Palm Oil Company And Mill In Indonesia Pt Mahkota Group Tbk

- Usage: Cooking Oil

- Type: For refined Cooking oil machinery usage

- Production Capacity: 100-500 ton

- Voltage: 380V 440V

- Power(W): As refined Cooking oil machinery output every day

- Dimension(L*W*H): Depend on refined Cooking oil machinery capacity

- Weight: As per refined Cooking oil machinery output

- Item: Refined Cooking oil machinery

- Material: Stainless steel

- Refining process: Degumming, Bleaching, Deodorizatizing

- Grades of refined Cooking oil: one grade, two grade, three grade,

- Temperature of deodorization: 280degree

- Consumption of white clay: 1-3%

- Phosphoric acid: 0.2-0.3%

- Soften water: 150kg /ton

- Alkali consumption: 0.8-1.5kg /ton crude oil

- Circulating water: 1-2cm3 /ton crude oil

Mahkota Group mulai bangun pabrik refinery di Dumai. ILUSTRASI, Dirut PT. Mahkota Group, Tbk Usli Sarsi. KONTAN.CO.ID JAKARTA. PT Mahkota Group Tbk mulai melakukan pembangunan proyek refinery penghasil minyak goreng dan kernel crushing plantdi Dumai. Pabrik refinery ini ditargetkan beroperasi pada Juni 2019.

L-Project in Oil Refinery Unit II Dumai Project. Detail Project : Project Owner: PT. Patra-SK; Main Contractor : SK Engineering & Construction; Sub-Contractor: PT. SSA (Sepuluh Submer Anugerah) Project Location : Dumai, Riau Sumatera Islands; Scope of Work : Field Piping Work, Mechanical Work, Shop Tank Fabrication & Field Erection Work

Sejarah Umum Pt. Pertamina Refinery Unit Ii Dumai 123Dok

- Usage: Cooking Oil refinery machine

- Type: Cooking Oil Refinery Machine, Cooking oil refinery machine

- Production Capacity: 10-3000TPD

- Voltage: 220V 380V, Adjustable

- Power(W): According to the capacity

- Dimension(L*W*H): According to the capacity

- Weight: According to the capacity

- Brand: LD

- Oil grade: Grade 1

- Residual oil in meal: ≤ 1%

- Steel type: Carbon steel or 304 steel

- Process: Degumming, deacidification, decoloration, deodorization

- Turnkey Project: YES

- Engineers abroad service: Available

- After sales service: Available

- Warranty: 5 years

Fasilitas Tanki Penimbun dan Dermaga Baru Sumber: HSC Production RU II Dumai Seiring dengan kebutuhan bahan bakar minyak nasional, yang semakin tinggi, pada tahun 1992 dilakukan beberapa modifikasi peralatan kilang sehingga kapasitas olah kilang Pertamina Refinery Unit II Dumai dinaikkan menjadi 120.000 Barrel per hari. 43 Pada tahun 2007

We would like to show you a description here but the site won’t allow us.

Apical Group Invests Us$1 Billion To Expand Palm Oil Production Line

- Usage: Cooking oil, oil making machine

- Type: Cooking oil making machine, oil machine

- Production Capacity: 100%

- Voltage: 400/380/220V

- Power(W): 36KW

- Dimension(L*W*H): 15*12*10 meter

- Weight: 5600kg

- Power: Electricity/water/steam

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Certifate: ISO&BV&CE

- Operating: Easy operate

- Brand: DOING

- Made in: China

- Color: According to customers

In line with the Indonesian government’s industrialization program, Apical Group, a front-runner in vegetable oil processing, particularly palm oil, announced a significant expansion through a US$1 billion investment in Dumai, Riau, which commenced at the end of 2021.

