Newest 3-Phase Decanter for Avocado and Palm Oil Processing

- Usage: Palm Oil

- Production Capacity: 250-300KG/H

- Voltage: 380V

- Power(W): 3KW

- Dimension(L*W*H): 2000x1200x2500mm

- Weight: 2200kg

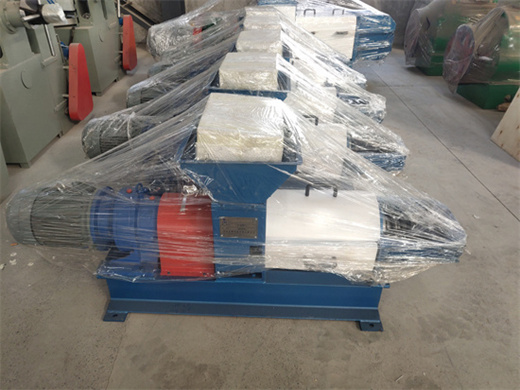

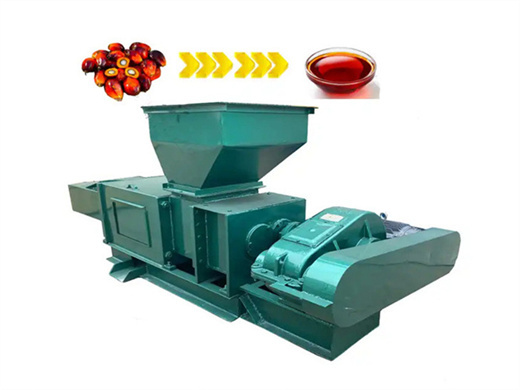

- automatic oil press machine: oil press Palm oil expeller for sale

- Material: 316 Stainless Steel

- Barrel Dia: 40cm

- Cake oil rate: 3%

- Pressure: 35-50mpa

- Multi-purpose: yes

- Advantage: Energy Saving

- Color: Clients' requirements

- Raw material: Palm

- Movable: Yes

Newest 3-Phase Decanter for Avocado and Palm Oil Processing US$35,680.00: 1 sets (MOQ). 24 Hours Hot-Line & Emailed Service: Warranty: 1 Year:

The decanter centrifuge is suitable for solid-phase dewatering, liquid-phase clarification and separation, liquid-liquid-solid three phase separation and size-grading of various suspensions with solid-phase particle sizes of 0.005-15mm, consistency of 1-40% and temperature of ≤ 100°C, esp. for separating the suspensions whose consistency and particle size vary greatly and for which recovery.

DECANTER CENTRIFUGE FOR CRUDE PALM OIL PROCESS

- Usage: Palm Oil

- Type: Oil Press Machine

- Production Capacity: 150-200KG/H,3.5-5T/24H

- Voltage: 380V/220V

- Dimension(L*W*H): 1900*1300*2000mm

- Weight: 9100kg

- Warranty: 1 Year, 1 Year

- Warranty of core components: 2 years

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Other

- Oil type: Palm Oil

- pressing cage heating power: 0.8kw-220v

- Filter air compressor power: 2.2kw-220v

- Main shaft heating power: 1.8kw-220v

- Application: Palm Oil/Palm oil

- machine material: Carbol Steel

The PAWT series 3-phase decanter separates the pressed crude oil mixture that comes from the underflow of the main settling tank into an oil phase, a dry solids cake and virtually oil-free wastewater. The oil phase is sent to a purifier, which polishes the palm oil and reliably removes even extremely small contaminants. The palm oil sludge.

ZK SEPARATION provides various models of palm oil decanter centrifuges, which can efficiently separate and extract palm oil, increase oil recovery, and reduce water consumption and operating costs. Our products have a variety of processing capabilities and application ranges and can be used by palm oil processing enterprises of different sizes.

Centrifuge 3-Phase Separating Decanters Recovery

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, palm oil refining machine

- Production Capacity: 98%

- Voltage: 380V&220V

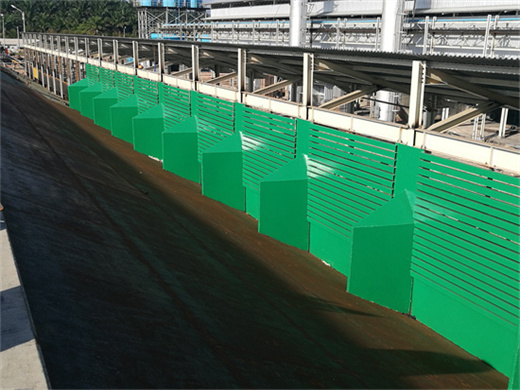

- Dimension(L*W*H): 18m*8m*8m

- Weight: 38 KG

- Warranty: 1 Year

- Key Selling Points: Famous brand motor

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC

- After-sales Service Provided: Engineers available to service machinery overseas

