Palm Oil Processing Machinery Manufacturer

- Function: stainless steel edible oil refining machine

- Capacity Model: 5~600T/D

- Suitable material: crude oil

- Patent product: Yes

- Patent No.: ISO9001

- Fully automatic: Yes

- Technology support: life time

- Warrenty: one year

- After-sale service: Offering installation and debugging

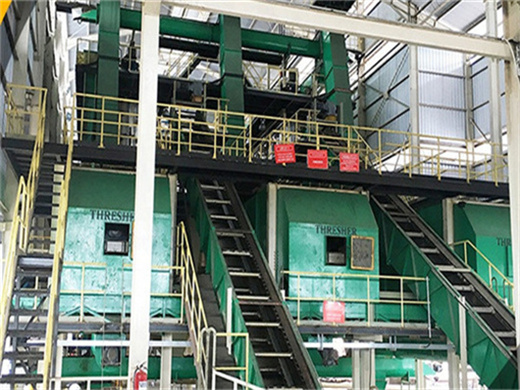

QIYI Machinery mainly engaged in edible oil raw material pretreatment, pressing, solvent extraction, refining, bleaching, dewaxing, deodorizaiton, palm oil and palm kernel oil pressing, CPO Refining and fractionation, etc.

Energy prices: palm oil processing requires a large amount of energy such as electricity and steam, and changes in energy prices will directly affect production costs. Transportation costs: Palm oil production requires transportation from planting bases to processing plants, markets, etc. Transportation costs are also one of the factors that.

Palm Oil Production Process: A Step-By-Step Guide

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 10T-3000T/D

- Voltage: 380V,440V

- Power(W): according to capacity

- Processing: edible oil extracting machine in south africa

- Electric Consumption: 28Kwh/T Oil

- Soften Water:

- Phosphoric Acid:

- Bleaching Earth Consumption:

- Refining Rate:

- Waste Bleaching Earth Oil Content:

- Circulating Water Cooling Water Yield:

- Supplier Type:

- ITEM: edible oil extracting machine in south africa

The Palm Oil Production Column will introduce the details of each process, providing you with the guidance and support you need for your palm oil business. Unveiling Palm Oil Production Process Steps Refining Process-Starting a Palm Oil Refining Plant Cost

The data shows that there are three types of palm oil machines that are more popular in Nigeria: complete palm oil production lines, simple palm oil press lines, and specialized palm oil press machines.

Physical And Chemical Process In Palm Oil Refining Plant

- Usage: Cooking oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 20-2000TPD

- Voltage: 380V

- Power(W): standard

- Dimension(L*W*H): standard

- Weight: standard

- Application: Cookings Oil Production Line

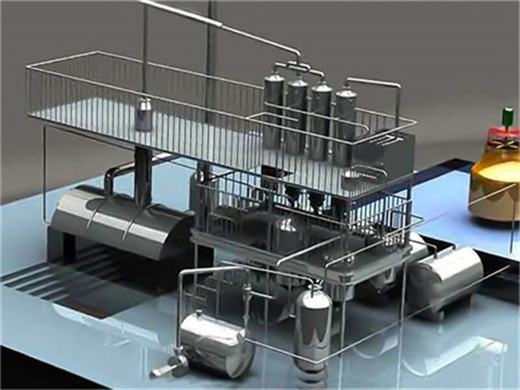

Palm Oil Physical Refining Process. Oil physical refining process, also called as oil steam refining. During the degumming section in the palm oil milling plant, the gum will be removed from palm oil by utilizing phosphoric acid or citric acid. Next to bleaching section, the coloring matter and other metal ions will be absorbed or removed.

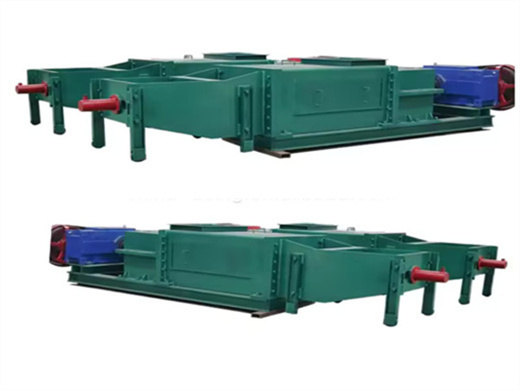

1-5tph complete set palm oil processing machinery is newly and specially designed by Henan HongDe Cereals and Oils Machinery Co.,Ltd engineers. 1-5tph small scale palm oil processing machinery adopts international advanced and mature palm oil extraction technology to extract palm oil.

