Evaluation of the parameters affecting the solvent Extraction Machine

- Usage: processing Soybeans

- Production Capacity: according to the capacity

- Voltage: 220v,380v,440v

- Power(W): according to the capacity

- Dimension(L*W*H): 430*230*350

- Weight: 1050 KG

- raw materials: fresh Soybean

- texture: stainless steel,carbon steel

- package: wooden case special for Soybean oil machine

- other materials: Soybean Oil ,Soybean

- using popular area: Srillanka, Malaysia,Phillipine,Nigeria,America tropical area

- main business: South East Asia,Middle America,West Africa

- using life: more than 15 years

- Material: Stainless Steel 304

method. The methods by which a particular oil seeds are extracted depend on the type of seed, the seed characteristics and the oil content of the seed, (Iwe 2003, FAO 1992, and Lawson 1999). Seeds such as soybean seed with low oil content are better extracted using solvent extraction method. Most modern oil extraction machine industries

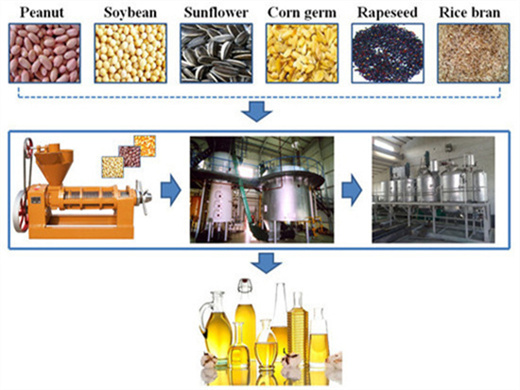

Crude soybean oil needs to be refined before it can be sold or eaten. Soybean Oil Extraction Technology illustration. Usually, when the processing capacity of oilseeds is more than 20 tons/day, the extraction methods can be selected to produce soybean oil, which can reduce the production cost of soybean oil and obtain more profits.

Soybean oil production process in a edible oil plant

- Usage: Soybean Oil, Soybean /Soybean oil extraction machine

- Automatic Grade: Automatic, Automatic

- Production Capacity: 200kg/h

- Voltage: 220V

- Dimension(L*W*H): 1120*320*850mm

- Weight: 80 KG

- Core Components: Motor, PLC

- Oil type: Soybean Oil

- Product name: 2000 kg/h Soybean oil press machine price in zambia

- Product Product function: extraction oil from Soybean

- Application: Soybean,

- Product item: prickly pear seed /Soybean oil extraction machine

- Advantage: Simple Operation

- Capacity: 20-250KG/h

A Step-by-Step guide For Edible Oil Production From Soybean Seeds Riyaz Tunvar Riyaz is the Sales and Marketing Director at N&T Engitech Pvt. Ltd., a leading manufacturer and supplier of complete edible oil plants and machinery.

Then, the request of response surface methodology to optimize oil extraction from soybean seed has been successfully confirmed at optimum parameters: temperature 70, solvent to solid ratio 10

Effect of feed particle size and solvent flow rate on soybean

- Usage: Soybean Oil

- Type: Vegetable Seed Oil Machine

- Production Capacity: 10T-100T/D

- Voltage: 220V/380V

- Power(W): According to the actual situation

- Dimension(L*W*H): According to the actual situation

- Weight: According to the actual situation

- Product name: Soybean Oil Press Machine

- Residual oil: Less than 1%

- Machinery for making crude soy bean oil: Carbon steel Q235 and stainless steel SS304/316

- Advantage: Design, manufacturing,installation and commissioning,training

The direct solvent extraction method is employed for low oil-bearing (< 30% oil) materials, and soybean oil is the largest direct solvent-extracted vegetable oil. The very high oil yield, lower boiling point (66.6 °C to 68.9 °C), low latent heat of vaporisation (335 kJ/kg), low corrosion and an acceptable odour for the defatted meal makes

It was stored in a refrigerator at 4 °C, so that its enzymatic activity did not change significantly during the period of the study. Soxhlet apparatus (Make: Perfit India, Gupta Scientific Industries Model: HT 1043) was used to measure the oil content of seed. Soybean oil yield obtained by solvent extraction was 18.42 g per 100 g milled soybean.

