Processing canola seed into oil and meal in Canada

- Usage: Edible Oil

- Capacity: 1TPD-1000TPD

- Voltage: 380V/50HZ

- Power (W): 15KW

- Dimension (L*W*H): 1700*1100*1600mm

- Weight: 1200kg

- Certification: ISO

- Raw material : Vegetable seed

- Name: Oil equipment product line

- Color: Oil equipment product line according to your requirements

- Material: stainless steel carbon and stainless steel

- Application: cooking oil making machine

- Advantage: Oil equipment product line

- Warranty: 12 months

- Feature: Oilfield equipment product line

- Character: Oilfield equipment product line

Solvent extraction. To remove the remaining oil, the presscake is put into an extractor and saturated with a solvent called hexane. The solvent percolates through the cake and carries nearly all of the remaining oil away. The hexane is then removed from the oil and solids, reused and recycled. Further oil refining and processing

This study exposed high-oleic rapeseed oil (HORO) to different pretreatment (microwave or roasting) and processing methods to investigate (cold pressing, hexane extraction, subcritical butane

Soybean Solvent Extraction Plant Oil Expeller and Oil Refinery Machine

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 550 kg/h

- Voltage: 220 V/380 V

- Power : 2.5 kw

- Dimension (L*W*H): 900*850*1550

- Weight: 880kg

- Certification: ISO CE SGS

- cold jojoba oil presser machine: Hydraulic cooking oil extraction pressing machine

- Material: 316 stainless steel

- Pressing tube diameter: 230mm

- Cake oil rate: 6%

- HS CODE: 8479200000

- Multipurpose: yes

- Filter oil: 2

- Color: Customer requirements

- Raw material: Sunflower

- Furniture: Yes

Soya Solvent Extraction Process. Prepared Soya flakes/soya collets from preparatory section is carried by Redler Conveyor and fed to Extractor Either through rotary valve or Plug O Seal to extractor feed hopper incorporated with high and low level arrangement to ensure proper level of material filled in the Hope and seal for the system.

Commercial Processing of Canola and Rapeseed: Crushing and Oil Extraction Ernie H. Unger INTRODUCTION Since the development of canola, its processing in Canada has increased to the point where domestic crushing of canola seed accounts for approximately 38% of all canoIa grown in Canada from 1978 to 1988. In order to ensure that quality canola

Shea Butter Extraction Plant Oil Expeller and Oil Refinery Machine

- Usage: Edible Oil

- Capacity: 20KG/H

- Voltage: 180V-240V

- Dimension (L*W*H): 70*45*65CM

- Weight: 72 KG

- Main components: Motor

- Oil material: Stainless steel oil press machine

- Advantage: use easy, energy saving, simple

- Keep working:: 12 hours

- Shelf life:: 8-10 years

- >Use for: cotton seed, sunflower, soybean, rapeseed, canloa, peanut, etc...

- Keyword: cocoa oil pressing machine

- Function: Oil extraction machine Oil pressing machine

- Application: Commercial Use Screw Oil Press Machine

Shea butter is a vegetable fat extracted from kernels of the shea tree. The shea tree grows in the so-called shea belt, which includes roughly 21 countries: Benin, Burkina Faso, Cameroon, Central African Republic, Chad, Ethiopia, Eritrea, Ghana, Guinea-Bissau, Ivory Coast, Mali, Niger, Nigeria, Senegal, Sierra Leone, South Sudan, Sudan, Togo, Uganda, the Democratic Republic of the Congo, Kenya

Discover the comprehensive process of extracting vegetable oil from plants, from selecting the right plant sources to refining and storing the oil. Learn about the health benefits and environmental impact of this essential process, and explore future trends in oil extraction technology. This guide covers everything you need to know about vegetable oil extraction.

