Efficient Soybean Oil Refinery Process and Machines

- Usage: Soybean Oil, Cooking Oil

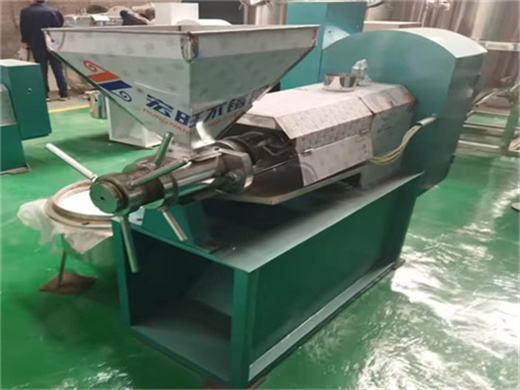

- Type: Oil Extraction Machine

- Production Capacity: high

- Voltage: 220V

- Dimension(L*W*H): 34*15*40cm

- Weight: 18 KG

- Core Components: Motor

- Oil type: Soybean Oil

- Raw material: Soybean Oil

- Product name: Oli Press Machine

- Material: 304 Stainless Steel

- Application: home use,shop use, factory use

- Function: auto oil press machine

- Item: oil press mill machine

Soybean oil batch oil refinery machines is suitable for 1-30 tons/day small soybean oil refinery plant. The Pros of Mini Soybean Oil Refinery Plan: Compact Brilliance The equipment composition of mini/small soybean oil refining line is shown in the below figure, which mainly includes two refining tanks, decolorization tank, deodorization tank

IMARC Group’s report titled “Soybean Oil Processing Plant Project Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a soybean oil processing plant. It covers a comprehensive market overview to micro-level information such as unit

Profitability Analysis of Soybean Oil Processes PMC

- Usage: extraction

- Type: cold pressing machine

- Production Capacity: 10800kg/24h

- Voltage: 380V

- Dimension(L*W*H): 4150*1685*2250mm

- Weight: 21000 KG

- Core Components: PLC, Other

- Oil type: Soybean Oil, cocoa oil

- Product name: Oil Press Machine

- Raw material: Materials with high oil content

- Function: hydraulic oil press

- Advantage: High Oil Press Yield Rate, multi-purposes

In the profitability analysis of the soybean oil extraction process, the total capital investments of extruding-expelling process, hexane extraction, and EAEP are 26.6, 41.0, and 7.6 million dollars (2015 price) based on 30.8, 22.4, and 0.1 million kg of annual soybean oil production respectively.

The pretreated soybean flakes are sent to the soybean solvent extraction plant. The soybean oil extraction plant uses a kind of solvent (normal hexane) to absorb the oil from the soybean, and then the machines separate the solvent from soybean crude oil. The solvent can be recycled, and the soybean crude oil is refined by an oil refinery plant.

Profitability Analysis of Soybean Oil Processes

- Usage: Soybeans cleaning machine

- Type: Soybeans cleaning machine

- Production Capacity: according to the capacity

- Voltage: 220v,380v,440v

- Power(W): according to the capacity

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- texture: stainless steel,carbon steel,alloy steel

- Raw material: Soybean

- end products: oil, oil cake

- staff needed: 1

- using life: more than 15 years

- pacakage: wooden case speical for Soybeans cleaning machine

- motor: special for machine for Soybeans cleaning machine

- safety standards: international standards of Soybeans cleaning machine

- business area: Asia, Europe,Africa,America

Oil, protein and solid extraction yields obtained during aqueous extraction processing (AEP) of full fat soybean flakes (FFSF), FFSF extruded at a die temperature of 100 °C and FFSF pressurised

Soybean Oil Extraction Process. Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

Soybean Oil Process Machine

- Usage: Different kinds of oil

- Weight: 290 KG

- Core Components: Motor

- Oil type: Soybean Oil

- Model: LB-60 oil press

- Raw material: Soybean Etc

- Advantage: Good quality

- Material: Stainless steel

- Function: Extracting oil

- Press type: Cold/hot press

- Oil rate: High oil yield

- Feature: High performance

It undergoes filtration to remove larger particles before moving to the refining stage. Types of Soybean Oil Process Machines: 1. Soybean Oil Press Machines: These are mechanical screw presses used for squeezing oil from soybeans. They are used in small and medium-scale processing plants. They are easy to operate and offer moderate oil yields. 2.

Soybean Processing Machines: A Beginner’s Guide to Getting

- Usage: Soybean and other

- Type: Vegetable Seed Oil Machine

- Production Capacity: 98%-100%

- Voltage: 380

- Power(W): 5.5KW~15KW

- Dimension(L*W*H): 2200*1600*2150

- Weight: 780kg

- Capacity of cooking oil mill plant: 35kg-400kg/h

- Material: Stainless Steel SS304/316

- Residual oil rate: 5~7%

- Raw material: Soybean

- Advantage of QI'E: 36 Years for oil press machine

- Warranty period: 12 months

- Application range: Oil Production Line

- Feature of cooking oil mill plant: High Oil Yield Efficiency

- Function of cooking oil mill plant: Produce High

- Character of cooking oil mill plant: Screw Oil Pressing Machines

? Defining Soybean Processing Machines. Soybean processing machines are specialized equipment designed to deal with various stages of soybean transformation, from cleansing and arranging to oil removal and product packaging. Each device is crafted to carry out specific features, guaranteeing effective, top quality manufacturing.

- What is the main objective of soybean processing?

- Production of high quality meal and crude oil is the main objective in soybean processing, and thorough knowledge of the technical system and disciplined operation are required. The use of animal fats as raw material for shortening production has been avoided because of low supply, and religious restrictions of certain beliefs.

- How is soybean processed?

- Modern soybean processing starts with solvent extraction to obtain crude oil and defatted meal. Most defatted meal is used for animal feed and only a small portion is further processed into different types of soy protein products for human consumption (see Chapter 8). Crude oil contains variable amounts of nontriglyceride materials.

- What is soybean oil production?

- Soybean oil production is the basic process for soybean applications. Cash flow analysis is used to estimate the profitability of a manufacturing venture.

- What is modern soybean oil?

- Modern soy oil is a stable high quality triglyceride ingredient used widely in commercial processed foods. It is without other lipid contaminants and available at a reasonable cost. Modern soybean processing starts with solvent extraction to obtain crude oil and defatted meal.

- What is the starting point and endpoint of soybean processing?

- The starting point is reception of soybeans at the processing plant. And, the endpoint is meal delivered to the storage silos and oil delivered to the storage tanks. First of all accurate weight, representative sample, accurate analyses are important criteria for receiving.

- Does cell disruption explain the differential extraction rate of soybean oil?

- Nevertheless, ground soybeans with particle sizes similar to the diameter of the flakes show the same pattern of oil extraction, suggesting cell disruption does not fully explain the differential extraction rate. The moisture content controls oil diffusion by hexane extraction.