Rwanda To Boost Local Production Of Edible Oil With Us$10M

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 7.5kw

- Dimension(L*W*H): Based on Oil Press Machine capacity

- Weight: 1200kg

- Product name: Good quality russian oil refinery for sale

- Advantage: Energy Saving

- Warranty period: 12 months

- Application range: Oil -bearing Material

- Function: Refining Vegetable Oil

- Item: Vegetable Oil Refining Machines

- Use for: Vege

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Section: Oil Refinery Machine Section

- Product: National Oil Standard

The global price of palm oil, the most widely consumed edible oil, has been increasing since last year after the Covid-19 lockdowns cut output from plantations in Southeast Asia. Reuters reported on June that Malaysia’s benchmark crude palm oil price touched US$1,007.30 a tonne (Sh108,587) in mid-March, the highest since 2008.

Palm Oil Refining Process Deodorization Process

- Usage: all kinds vegetable seeds crude oil

- Type: Cooking oil refining plant

- Production Capacity: 20-300TPD oil refining machine

- Voltage: 240V or 380V or according to your request

- Power(W): KW

- Dimension(L*W*H): containers

- color: silver

- type: Cooking oil refining plant

- Use:

- description: semi-continuous or full continuous

- steam consumption: 450kg/T oil

- phosphoric acid:

- electric consumption: 28kwh/T oil

- Bleaching earth consumption: 5~50Kg/Toil

- Waste bleaching earth oil content: <35%

- Deodorization loss consumption: ≤0.5%

QIYI Machinery is here to introduce our HOT Sale Small Scale Palm Oil Refinery Machine to you! It is the best palm oil refining equipment for small oil mill. The following is a brief introduction to the refining process and characteristics of small scale palm oil refinery. Small Scale Palm Oil Refinery Machine for Sale

Alibaba offers 657 Coconut Oil Processing Machine Suppliers, and Coconut Oil Processing Machine Manufacturers, Distributors, Factories, Companies. There are 325 OEM, 307 ODM, 108 Self Patent.

Palm Oil Refining Process Deodorization Process. In the palm oil refining process, the deodorization process is a very important step.The palm oil deodorization process is a process of removing odorous substances by steam distillation under high temperature and high vacuum conditions, using the great difference in volatility between odorous substances and triglycerides in oils.

- Why is equipment layout important for palm oil mills in Indonesia?

- In the construction of palm oil mills in Indonesia, a reasonable palm oil factory plant and equipment layout design is crucial for improving production efficiency and operational safety. Proper equipment layout not only affects the ease of maintenance and repair, but also has a profound impact on the construction investment and economic efficiency.

- How to start a palm oil processing plant in Indonesia?

- Establishing a palm oil processing plant in Indonesia is a lucrative opportunity, and a careful understanding of the associated costs is key to success. Key steps include the cost of acquiring suitable land, infrastructure costs, processing machinery costs, and various management and operational costs. Plant Layout and Design:

- How to invest in palm oil processing mills in Indonesia?

- In the business of investing in palm oil processing mills in Indonesia, site selection is a crucial decision. Choosing the right location not only directly affects the factory construction process and the size of the investment, but also has a profound impact on the local economy, environment, agriculture and society.

- What is palm oil refining equipment?

- Palm oil refining equipment includes oil-water separation equipment, deodorization equipment, bleaching equipment, etc. to improve the purity and quality of palm oil. 2. Consider Palm Oil Storage And Packaging Areas

- Who is palm oil mill machinery?

- Palm Oil ABC Machinery is the leading palm oil mill machinery supplier that is integrated with palm oil mill machine manufacturing, mechanical and electrical engineering design, equipment installation and commissioning. We has our own research institute for the development of new products and new product experimental base.

- How to design palm oil mill production equipment layout?

- Palm oil manufacturing equipment layout design should follow the order of the palm oil production process flow, the selected equipment should be reasonably arranged in the workshop to ensure smooth production. Below are some suggestions for general palm oil mill production equipment layout design: