Cotton Seed Delinting Process Machine, Cottonseed Oil Machine

- Usage: Cottonseed Oil

- Type: Cold & Hot Pressing Machine, horizontal screw press

- Production Capacity: 250-400 kg/h

- Voltage: According to customer demand

- Power(W): 21 KW

- Dimension(L*W*H): 2200*1600*2150

- Weight: 1300kg

- Color: White, green

- Production Material: Carbon steel, stainless steel

- Raw material: Cottonseed

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical extruding

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

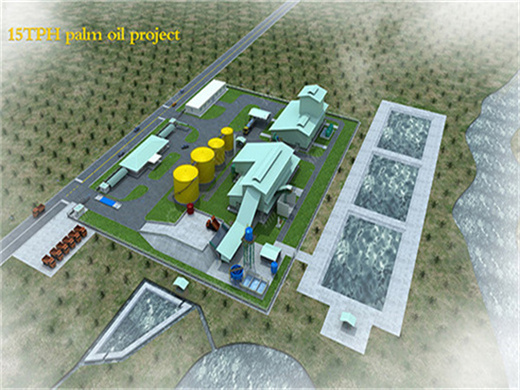

50TPD Palm Oil Refining And Fractionation Project In Cotton Seed Delinting Process Machine Total Lint output ratio:6.5-10kg/h The first output ratio:12.5-17.5kg/h

Cottonseed Oil Processing Machine. Usually, when press the cottonseeds, the cottonseed oil processing machine need be grinded first using raw material, in order to make the pressing temperature of chamber reach 80-120 degree. Then there is oil come out. If there is no heater, it takes about 30 minutes to make the temperature reach the appointed

Cottonseed Oil Extraction Machine Find Cottonseed Oil Processing Machine

- Usage: Cottonseed Oil

- Production Capacity: 100%

- Voltage: 380

- Power(W): 7.5kw

- Dimension(L*W*H): 900*850*1550MM

- Weight: 780kg

- Capacity: 35-550kg/h

- Material: Stainless Steel SS304/316

- Advantage: Simple Operation

- Warranty period: 24 months

- Raw material: Cottonseed

- production cendtion: staff 1 plant 10

- usage: oil press machine

- business type: manufacturer

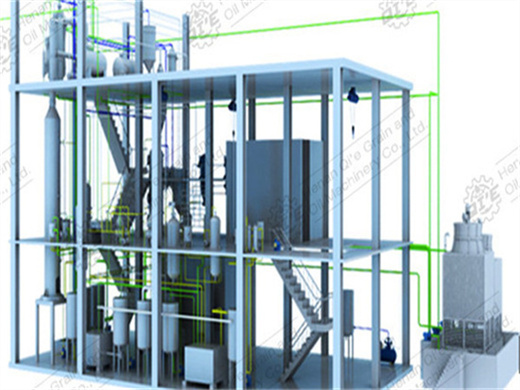

The extracting cottonseed oil enters into classification evaporation and gas stripper after filtration to extract crude cottonseed oil, and finally enters into oil refining plant. The solvent is recycling used through recycling system. Flow Chart of cottonseed oil extraction:

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant it's manufacturing process, world market status and other features.

cotton seed s oil press machine certificate in ndola

- Usage: Cottonseed oil extraction production line

- Production Capacity: 100% Cottonseed oil machine price

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity, according to the capacity

- Weight: Depand on your capacity

- Raw material: Cottonseed

- Application: Oil Pressing

- Common capacity: 1-1000TPD

- Warranty: One Year

- Character: semi-auto, automatic

- Certificate: CE/BV/ISO9001

- Item: Edible Oil Press

cotton seed s oil press machine certificate in ndola . Production Capacity: 100kg/h-10000kg/h; Voltage: 380, 380V; Dimension(L*W*H): 860*680*900mm

Type: fractionation of palm oil on basis of melting points Processing Material: palm oil Capacity: 10-500T/D Major equipment: crystal jar, water-cooled screw chillers, membrane filter press Application: new type oil fractionation technology applicable for palm oil, cottonseed oil Palm oil fractionation Introduction: Palm oil fractionation goes through the control of…

Cottonseed Oil Manufacturing Process and Machinery

- Usage: oil press machine in pakistan

- Type: Cottonseed Oil Press Machine in pakistan

- Production Capacity: 3-130TPD

- Voltage: 380v or according to the local voltage

- Power(W): According to the capacity oil press machine in pakistan

- Dimension(L*W*H): 430*230*350 oil press machine in pakistan

- Weight: 1050 KG oil press machine in pakistan

- Automatic grade: Full automatic

- After sale service: Engineer abroad service

- Cake oil residue: Less than 6%

- Turnkey project: Yes

- Consumption: Low

- Warrenty: 12months

One of the widely used machine used in cottonseed oil manufacturing plant is screw cottonseed oil machine, a type of cottonseed oil machinery. It’s very simple in nature and can be used to extract oil from various seed plants. The screw cottonseed oil press is a mini cottonseed oil machine that can be used for small-scale extraction oil plants.

Cottonseed Oil Processing Plant Extraction Flow

- Type: Cottonseed Oil

- Product Type: Wood Oil

- Processing Type: Cold Pressed

- Packaging: Bulk

- Purity (%): 100

- Volume (L): 120

- Grade: 1

- Use: Cooking

- Usage: Food Industry Oil Refining Industry

- Product name: Industry

- Application: Bakery Products

- Refined Cottonseed oil: Cottonseed oil CP8

Cottonseed Oil Decolorization. The main purpose of bleaching is to remove pigments from cottonseed oil to improve the color and appearance of the oil. First, we need to heat the degummed (or deacidified) cottonseed oil to 110-120°C. Second, add 0.5-1.5% of an adsorbent such as activated carbon or clay.

- How to make cottonseed oil?

- Cottonseed oil production plant can be done in 3 ways: Mechanical screw oil pressing, pre-pressing and solvent extraction and direct solvent extraction. Here, let's talk about the cottonseed oil manufacturing process and related equipment. Cottonseeds that have lint will have to go through the delinting machine to remove the lint.

- What is the oil rate of cotton seed?

- The 18%-22% oil rate is the cottonseed with shell, for your capacity, to get more oil you should dehull the cottonseed before pressing. The oil rate of the cottonseed kernel is 34%-38%. I have send you our cotton seed pictures through email, please advise on cotton seed oil mill factory.

- What products can be derived from a cotton oil mill project?

- The following products can be derived from a cotton oil mill project: cottonseed soap stock, cottonseed oil, cottonseed hull, and cottonseed oil. The following features are highlighted in our cottonseed oil manufacturing plant Project: A high percentage of automated tasks for saving labor.

- Does a cottonseed oil mill plant need a solvent extraction workshop?

- A cottonseed oil mill plant that has a commercial grade is likely to be compatible with solvent extraction, which requires cottonseed cake solvent extraction workshop, crude cottonseed oil refinery workshop, and cotton seeds pretreatment and pre-pressing workshop.

- How to build a top quality cottonseed oil mill plant?

- If you want to build a top quality Cottonseed Oil Mill Plant with or without refning plant, the very first step is to buy high quality oil extraction and refinery machinery - Lesser power consumption, minimum noise during operation and continuous production for better productivity.

- How many tons of cottonseed oil a day?

- To handle 20 tons of cottonseed per day, the solvent extraction method is used with cottonseed oil prepress to take parts of the oil. The machine used for the job has a large capacity and its cake leaves less residual, which makes it easy for the solvent to penetrate. Residual oil can be collected with the use of an oil residue scraper.