Jakarta,ruangenergi.com- PT Pertamina melalui PT Kilang Pertamina Internasional (PT KPI) Refinery Unit (RU) Dumai melakukan ekspor produk Marine Fuel Oil (MFO).. Produksi MFO Low Sulfur merupakan salah satu inisiatif dalam rangka peningkatan margin kilang Dumai sesuai dengan aturan Pemerintah yang menegaskan bahwa setiap kapal baik kapal berbendera Indonesia maupun kapal asing yang beroperasi

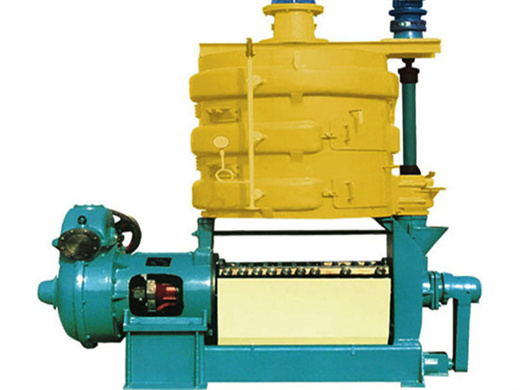

Pertamina Commissions Joint Study On Dumai Oil Refinery Machine

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 7.5kw

- Dimension(L*W*H): Based on Oil Press Machine capacity

- Weight: 1200kg

- Product name: High quality oil refinery plant construction companys

- Advantage: Energy Saving

- Warranty period: 12 months

- Application range: Oil -bearing Material

- Function: Refining Vegetable Oil

- Item: Vegetable Oil Refining Machines

- Use for: Vege

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Section: Oil Refinery Machine Section

- Product: National Oil Standard

Pertamina owns six refinery units with a combined capacity of 1.046,70 thousand barrels.The Dumai oil refinery has an installed capacity of 170,000 barrels per day (bpd). “The project with a value of USD1.5 billion can increase domestic oil and fuel production capacity, so that it will reduce the dependence on Indonesian oil imports which are

Pengaruh Motivasi Kerja Terhadap Pelaksanaan Program ..

- Usage: Cooking

- Method of refinery:

- Application: Cooking curde oil

- Also suitable for: Crude vegetable,sunflowr seeds,Cooking etc

- Refined oil standard: 1st, 2nd, 3rd,4th oil

- Capacity: 30-50T/D ; 10-800 T/D all available

- Heating way: Conduction oil

- Material of equipment: Carbon steel and stainless steel

- bolier: steam boiler

PT. Pertamina (Persero) Refinery Unit II Dumai. Jalan Putri Tujuh, Dumai Riau pada bulan Juli-November 2013. Sampel dalam penelitian ini adalah 75 karyawan. Data primer diperoleh dengan melakukan wawancara kepada karyawan PT.Pertamina (Persero) Refinery Unit II Dumai di Unit Heavy Oil Complex (HOC) dengan merujuk

- How much oil does Afghanistan have?

- Currently private sector refineries have the capacity to refine half of total oil supply of Afghanistan, with combined capacity of 32,500 barrels per day. Afghanistan has estimated reserves of 1,908 million barrels of crude oil + 59 trillion cm of natural gas + 667 million barrels of liquid gas.

- How many tons a day does Ghazanfar oil refinery produce?

- Ghazanfar Oil Refinery has an operating capacity of 500 metric tons per day or 150,000 metric tons per year. Using low sulfur crude, oil distillates and other oil derivatives, the refinery and processing units will produce petrol A-80, Kerosene, Diesel and Mazut.

- What is the oil & gas industry in Afghanistan?

- Our petroleum storage facilities are of international standard with a total storage capacity over 115,000 m3. The oil & gas sector in Afghanistan is rapidly changing. With the Amu Darya Basin in production, Afghanistan is an oil producing nation again.

- What types of petrol will be produced by the refinery & processing units?

- Using low sulfur crude, oil distillates and other oil derivatives, the refinery and processing units will produce petrol A-80, Kerosene, Diesel and Mazut. Through additional processes, we will be producing winterized diesel and high octane petrol.

- Where is Ghazanfar oil refinery located?

- The Ghazanfar Oil Refinery is located in Hairaton City in Northern Afghanistan. Our refinery is situated by the Ghazanfar Dry Port and near the main rail with railway transportation networks into Central Asia and trucking networks reaching throughout Afghanistan.

- Is flgE a profitable business in Afghanistan?

- We therefore recommend the formation of the Afghan Petroleum and Gas Authority to oversee the industry Afghanistan’s national oil state-owned enterprise FLGE is currently a profitable business. The company generates $4.5 million (1393) in revenue. The company owns 238,023 MTs of oil and gas capacity and 94 trucks.