- Materials: Carbon steel Q235 and stainless steel

- Brands: TOP 10 Cereals&Oil Machinery Brand

- Feature: continuous,automatic control

- Price: Negotiation

- power/ton: 32kwh

- steam/ton: 450kg

- water/ton: 300Kg

- Circulation water/ton: 2000Kg

3-Phase decanters separate both, the olive pulp or the palm oil sludge into oil, water and solids. This 3-Phase separation requires a comparably high amount of dilution water. In olive oil production GEA also offers 3-Phase decanters for treating the waste water from the olive oil recovery process.

Industrial Cbd Ethanol Extraction Machine Manufacturing Plant,food & Beverage Shops Manual Top Discharge Production Line Depends $90,000.00-200,000.00 Min. order: 1 set

3 Phase Decanter Centrifuge Tricanter Machine for Crude Oil Processing Machine

- Usage: Palm OIL

- Type: Cold & Hot oil Pressing Machine

- Production Capacity: 5kg-50kg/h

- Voltage: 220V

- Dimension(L*W*H): 52*31*55 cm

- Weight: 45KG

- Warranty: 1 Year

- After-sales Service Provided: Field maintenance and repair service

- Raw material: Palm Kernel

- Application: Palm

- Item: Palm Oil Processing Machine

- Product name: Screw Press Oil Expelle

- Keep Working: 24h

- Used for: Palm Oil Extraction Machinery

Joston Essential Oil Extractor for Eucalyptus Rosemary Sage Oil Solvent Extraction Machine US$8,500.00-12,000.00 / Piece Joston Lab Supercritical CO2 Extraction Machine Miniature Models (1L 5L 10L 20L) for Efficient Plant Essential Oil Evaporation

3 Phase Decanter Centrifuge for Palm Oil Production Line

- Usage: Palm Oil

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 5.5kw

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 1200kg

- Raw material: Palm

- Function: oil press machine

- Application: oil press machine with generator

- Color: alternative

- Advantage: automatic

- Capacity: 100t/d

- Machine type: 6100

- character: LD'E oil press machine with generator

3 Phase Decanter Centrifuge For Palm Oil Production Line Buy Plam Oil Decanter Centrifuge china Decanter Centrifuge Oil Avocado Palm Protein Separator Machine Product on Alibaba.com All categories

- What is a 3-phase decanter?

- 3-Phase decanters separate both, the olive pulp or the palm oil sludge into oil, water and solids. This 3-Phase separation requires a comparably high amount of dilution water. In olive oil production GEA also offers 3-Phase decanters for treating the waste water from the olive oil recovery process.

- How does a palm oil decanter work?

- The PAWT series 3-phase decanter separates the pressed crude oil mixture that comes from the underflow of the main settling tank into an oil phase, a dry solids cake and virtually oil-free wastewater. The oil phase is sent to a purifier, which polishes the palm oil and reliably removes even extremely small contaminants.

- Why do oil mills use 3-phase decanters?

- They reduce the volume of waste water and its COD value and the oil mill gains up to an additional 0.5 percent of oil relative to the quantity of olives processed. When it comes to the recovery of palm oil our 3-Phase decanters are used in the conventional as well as the crude oil process setups.

- How does a 3 phase oil decanter work?

- variety of elements to fine tune and maximize yields. With ANDRITZ decanters, you ity of more than 95%.ADJUSTABLE SKIMMER IN OPERATIONIn a 3-phase decanter, the light phase of the oil is discharged under pressure (1.5 to 2 bar) by means of a skimmer (also named a “pipette”) that can be adjusted at millime

- What is L recovery3-phase decanter mills for palm oil?

- L RECOVERY3-PHASE DECANTER CENTRIFUGES FOR PALM OILPalm oil is one of the most important primary p oducts in the world‘s oil, fat and biofuel markets. The main objective of every mill is to economically separate the crude oil from the

- How Gea decanters help in olive oil production?

- In olive oil production GEA also offers 3-Phase decanters for treating the waste water from the olive oil recovery process. They reduce the volume of waste water and its COD value and the oil mill gains up to an additional 0.5 percent of oil relative to the quantity of olives processed.