Solvent Extraction Plants BELL Group of Companies

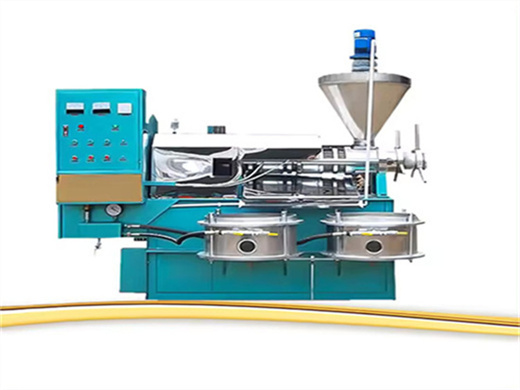

- Usage: Cooking Oil

- Capacity: 100% oil press/expeller

- Voltage: 220 V/380 V/440 V

- Power (W): 15 kw

- Dimension (L*W*H): 5432*2636*2345

- Weight: 850 KG

- Raw material: Oilseeds

- Application: Oil production line

- Capacity: 1-1000 tons/day

- Advantage: Energy saving

- Delivery time: 30-60 days

- Necessary area: Capacity

This innovative technology uses the solvent extraction method, which enables the recovery of residual oil in empty fruit bunches and mesocarp fibres. With existing technology, only up to 95% of oil contained within the mesocarp fibres can be extracted mechanically. However, up to an additional 4% can be further extracted by means of solvent extraction. This

What We Manufacture. we are manufacturers,designers and suppliers of solvent extraction plants,oil refineries,oil milling,oil derivative plants.Agro Process Engineers is supplying plant and machinary in malaysia with extraction technology sdn bhd and in thailand with envitrade engineering co.& extraction technology sdn bhd.as joint ventures Agro Process Engineers supplied more than 150 small

Solvent Extraction Plant Pemac Projects Pvt Ltd

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Voltage: 220V/380V/440V

- Power (W): 10-50kw

- Dimension (L*W*H): 1200*400*900mm3

- Weight: According to cooking oil processing capacity

- Certification: ISO9001/CE/BV

- Keywords: oil mill for sale

- , long-term technical support

- Plam Kernerl Oil Pressing Machine: Available

- Raw Material: Vegetable Seeds

- Factory Area: According to capacity and actual situation

- Residual: Less than 2%

- Technology: Introduce high technology from Malaysia

- Material: The parts are stainless steel

- Product name: oil cooking mill for sale

Oil Expellers / Screw Press left over some oil in the cake which is usually extracted in Solvent Extraction Plant. In the solvent Extraction plant, Maximum oil from the cake/Flakes is extracted using an organic solvent, typically hexane. The steps involved in this process are: Extractor: These are specialized solvent extraction equipment

The Solvent Extraction Plant, in which oil is extracted from oil-bearing materials by treating it with solvent having low boiling point. Solvent Extraction Plant Manufacturer and exporter of solvent extraction plants, solvent extraction plant exporter, solvent extraction plant manufacturer, continuous solvent extraction plants.

Mecpro Heavy Engineering Limited

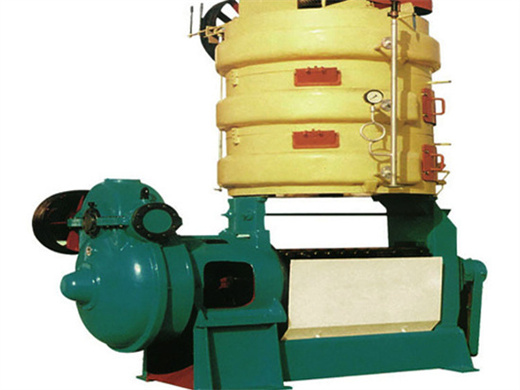

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 1-600t/d

- Voltage: 220V, 380V

- Power (W): 550 kW

- Dimension (L*W*H): according to customer

- Weight: according to customer

- Certification: ISO&CE&BV

- certificate: ISO9001

- Bank credit rating: AAA

- Capacity: 1t-500t

- Material raw material: Vegetable Seed

- final product: cooking oil

- texture: stainless steel and carbon steel

- color: according to client

- warranty: 1 year

- lifespan: 50 years

- after-sales service: design workshop | installation | training

The losses of solvent observed that during continuous operation out of the total hexane losses, 35% are through vent air, 40% through desolventizing toaster, 5% through oil, and 20% through leakages. The vent air purification system will support these losses up to 95% and the solvent extraction hexane loss will be reduced up to below 0.9 kg/MT.

