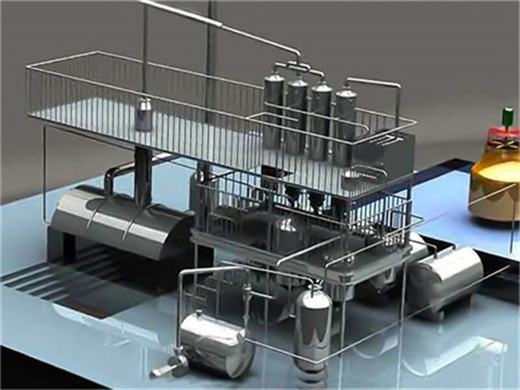

Palm Oil Refinery Equipment Price In Indonesia Palm Oil Production Line Palm Oil Refinery Machine

- Usage: Hot sale machine for refined bleached deodorized Cooking oil

- Type: Hot sale machine for refined bleached deodorized Cooking oil

- Production Capacity: 50T-100T/D

- Voltage: 220V/380V

- Power(W): depend on the capacity

- Item: Hot sale machine for refined bleached deodorized Cooking oil

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- After sale service: Yes

- Brand: LD'e

- Soften Water: 150Kg/T Oil

- Phosphoric Acid: 2~3 kg/T Oil

- Bleaching Earth Consumption: 3-5Kg/T Oil

- Overseas installation: Yes

- Business type: Manufacturer

palm oil refinery equipment Stats. There are total 272 trusted palm oil refinery equipment companies. These include: 82 Manufacturers, 54 Exporters, 27 Wholesalers, 68 Suppliers, 16 Retailers, 8 Buying Houses, 11 Traders, 3 Services, 3 Others, There are 353 palm oil refinery equipment importers and buyers on ExportHub.

Palm Oil Refinery Set Up Cost. The cost to start and operate a palm oil refinery plant covers a lots of aspects. QIYI Machinery, as a reliable and professional manufacturer and supplier for palm oil processing machinery and palm oil refining equipment, will tell you how to calculate the cost of running a palm oil refinery plant.

How Much Does It Cost To Set Up A Palm Oil Production Plant

- Usage: Cooking oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 1-50T/D

- Voltage: 380V /440V or the local voltage

- Power(W): According to the capacity

- Dimension(L*W*H): According to the capacity

- Weight: According to the capacity

- Key word: oil refining equipment

- Supplier type: Factory(more than 35 years experience)

- Capacity: 1-50T/D

- Materials: Carbon steel Q235 and stainless steel SS304/316

- Services: Three-D design and turnkey project

- After-sale services: Installation, debugging,trainning your workers

- Moisture and volatile: 0.08%

- Advantage: Professional engineer team in oil mill plant design

The cost of setting up a palm oil production plant in indonesia is affected by many factors, the approximate cost range is $5000,0-$5,000,000. The most critical influencing factor is what kind of palm oil extraction equipment to purchase.

Find here online price details of companies selling Palm Oil Refinery. Get info of suppliers, manufacturers, exporters, traders of Palm Oil Refinery for buying in indonesia.

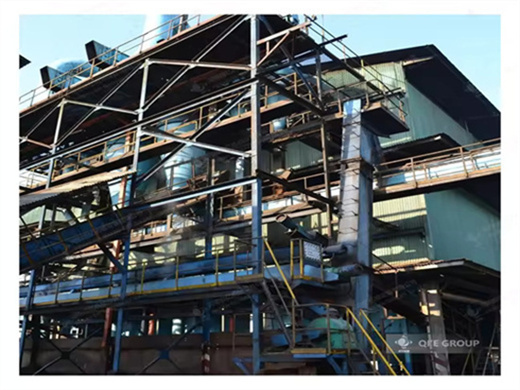

Indonesia’S First Integrated Oil Palm Processing Unit By 3F Oil Processing Machine

- Usage: Dinter crude Cooking oil refinery line

- Type: Cooking Oil Refinery Machine

- Production Capacity: 100TPD caster oil plant

- Voltage: 220V/380V/440V

- Power(W): depend on capacity

- Dimension(L*W*H): depend on capacity

- Weight: depend on capacity

- After-sales Service Provided: Overseas service center available

- Keywords: Dinter crude Cooking oil refinery line

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: oil extraction machine

- oil rate: 20%-98%

This integrated Oil Palm project will include a cutting-edge oil palm factory (Palm Oil Processing and Refinery), a zero-discharge effluent plant, a palm waste-based power plant, and additional structures and go-downs for support purposes. This factory marks the first Oil Palm factory in Arunachal Pradesh and indonesia's first Oil Palm Factory under NMEO-OP.