Improving Oil Extraction from Canola Seeds by Conventional ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Voltage: 220V/380V

- Power (W): 1.5 kW

- Dimension (L*W*H)): 900*850*1550mm

- Weight: 1000KG

- Certification: ISO9001/BV/CE

- Name: hot hydraulic oil squeezing equipment

- Material: stainless steel

- Capacity: 350-7000kg/h

- Warranty: One year

- Function: oilseed press

- Item: Vertical oil press

- certificate: ISO9001/BV/CE

- Raw material: Vegetable Seed

- Quality: Superior International

- Package: Wooden box

This manuscript provides a review of the conventional canola oil extraction process and the In preparation for solvent extraction, the canola cake is A typical canola oil processing plant

Extraction, nutrition, functionality and commercial ..

- Usage: Edible Oil

- Voltage: 220V/380V

- Power (W): 15kw

- Dimension (L*W*H): 1700 *1300*1600

- Weight: 1200kg

- Certification: ISO9001

- Product name: Cooking extruder machine

- Capacity: 250-400kg/h

- Size : 2200x1600x2150 mm

- power: 15w

- staff requirement: 2-3 people

- space requirement: 40-60 square meters

- Transmission ratio: 15/38x19/48=1

- Vacuum pump: Y100L1-4-2.2KW

- Heater: 3.8KW

- Authentication: ISO9001

Oilseeds are the most popular plant protein sources, owing to their widespread cultivation production. Canola/Rapeseed is the second most cultivated oilseed worldwide, after soybean, with an annual production of 19.4 million metric tons in Canada, the world's largest producer, in 2020/2021 (Canola Council of Canada, 2021).

- Which country produces the most canola seed?

- The largest producer of Canola seed is Canada followed by China, India, France, Pakistan, Germany and Australia. Rapeseed oil third largest source of edible oil after soya bean oil and Palm Oil. Europe alone contributes six million tons to the world market.

- How is canola oil extracted?

- Canola oil is extracted using two main methods: Mechanical Press and Solvent Extraction. In the Mechanical Press method, Canola oilseeds are pressed in a series of Screw Presses / Expellers. This process does not use chemicals and leaves approximately 5-7% oil in the residual Cake/Meal.

- Which countries produce canola oil seeds?

- The major producers of canola oil seeds are the European Union, Canada, China, and India. The European Union and Canada are among the leading producers, and the Canola (and Rapeseed) oil is the 3rd leading source of vegetable oil, after soybean and palm oil.

- What is the process for canola seed processing?

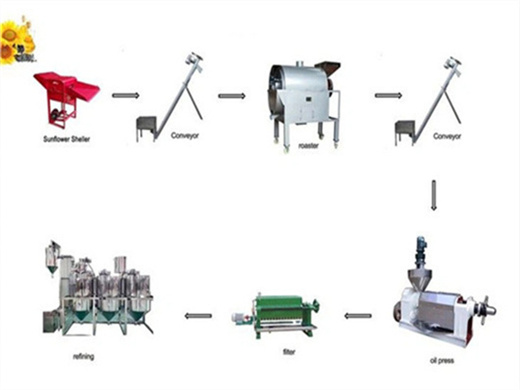

- To process canola seeds, we need basic equipment including a Seed Cleaner, Seed Cooker/Kettle, Oil Press, Filter Press, Steam Boiler, Screw Conveyors, and Bucket Elevators. The process begins with seed cleaning, where canola seeds are separated and cleaned to remove impurities such as dust, metal, and plant stalks.

- Why can't the solvent extraction plant be processed with flakes?

- The Solvent Extraction plant can’t be processed with flakes due to its high oil content. The Oil content are to handled with expander with squeezo matic arrangement. Where 20 % of the oil will be drained and collets containing 25% – 28% oil will be transferred for extraction. The collets is with 35% more porosity than the flakes.

- What is canola oil and rapeseed oil?

- Canola (and rapeseed) oil is the third leading source of vegetable oil, after soybean and palm oil. Canola and rapeseed oil are the same thing, with canola being a variety of rapeseed that has lower erucic acid content and lower glucosinolates. The global production volume of Rapeseed oil has risen steadily over the last several years, and there are still investors who want to enter the Canola Oil Manufacturing industry.