The plant material is treated with boiling solvent and hence is a hot extraction process. The solvent vapor is recycled by a condenser fitted on top of the container, preferentially a round bottomed flask. Hot Continuous Extraction (Soxhlet): It is named after ‘Franz Ritter von Soxhlet’, a German agricultural chemist.

Solvent Extraction Plant Balaji Engineering

- Usage: Cooking Oil

- Capacity: 300 KG/H

- Dimension (L*W*H): 2*1.2*2.8 m

- Weight: 900 kg

- Main components: motor, pump

- Oil type: cooking oil

- Name: Type 125 hot and cold oil pressing machine

- Model: JFD-125D-PO

- Size: 2*1.2*2.8m

- Capacity: 300kg/h

- Range Application: Sesd Plant Types

- Features: High performance dual-purpose hot and cold

- Service after warranty: online support

- Service location Local: Brazil

- After-sales service provided: free spare parts, online support

The extraction plant comprises of Extraction, De-solventizer Toaster, a Distillation System and a Solvent recovery system. The extractor enables extraction of the oil from the cake, Distillation system enables to separate oil from miscella, Recovery group recovers the evaporated hexane, Desolventizer evaporates the hexane from de-oiled cake and toasts the meal to maintain inherent nutrients

Solvent Extraction Plant Shreeji Expeller

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Voltage: 220V/380V

- Power (W): 2.2KW

- Dimension (L*W*H): depends on capacity

- Weight: depends on capacity

- Production process: degumming deacidification discoloration deodorization

- Raw material: many types of crude oil

- Soften water: 150 kg /T of oil

- Phosphoric acid: 2~3 kg/T of oil

- Earth bleaching Consumption: 80 -500KG/T Oil Supplier Steel material: Stainless steel or al carbon

Preparation is the process of properly preparing seeds for extraction of oil either by solvent or mechanical method. While a particular seed may contain from 20 % 50 % oil, the oil is tightly bound within the cell & mechanical action must be taken to either forcefully remove the oil or to make the oil accessible to subsequent solvent extraction.

- What is palm fibre oil extraction plant?

- Palm Fibre Oil Extraction Plant, a plant designed and equipped to extract the residual oil from palm-pressed fibre by means of solvent. A food grade solvent known as hexane is used to extract the remaining 5% – 6% of residual crude palm oil (CPO) available in palm-pressed fibre, thereby enhancing oil extraction rate (OER) by 0.5%.

- What is solvent extraction?

- Solvent extraction is a continuous process that uses edible grade hexane as a solvent and non-edible grade with a non- flammable solvent. Mecpro has invested for years in research and development for improving the technology used in Solvent Extraction Plants.

- What is palm kernel oil extraction?

- A food grade solvent known as hexane is used to extract the remaining 5% – 6% of residual crude palm oil (CPO) available in palm-pressed fibre, thereby enhancing oil extraction rate (OER) by 0.5%. Palm Kernel Oil Extraction (PKOE) Plant, is designed to extract the oil from kernel cake by means of solvent. This shall extract an additional 3% PKO.

- Why is a solvent extraction plant important?

- The design and layout of the solvent extraction plant ensure the easy operation, maintenance, and lubrication of the plant by the operators. It also helps for the smooth running of the plant. Automation in the process ensures consistency in the process and quality of both product and by-product with reduced utility consumption.

- What is mesocarp extraction technology?

- This innovative technology uses the solvent extraction method, which enables the recovery of residual oil in empty fruit bunches and mesocarp fibres. With existing technology, only up to 95% of oil contained within the mesocarp fibres can be extracted mechanically.

- How to filter miscella oil?

- The miscella will be filtered in a filter cloth using self-wash filtration system before entering into distillation process. It will prevent the sediments entering into the distillation which will corrode the equipment and increase the yearly maintenance and deteriorate the oil.