The refined palm oil can be stored for 18 months after filling and capping and protected from light, but the oil from the oil press, without refining, is difficult to keep for a long time, and it is expected that the index will be exceeded in about 10 days, so it is necessary to refine the oil from the press.

Oil Refineries &Amp; Extraction Plants Manufacturers, Supplier

- Usage: Linseed oil

- Type: Small oil refinery

- Production Capacity: 30-200TPD

- Voltage: 380V/50HZ

- Power(W): according to capacity

- Dimension(L*W*H): according to capacity

- Weight: according to capacity

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Color: According to you

- Power: Electricity

- Continuity: Semi-continuous

- Equipment material: Stainless steel

- Steam consumption: 450KG/T oil

- Electric consumption: 28Kwh/T oil

- Phosphoric acid: 2~3 kg/T oil

- Circulating water cooling water yield: 150m³/H

- Bleaching earth consumption: 5~50Kg/T oil

Brissun Technologies Pvt Ltd is a globally established engineering & manufacturing organization with expertise in Oil Refineries Plant, Edible oil mill refinery & extraction plants manufacturers, supplier & Exporter From indonesia

Palm Oil Production Process: A Step-By-Step Guide

- Usage: for Cooking oil refining mchine

- Type: Cooking Oil Refinery Machine

- Production Capacity: 45 sets per year

- Voltage: 380V/440V

- Power(W): 30KW

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 500TON

- Usage: for Cooking oil refining mchine

- oil clolor: yellow

- advantage: save energy

- bleaching earth consumption: 5-50kg/t oil

- decolor function: remove the bad color

- deodor function: remove the bad smell

- Capacity: according customer request for Cooking oil

- Raw material: crude Cooking oil

Used 30,000 tons/year (100 tons/day) edible oil refinery. Most equipment made during 2009 / 2010 . Shutdown took place end of 2012 / beginning of 2013. The refinery includes: The following storage capabilities: Crude oil 4,000 tons; Refined Edible Oil 1,000 tons; Final product of 1,200 tons. Bottle filling equipment with capacity 4000

Batch-type edible oil refining equipment is ideal for small-scale operations, offering flexibility, efficiency, and high-quality output. Our Batch-Type Edible Oil Refining plants are designed for capacities ranging from 1 ton per day (TPD) to 20 TPD, making them suitable for small producers and pilot operations.

This stage involves careful quality control and adherence to strict regulations to ensure that the palm oil meets the required standards for use in various applications. Palm Oil Powerhouse: QIYI Machinery's Superior Palm Oil Milling Solutions . QIYI Machinery is a leading manufacturer specializing in palm oil milling equipment.

- How do Indonesian oil palm companies carry out efficiency?

- Many oil palm companies carry out efficiency by reducing production capacity and applying economization in various sectors. Lots of Indonesian oil palm companies which have successfully faced this heavy pressure, particularly large sized companies which have already controlled strongly local and international markets.

- What is Indonesia's oil palm plantation & processing industry?

- Indonesia's oil palm plantation and processing industry is a key industry to the country's economy: the export of palm oil is an important foreign exchange earner while the industry provides employment opportunities to millions of Indonesians.

- How big is Indonesia's palm oil refining capacity?

- Palm oil refining capacity in Indonesia is understood to have jumped to (an annual) 45 million tons by the start of 2015, up from an 30.7 million in 2013, and more than double the 21.3 million in 2012. The Government's Palm Oil Tax Policy

- How is palm oil produced in Indonesia?

- Currently, the dominant palm oil production processes in Indonesia are modern, and these large mills typically employ continuous sterilization, threshing, and pressing processes to extract oil from the palm fruit bunches (As noted earlier).

- Who is CDMI – Indonesian oil palm & refinery Directory?

- Viewing the dynamics of oil palm industry in the last several years, CDMI as a consultant company with expertise in data compilation is attracted to perform an investigation for six months towards oil palm companies in the country and finally succeeded in publishing a book with the title of Indonesian OIL PALM & REFINERY Directory, 2017.

- Why is palm oil important in Indonesia?

- In terms of agriculture, palm oil is the most important industry of Indonesia contributing between 1.5 - 2.5 percent of the nation's gross domestic product (GDP). Almost 70 percent of Indonesia's oil palm plantations are located on Sumatra where the industry was started during the Dutch colonial days.