Effect of Solvent Extraction Parameters on the Recovery of

- Usage: Soybean Oil, Cooking Oil

- Type: Soybean Oil Press Machine

- Production Capacity: above 98%

- Voltage: 220V/110V

- Dimension(L*W*H): 42*16*30 cm

- Weight: 11kg

- Core Components: Motor, Gearbox

- Product name: small oil press machine

- Control model: full automatic

- Squeezing type: screw type

- Function: Oil Pressing

- Production: 3-5(kg/h)

- used for: Soybean,beans,Soybean etc

- Material: SS materials body

- Certificaiton: CE,ROHS

- Machine color: silver

- keep working: 12 hours

Seed flakes of thicknesses between 0.2 and 0.3 mm were reported to result in higher oil extraction rates, while a decrease in flake thickness from 5 to 0.5 mm resulted in yield increases in the case of oil extraction from soybean, cottonseed and sunflower [30, 31, 35?37].

Extraction and Characterization of Soybean Oil Based Bio

- Usage: edible oil

- Type: Vegetable Seed Oil Machine

- Production Capacity: 80kg/h, 500kg/h, 100kg/h

- Voltage: 220V/380V/440V

- Power(W): 11KW

- Dimension(L*W*H): 1.5*2.6*3.6M

- Weight: 0.5-10T

- Product name: Soybean bean oil screw oil presser

- Raw material: Soybean

- Application: all kinds of oil seeds

- Function: get grade 1 cooking oil

- Feature: Multifunction High Efficient

- Model: LD88

- Quality: 15 years service time

- Advantage: 35 years experience

- Color: Nippon

shown in Table 1. 4. Discussion The proximate analysis of raw soybean seed is given in Table 1 which shows that the raw soybean seed contains higher percentage of volatile matter and lesser amount of moisture and ash contents. In Table 2, the percentage of oil content, 18.25%, shows a variation from the report

- What is modern soybean oil?

- Modern soy oil is a stable high quality triglyceride ingredient used widely in commercial processed foods. It is without other lipid contaminants and available at a reasonable cost. Modern soybean processing starts with solvent extraction to obtain crude oil and defatted meal.

- How hexane is used to extract oil from soybeans?

- Hexane is extensively used for oil extraction from soybeans and and low greasy residual effects (Anil Seth, 200 7). In the solvent extraction process, Soxhlet extraction using normal hexane as solvent h as been used. Extraction using solvent has several advantages. It give higher yield and less turbid oil than mechanical extraction, and

- How is oil extracted from soy flakes?

- During solvent extraction oil is removed from the soy flakes by an organic solvent to form an oil/solvent mixture called a miscella. The oil is recovered from the miscella by removing the solvent by steam stripping. Most commercial oil extraction is currently by hexane extraction, but other solvents have been considered.

- How is soybean seed oil extracted from (Keta & billo19)?

- The soybean seed oil was extracted from (Keta and Billo19)variety using normal hexane by soxhlet device. Concluded the aid of a Design Expert and using the central composite design of the response surface methodology, the experiment was 27 twenty-seven but by composite reduced which has the same value and runs.

- How is soybean processed?

- Modern soybean processing starts with solvent extraction to obtain crude oil and defatted meal. Most defatted meal is used for animal feed and only a small portion is further processed into different types of soy protein products for human consumption (see Chapter 8). Crude oil contains variable amounts of nontriglyceride materials.

- Why is the soybean price a critical factor for hexane extraction?

- Material cost takes up about 44% of total operating costs in a facility producing 4 million kg of soybean oil and increases to over 90% of total operating costs in 173.22 and 415.73 million kg of soybean oil production facilities. Therefore, the soybean price is concluded as a critical factor for the hexane extraction process. 3.2.2. Utility costs