Techno-Economic Analysis of Extruding-Expelling of

- Usage: oil press machine

- Production Capacity: 100TPD

- Voltage: 220V

- Dimension(L*W*H): 1120*320*850mm

- Weight: 80 KG

- Core Components: Motor

- Oil type: Soybean Oil

- Product name: oil press machine

- capacity: 30kg/h raw materials

- control mode: Cold And Hot Press

- type: screw oil press machine

- Packing size: 112X32X85 cm

- Gross weight: 92 kg

- Work time: keep working 24 hours

- suit for: Soybean etc..

- material: stainless steel

- After-sales Service Provided: Free spare parts, Video technical support, Online support

Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%. Soybean oil and soybean meal contributed about 25% and 75% of total revenues, respectively.

Degummed oil is dried in a vacuum dryer after degumming and should not exceed 0.1% moisture. Storage tanks of soybean oil at extraction plants, or terminals, are cylindrical and of mild steel construction. This chapter further discusses the overland transport and water transportation of soybean oil.

Soybean Oil Processing Machine

- Usage: Soybean oil

- Type: Soybean pomace oil solvent extraction meal

- Production Capacity: high

- Voltage: 220V, 380V, or other

- Power(W): depend on the capacity

- Dimension(L*W*H): depend on the capacity

- Weight: depend on the capacity

- color: depend on the clients' requirements

- capacity: based on the need of clients

- Residual oil in meal: ≤ 1%

- Solvent consumption: ≤ 2Kg/T (No.6 solvent oil)

- Crude oil moisture and volatile matter: ≤ 0.30%

- Power consumption: ≤ 15KWh/T

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Residual solvent in finished meal: ≤300PPM (qualified detonated experiment)

If your processing capacity is relatively small, QIYI Machinery recommends that you configure a rolling caldron fry seed machine, screw oil press machine and plate frame filters, which can process 1-10 tons of soybean oil raw materials per day, which is suitable for the daily production needs of small oil press mill.But if your processing

New environmentally friendly methods for extracting vegetable oils are in development, with a focus on pressurized liquid extraction (PLE) in an intermittent process. Ethanol, a renewable and generally recognized as safe (GRAS) solvent, is gaining prominence in this process. It is crucial for these methods to maintain the physicochemical characteristics of the extracted oils and be

Whole soybean protein extraction machine

- Usage: Canned Food

- Type: Autoclave

- Voltage: 380V

- Power(W): 39kw

- Weight: 200kg

- Dimension(L*W*H): 1500*900*1900mm

- Warranty: 1 Year

- Item: mushroom autoclave

- Material: Stainless Steel 304

- Application: glass jars, canned food etc

- Control system: automatic

- Sterilizing way: Hot Steam

- Function: High Temperature High Pressure Sterilizing

- Working Quality: Safe

- Design temperature: 147 Degree Centigrade

- Capacity: 120-150kg

- Processing Types: mushroom autoclave

Within industry, aqueous extract from whole soybeans is commonly used for making consumer products containing both soy protein and soybean oil, and this has been the focus of this review. Key extraction process parameters are presented and challenges of each extraction step are given for the whole soybean extraction process.

In the profitability analysis of the soybean oil extraction process, the total capital investments of extruding-expelling process, hexane extraction, and EAEP are 26.6, 41.0, and 7.6 million dollars (2015 price) based on 30.8, 22.4, and 0.1 million kg of annual soybean oil production respectively.

Soybean Oil Extraction and Processing Springer

- Usage: Soybean Oil

- Type: oil refinery qie, russian oil refinery for sale

- Production Capacity: 10TPD-500TPD

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Color: Silver

- Production Material: Carbon steel, stainless steel

- Raw material: Soybean

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical principle

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

dehulling process to remove soy meats (cotyledons), typically including a second? ary aspiration. However, fines are included with the meats extraction to maximize extraction yield, even though they may create solvent filtration prob? lems during oil extraction. The soy cotyledon contains about 20% oil, whereas the hull has negligible oil

Soybean Oil Extraction and Processing Machine

- Usage: Soybean OIL, All kinds of oil seeds

- Type: Soybean Oil Press Machine

- Production Capacity: 80-100kg/h

- Voltage: 220v

- Dimension(L*W*H): 1600x1100x1550mm

- Weight: 780 KG

- Core Components: Motor

- Oil type: Soybean Oil

- Spiral diameter: 80mm

- Spiral speed: 35r/min

- Chamber inside diameter: 82mm

However, according to Dutton (1981) in the early 1940s, soybean oil was considered a poor quality oil, not suitable for food use, and more appropriate for use in industrial paints. It was first used in margarine in World War II due to the shortages of other fats and oils, but its use was limited to 30% of the product.

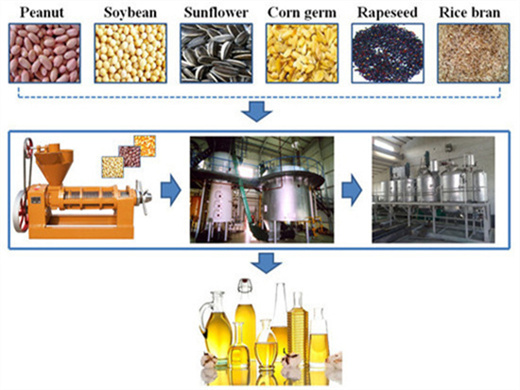

- How is soybean processed?

- Modern soybean processing starts with solvent extraction to obtain crude oil and defatted meal. Most defatted meal is used for animal feed and only a small portion is further processed into different types of soy protein products for human consumption (see Chapter 8). Crude oil contains variable amounts of nontriglyceride materials.

- Can two-stage extruding-expelling process improve soybean oil yield?

- To examine the viability of this improved two-stage extruding-expelling process, techno-economic analysis was performed by using SuperPro Designer for simulation of the soybean extruding-expelling process. Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%.

- How is oil extracted from soy flakes?

- During solvent extraction oil is removed from the soy flakes by an organic solvent to form an oil/solvent mixture called a miscella. The oil is recovered from the miscella by removing the solvent by steam stripping. Most commercial oil extraction is currently by hexane extraction, but other solvents have been considered.

- How hexane is used to extract soybean oil?

- However, efforts have been made to reduce the costs (Reverchon and Osseo 1994). Solvent extraction of soybeans is a diffusion process in which the solvent (hexane) selectively dissolves miscible oil components. During extraction, hexane solubi lizes soy oil from cotyledon lipid bodies in soy flakes rapidly, as soon as it enters the lipid body.

- What are the sources of wastewater from soy oil processing?

- 1. Wastewater Control The sources of wastewater from soy oil processing are (I) process wastewater, which has been in contact with oil, (2) noncontact cooling water that is uncontami nated because it has been circulated in pipes, and (3) rainwater runoff, which may have been in contact with contaminated areas (Smallwood 1995).

- How many tons a day does a soybean extraction plant remove?

- In addition, for grade 2 soybeans, which may contain up to 2% foreign matter, an extraction plant processing 1000 tons daily will remove as much as 20 tons of trash (Snyder and Kwon 1987). Moore (1983) described the cleaning apparatus used to separate foreign materi als (Fig. 6.2). Soybeans are distributed over a two-deck screen sizer.