refining to chemical products.

- What happened to Malaysia's oil refining capacity in 2021?

- Malaysia's oil refining capacity has remained mostly flat, but expanded to 955,000 barrels per day in 2021. This was due to the startup of oil refining facilities as part of RAPID, which remained at the same level in 2022 (Figure 1). Refining throughput declined year-on-year in 2020 during the Corona disaster, but has since picked up.

- Will Malaysia turn Pengerang into an oil and gas hub?

- The project is poised for its refinery startup by early 2019, it said. The latest decision may help a push by Malaysia to turn the fishing town of Pengerang into an oil and gas hub. It comes after Taiwan’s Kuokuang Petrochemical Technology Co. in December ended a plan to build a $12 billion petrochemicals project in the same area.

- Why is Petronas acquiring a biorefinery near Pic?

- To be located adjacent to PETRONAS’ existing integrated refinery and petrochemical facilities, the biorefinery will be able to leverage the company’s integrated value chain as well as existing utilities and facilities in PIC.

- What is Kertih petrochemical industry?

- petrochemicals production and crude oil refining in nearby Paka. As an industry specific development, Kertih’s transformation from a quiet and sleepy fishing village to a top-notch petrochemical hub was finally completed with the set-up of the PETRONAS Petroleum Industry Complex (P